Team:SouthBend-Mishawaka-HS-2/Modeling

From 2011.igem.org

(Difference between revisions)

Bmiramontes (Talk | contribs) |

|||

| (2 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

[[Image:SouthBend-Mishawaka-HS-2_logo.png|200px|center|frame]] | [[Image:SouthBend-Mishawaka-HS-2_logo.png|200px|center|frame]] | ||

| - | |||

{| style="color:#008080;background-color:#7CFC00;" cellpadding="3" cellspacing="1" border="1" bordercolor="#fff" width="62%" align="center" | {| style="color:#008080;background-color:#7CFC00;" cellpadding="3" cellspacing="1" border="1" bordercolor="#fff" width="62%" align="center" | ||

| Line 13: | Line 12: | ||

!align="center"|[[Team:SouthBend-Mishawaka-HS-2/Attributions|Attributions]] | !align="center"|[[Team:SouthBend-Mishawaka-HS-2/Attributions|Attributions]] | ||

|} | |} | ||

| - | |||

| - | ==='''Diagram Explaination''' | + | ='''A3 Assembly'''= |

| + | |||

| + | [[File:mynameisjoe.jpeg|center]] | ||

| + | |||

| + | ='''Diagram Explaination'''= | ||

<br> | <br> | ||

| - | = The above diagram is an example of the A3 Assembly that we used to combine to basic parts into a composite part. This one shows the creation of K675004 that has the ArsR-regulated promoter coupled to the GFP generator. Both parts assemble in the right order because of the way that they are cut with restriction enzymes. They only have one plasmid that they can go into and that one is tetracycline resistant so we selected for the transformed bacteria with tetracycline. After a while we chose large colonies and grew them in LB-AMP because they could grow quicker and we could extract more DNA. We ran the parts that we made on argarose gel electrophoresis to check the sizes. | + | <font size="4"> The above diagram is an example of the A3 Assembly that we used to combine to basic parts into a composite part. This one shows the creation of K675004 that has the ArsR-regulated promoter coupled to the GFP generator. Both parts assemble in the right order because of the way that they are cut with restriction enzymes. They only have one plasmid that they can go into and that one is tetracycline resistant so we selected for the transformed bacteria with tetracycline. After a while we chose large colonies and grew them in LB-AMP because they could grow quicker and we could extract more DNA. We ran the parts that we made on argarose gel electrophoresis to check the sizes. </font> |

https://static.igem.org/mediawiki/2010/d/d2/IGEM_official_gray4.png | https://static.igem.org/mediawiki/2010/d/d2/IGEM_official_gray4.png | ||

Latest revision as of 15:29, 24 June 2011

| Home | Team | Official Team Profile | Project | Parts Submitted to the Registry | Modeling | Notebook | Safety | Attributions |

|---|

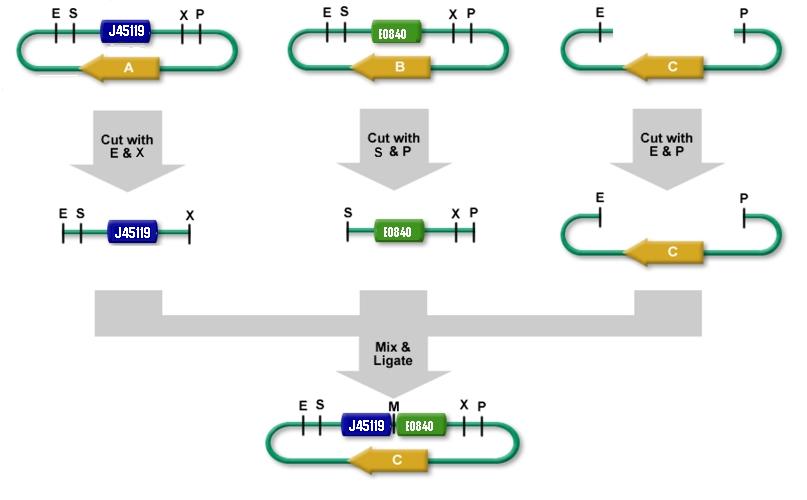

A3 Assembly

Diagram Explaination

The above diagram is an example of the A3 Assembly that we used to combine to basic parts into a composite part. This one shows the creation of K675004 that has the ArsR-regulated promoter coupled to the GFP generator. Both parts assemble in the right order because of the way that they are cut with restriction enzymes. They only have one plasmid that they can go into and that one is tetracycline resistant so we selected for the transformed bacteria with tetracycline. After a while we chose large colonies and grew them in LB-AMP because they could grow quicker and we could extract more DNA. We ran the parts that we made on argarose gel electrophoresis to check the sizes.

"

"