Team:ETH Zurich/Process/Microfluidics

From 2011.igem.org

(→Microfluidic channel without flow) |

(→Microfluidic channel with flow and recycling of the medium) |

||

| Line 31: | Line 31: | ||

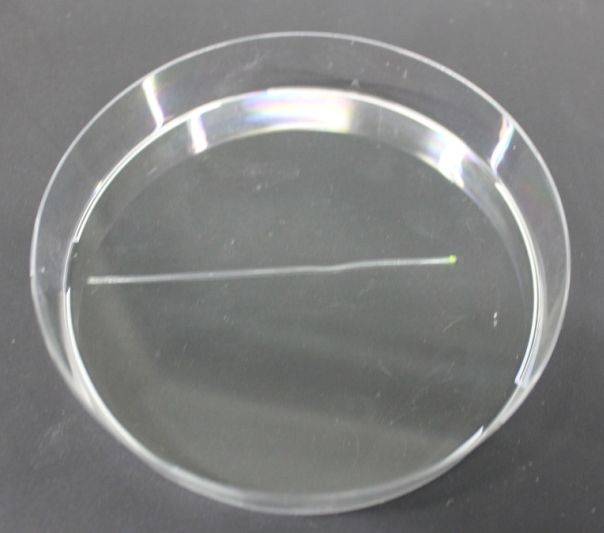

* '''Variant 2: Microfluidic channel with cells sitting in pockets in the channel. '''This channel design only consists of one part: A PDMS channel that is fixed onto a glass carrier. The PDMS channel contains pockets which hold the cells given a constant flow from the direction of the "open end" of the pockets. This channel design does not have the advantages of the above one, i.e. it is not as robust and cell density cannot be reliably varied. However, manufacturing it is a standard process and thus easier. | * '''Variant 2: Microfluidic channel with cells sitting in pockets in the channel. '''This channel design only consists of one part: A PDMS channel that is fixed onto a glass carrier. The PDMS channel contains pockets which hold the cells given a constant flow from the direction of the "open end" of the pockets. This channel design does not have the advantages of the above one, i.e. it is not as robust and cell density cannot be reliably varied. However, manufacturing it is a standard process and thus easier. | ||

[[File:flowchannel_pockets.png|400px|center|thumb|'''Experimental setup for SmoColi.''' ]]<br clear="all" /> | [[File:flowchannel_pockets.png|400px|center|thumb|'''Experimental setup for SmoColi.''' ]]<br clear="all" /> | ||

| + | A problem with both of these designs is that for the AHL-based RFP alarm to work, recycling of the flow back into the channel would be required. Since the tubing and pumps would have very high volumes compared to the channel volume, the AHL signal would be diluted to the point where no detection is possible anymore. Also, several pumps would be required to accomplish this, further complicating the process design and making it more error-prone. | ||

|} | |} | ||

Revision as of 02:00, 22 September 2011

| Microfluidics |

| ||

|

We relatively early figured out that we need some kind of channel to establish the acetaldehyde or xylene gradient required for SmoColi (see Circuit Design). However, there were several different possible channel designs, and the final design evolved through an iterative series of design steps and design validations. The first designs were validated based on vast simulations, the final design furthermore by biological experiments in the lab (see Systems Validation). | |||

Initial Channel DesignsMicrofluidic channel with flow and recycling of the mediumWe came up with two different possible microfluidic channel designs, both involving a flow of toxic molecule in medium through the channel:

A problem with both of these designs is that for the AHL-based RFP alarm to work, recycling of the flow back into the channel would be required. Since the tubing and pumps would have very high volumes compared to the channel volume, the AHL signal would be diluted to the point where no detection is possible anymore. Also, several pumps would be required to accomplish this, further complicating the process design and making it more error-prone. |

"

"