Team:Bielefeld-Germany/Results/BPA

From 2011.igem.org

(→Interpretation of the results) |

(→Model for the fusion protein between FNR, BisdA and BisdB) |

||

| (6 intermediate revisions not shown) | |||

| Line 38: | Line 38: | ||

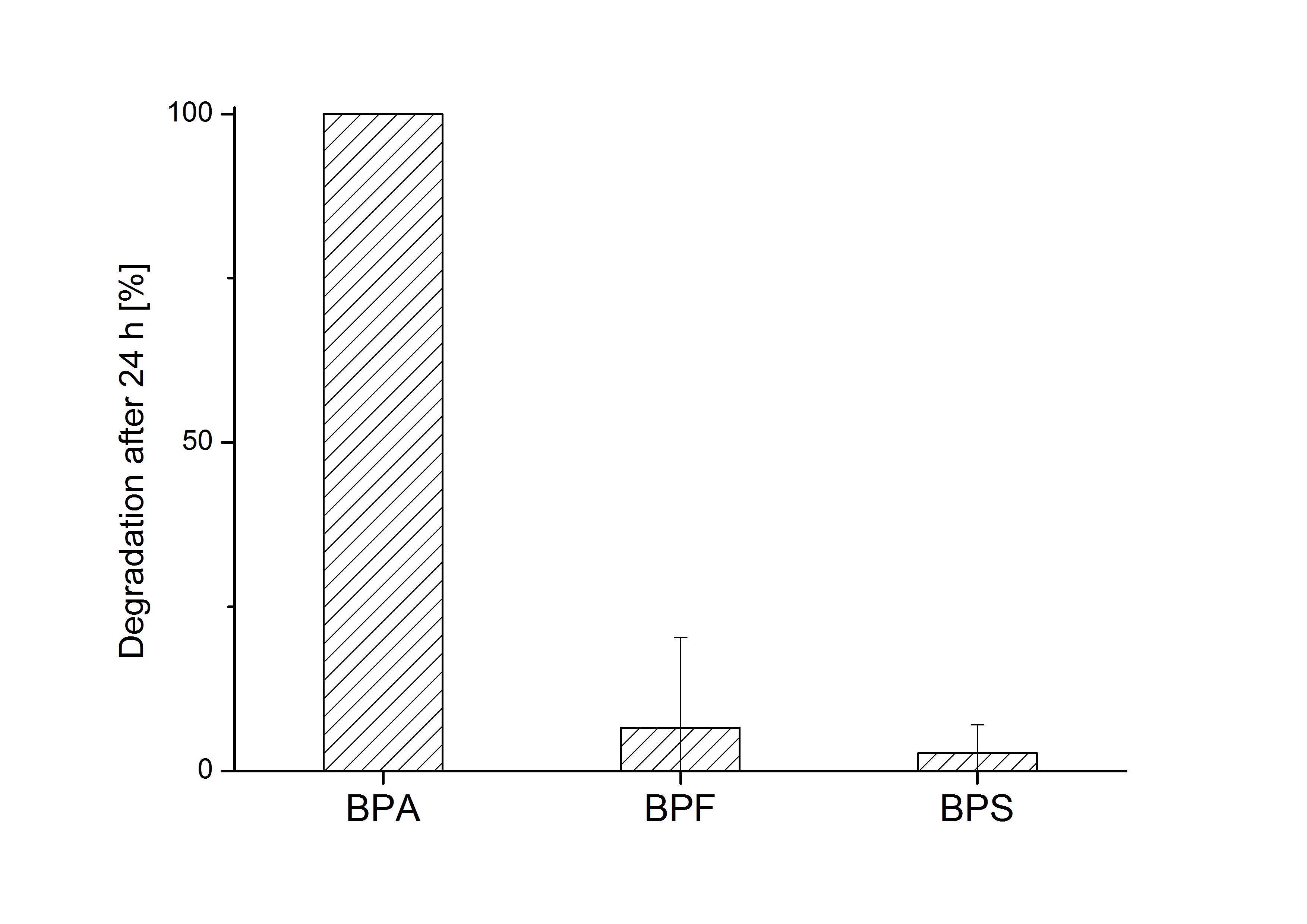

''E. coli'' KRX carrying genes for the bisdA | bisdB fusion protein behind the medium strong constitutive promoter <partinfo>J23110</partinfo> with RBS <partinfo>B0034</partinfo> was cultivated at 30 °C for 36 h with LB-Medium containing 120 mg L<sup>-1</sup> BPA, BPF respectively BPS. The BPF and BPS concentration were determined with a HPLC using the same method as with BPA. Figure 8 shows the degradation of the respective bisphenol after 24 h of cultivation in percent. | ''E. coli'' KRX carrying genes for the bisdA | bisdB fusion protein behind the medium strong constitutive promoter <partinfo>J23110</partinfo> with RBS <partinfo>B0034</partinfo> was cultivated at 30 °C for 36 h with LB-Medium containing 120 mg L<sup>-1</sup> BPA, BPF respectively BPS. The BPF and BPS concentration were determined with a HPLC using the same method as with BPA. Figure 8 shows the degradation of the respective bisphenol after 24 h of cultivation in percent. | ||

| - | [[Image:Bielefeld_2011_517_BPA-BPF-BPS_Degradation_24h_2.png|500px|center|thumb| '''Figure 8: Degradation of BPA, BPF and BPS after 24 h cultivation with ''E.coli'' KRX carrying genes for the bisdA <html>|</html> bisdB fusion protein behind the medium strong constitutive promoter <partinfo>J23110</partinfo> with RBS <partinfo>B0034</partinfo>. [[Team:Bielefeld-Germany/Protocols/Downstream-processing#Expression_of_bisphenol_A_degrading_BioBricks_in_E._coli | Cultivations]] were carried out at different temperatures in LB + Amp + bisphenol medium (starting concentration 120 mg L-1 BPA, BPF or BPS respectively) for 24 h in 300 mL shaking flasks without baffles with silicon plugs. Samples were taken | + | [[Image:Bielefeld_2011_517_BPA-BPF-BPS_Degradation_24h_2.png|500px|center|thumb| '''Figure 8: Degradation of BPA, BPF and BPS after 24 h cultivation with ''E.coli'' KRX carrying genes for the bisdA <html>|</html> bisdB fusion protein behind the medium strong constitutive promoter <partinfo>J23110</partinfo> with RBS <partinfo>B0034</partinfo>. [[Team:Bielefeld-Germany/Protocols/Downstream-processing#Expression_of_bisphenol_A_degrading_BioBricks_in_E._coli | Cultivations]] were carried out at different temperatures in LB + Amp + bisphenol medium (starting concentration 120 mg L<sup>-1</sup> BPA, BPF or BPS respectively) for 24 h in 300 mL shaking flasks without baffles with silicon plugs. Samples were taken every 3 hours. Two biological replicates were analyzed (n=2). While BPA is fully degraded only a small fraction of BPF (~7%) and BPS (~3%) was degraded.''']] |

| - | The results of the experiment indicate that the bisdA | bisdB fusion protein has a '''high specificity for the degradation of BPA'''. In addition it is possible that the decrease in BPF and BPS concentration is due to internalization of those bisphenols or a endogenous enzyme of ''E. coli'' KRX and | + | The results of the experiment indicate that the bisdA | bisdB fusion protein has a '''high specificity for the degradation of BPA'''. In addition it is possible that the decrease in BPF and BPS concentration is due to internalization of those bisphenols or a endogenous enzyme of ''E. coli'' KRX and that the bisdA | bisdB fusion protein was not responsible. It can be assumed that false positive signals because of BPF or BPS present in a sample are unlikely. |

===BPA degradation with constructs containing FNR=== | ===BPA degradation with constructs containing FNR=== | ||

| Line 64: | Line 64: | ||

We are especially impressed that the '''fusion protein of FNR, BisdA and BisdB''' (<partinfo>K525560</partinfo>) not only was '''capable to degrade BPA''' but also was '''the fastest construct''' we employed. This also contributes to the feasibility of our approach for a cell free BPA biosensor since in a cell free environment fusion proteins are beneficial when compared to their non-fused counterparts. | We are especially impressed that the '''fusion protein of FNR, BisdA and BisdB''' (<partinfo>K525560</partinfo>) not only was '''capable to degrade BPA''' but also was '''the fastest construct''' we employed. This also contributes to the feasibility of our approach for a cell free BPA biosensor since in a cell free environment fusion proteins are beneficial when compared to their non-fused counterparts. | ||

| - | == | + | ==Modeling of intracellular bisphenol A degradation== |

===Regular model=== | ===Regular model=== | ||

| - | The | + | The modeling was done with the software [http://www.berkeleymadonna.com/ Berkeley Madonna] using the [http://en.wikipedia.org/wiki/Runge–Kutta_methods#Common_fourth-order_Runge.E2.80.93Kutta_method common fourth-order Runge-Kutta] method to solve the equations. The model was fitted to the measured data shown above by the function "curve fit" in Berkeley Madonna to calculate the parameters, constants, ''etc.''. |

To model the BPA degradation by ''E. coli'' carrying BioBricks for BPA degradation (<partinfo>K123000</partinfo> and <partinfo>K123001</partinfo>), first the cell growth has to be described to calculate a specific BPA degradation rate per cell. The observed growth of ''E. coli'' on (our) LB medium was [http://en.wikipedia.org/wiki/Diauxie diauxic] with two different growth phases. Cell growth is a [http://en.wikipedia.org/wiki/First_order_kinetics#First-order_reactions first-order reaction] and is mathematically described as | To model the BPA degradation by ''E. coli'' carrying BioBricks for BPA degradation (<partinfo>K123000</partinfo> and <partinfo>K123001</partinfo>), first the cell growth has to be described to calculate a specific BPA degradation rate per cell. The observed growth of ''E. coli'' on (our) LB medium was [http://en.wikipedia.org/wiki/Diauxie diauxic] with two different growth phases. Cell growth is a [http://en.wikipedia.org/wiki/First_order_kinetics#First-order_reactions first-order reaction] and is mathematically described as | ||

| Line 76: | Line 76: | ||

| - | with the '''specific growth rate''' '''µ''' and the '''cell count''' '''X'''. The specific growth rate is dependent on the concentration of the growth limiting substrate (e.g. glucose) and can be described as | + | with the '''specific growth rate''' '''µ''' and the '''cell count''' '''X'''. The specific growth rate is dependent on the concentration of the growth limiting substrate (''e.g.'' glucose) and can be described as |

| Line 82: | Line 82: | ||

| - | with the '''substrate concentration''' '''S''', the '''Monod constant''' '''K<sub>S</sub>''' and the '''maximal specific growth rate''' '''µ<sub>max</sub>''' ([http://www.annualreviews.org/doi/abs/10.1146/annurev.mi.03.100149.002103 Monod, 1949]). Because LB medium is a complex medium we cannot measure the substrate concentration so we have to assume an imaginary substrate concentration. Due to the diauxic growth two different substrates with different Monod constants and consumption rates are necessary to model the cell growth. The amount of a substrate S can be | + | with the '''substrate concentration''' '''S''', the '''Monod constant''' '''K<sub>S</sub>''' and the '''maximal specific growth rate''' '''µ<sub>max</sub>''' ([http://www.annualreviews.org/doi/abs/10.1146/annurev.mi.03.100149.002103 Monod, 1949]). Because LB medium is a complex medium we cannot measure the substrate concentration so we have to assume an imaginary substrate concentration. Due to the diauxic growth two different substrates with different Monod constants and consumption rates are necessary to model the cell growth. The amount of a substrate S can be modeled as follows |

| Line 94: | Line 94: | ||

| - | The '''specific BPA degradation rate per cell''' '''q<sub>D</sub>''' is | + | The '''specific BPA degradation rate per cell''' '''q<sub>D</sub>''' is modeled with an equation like eq. (3). In the beginning of the cultivations, when ''E. coli'' growths on the "good" imaginary substrate S<sub>1</sub>, no BPA degradation is observed. When this substrate is consumed, the BPA degradation starts. The model for this diauxic behavior is as follows: |

| Line 100: | Line 100: | ||

| - | Figures 9 - 12 show a comparison between | + | Figures 9 - 12 show a comparison between modeled and measured data for cultivations with BPA degrading ''E. coli''. In Table 1 the parameters for the model are given, obtained by curve fitting the model to the data. |

| - | + | ||

===Model for the fusion protein between FNR, BisdA and BisdB=== | ===Model for the fusion protein between FNR, BisdA and BisdB=== | ||

| - | The cultivations and BPA degradation of ''E. coli'' KRX carrying a fusion protein consisting of ferredoxin-NADP<sup>+</sup> oxidoreductase, ferredoxin<sub>bisd</sub> and cytochrome P450<sub>bisd</sub> differ from the cultivations with the other BPA degrading BioBricks. Thus, the model for these cultivations has to be adjusted to this behaviour. First of all, no diauxic growth is observed so the growth can be | + | The cultivations and BPA degradation of ''E. coli'' KRX carrying a fusion protein consisting of ferredoxin-NADP<sup>+</sup> oxidoreductase, ferredoxin<sub>bisd</sub> and cytochrome P450<sub>bisd</sub> differ from the cultivations with the other BPA degrading BioBricks. Thus, the model for these cultivations has to be adjusted to this behaviour. First of all, no diauxic growth is observed so the growth can be modeled more easily like |

| Line 111: | Line 110: | ||

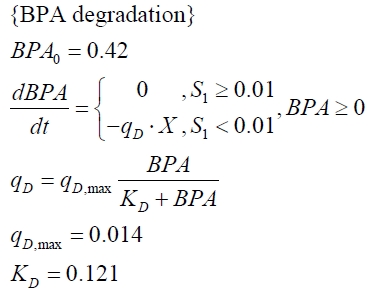

| - | The BPA degradation starts when the imaginary substrate is depleted, like observed in the other cultivations with BPA degrading BioBricks. But it seems that the BPA degradation is getting slower with longer cultivation time. So it is | + | The BPA degradation starts when the imaginary substrate is depleted, like observed in the other cultivations with BPA degrading BioBricks. But it seems that the BPA degradation is getting slower with longer cultivation time. So it is modeled with a Monod-like term in which the specific BPA degradation rate is dependent from the BPA concentration: |

| - | [[Image:IGEM-Bielefeld2011-BPAdegradcomp.jpg|center| | + | [[Image:IGEM-Bielefeld2011-BPAdegradcomp.jpg|center|270px]] <div align="right">(7)</div> |

with the maximal specific BPA degradation rate q<sub>D,max</sub> and the constant K<sub>D</sub>. | with the maximal specific BPA degradation rate q<sub>D,max</sub> and the constant K<sub>D</sub>. | ||

| - | Figures 13 shows a comparison between | + | Figures 13 shows a comparison between modeled and measured data for cultivations with BPA degrading fusion protein ''E. coli''. In Tab. 1 the parameters for the model are given, obtained by curve fitting the model to the data. |

| - | + | ||

| - | ===Comparison between | + | ===Comparison between modeled and measured data=== |

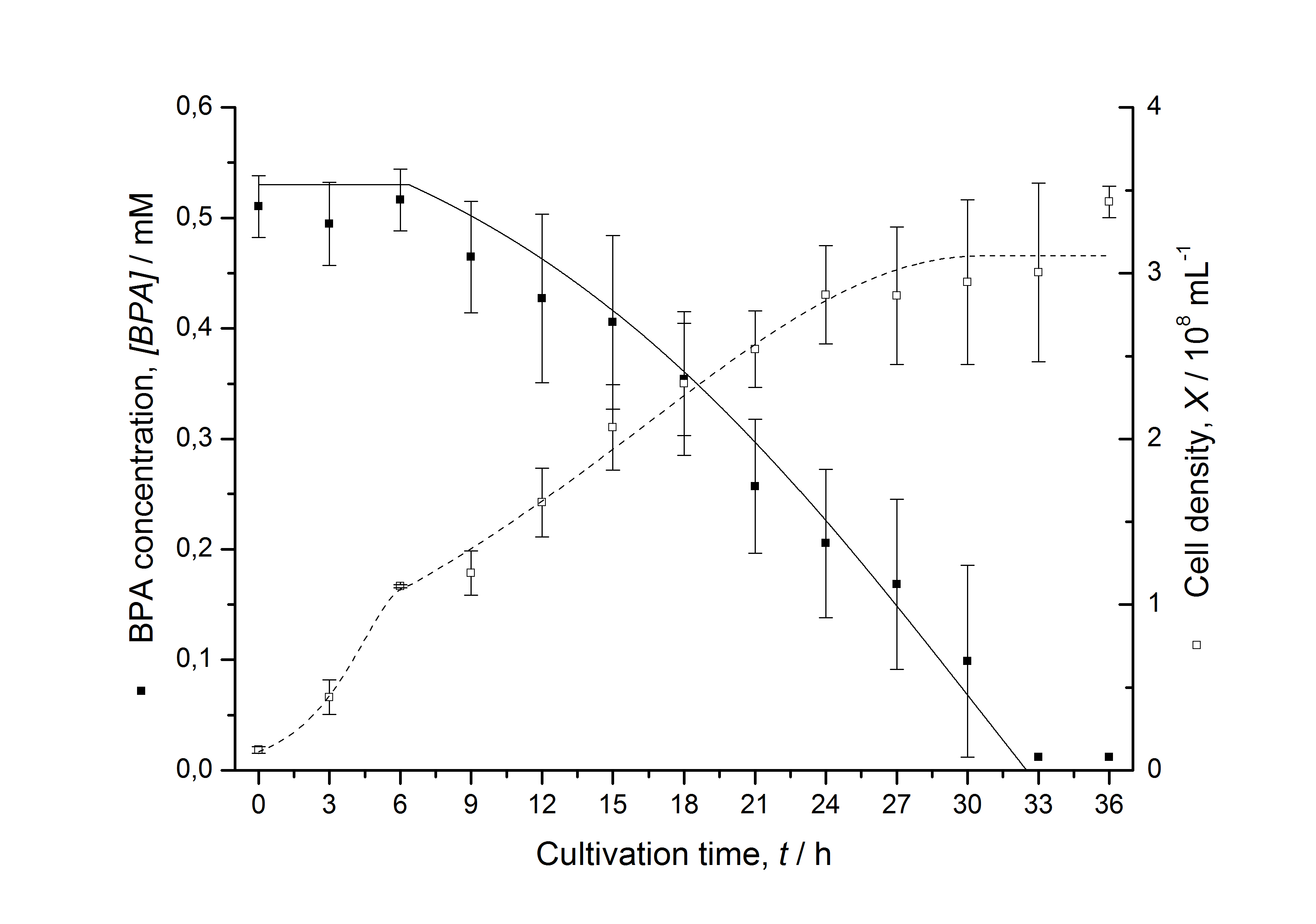

| - | [[Image:IGEM-Bielefeld2011-Modell_K525512.png|left|430px|thumb|'''Figure 12: Comparison between | + | [[Image:IGEM-Bielefeld2011-Modell_K525512.png|left|430px|thumb|'''Figure 12: Comparison between modeled (lines) and measured (dots) data for [[Team:Bielefeld-Germany/Protocols/Downstream-processing#Expression_of_bisphenol_A_degrading_BioBricks_in_E._coli | cultivations]] of ''E. coli'' KRX carrying BPA degrading BioBrick <partinfo>K525512</partinfo>. The BioBrick <partinfo>K525512</partinfo> (polycistronic ''bisdAB'' genes behind medium strong promoter) was cultivated seven times in ''E. coli'' KRX in LB + Amp + BPA medium at 30 °C, using 300 mL shaking flasks without baffles with silicon plugs. The BPA concentration (closed dots) and the cell density (open dots) is plotted against the cultivation time. ''']] |

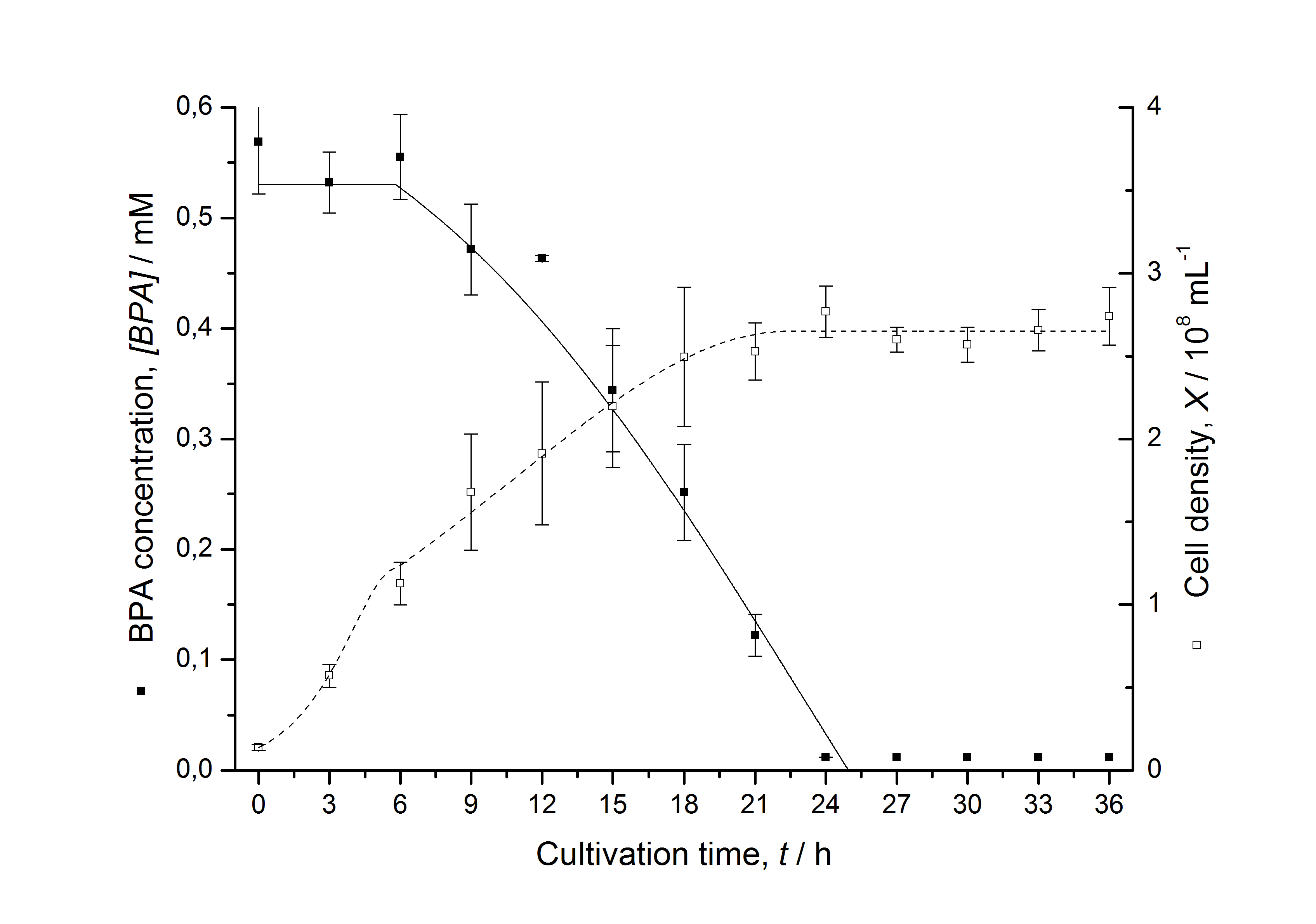

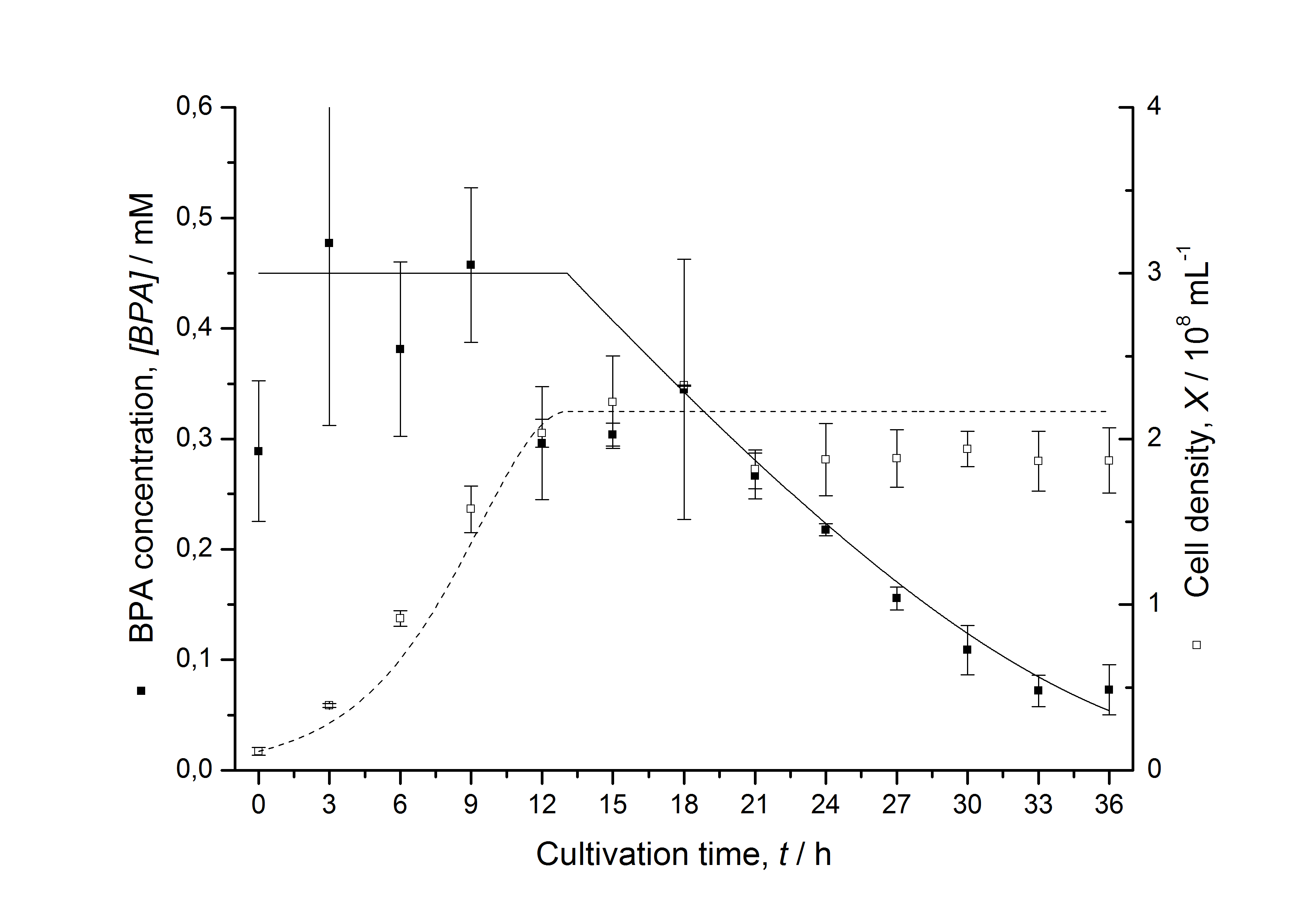

| - | [[Image:IGEM-Bielefeld2011-ModellK525517.png|left|430px|thumb|'''Figure 13: Comparison between | + | [[Image:IGEM-Bielefeld2011-ModellK525517.png|left|430px|thumb|'''Figure 13: Comparison between modeled (lines) and measured (dots) data for [[Team:Bielefeld-Germany/Protocols/Downstream-processing#Expression_of_bisphenol_A_degrading_BioBricks_in_E._coli | cultivations]] of ''E. coli'' KRX carrying BPA degrading BioBrick <partinfo>K525517</partinfo>. The BioBrick <partinfo>K525517</partinfo> (fusion protein between BisdA and BisdB behind medium strong promoter) was cultivated five times in ''E. coli'' KRX in LB + Amp + BPA medium at 30 °C, using 300 mL shaking flasks without baffles with silicon plugs. The BPA concentration (closed dots) and the cell density (open dots) is plotted against the cultivation time. ''']] |

<br style="clear: both" /> | <br style="clear: both" /> | ||

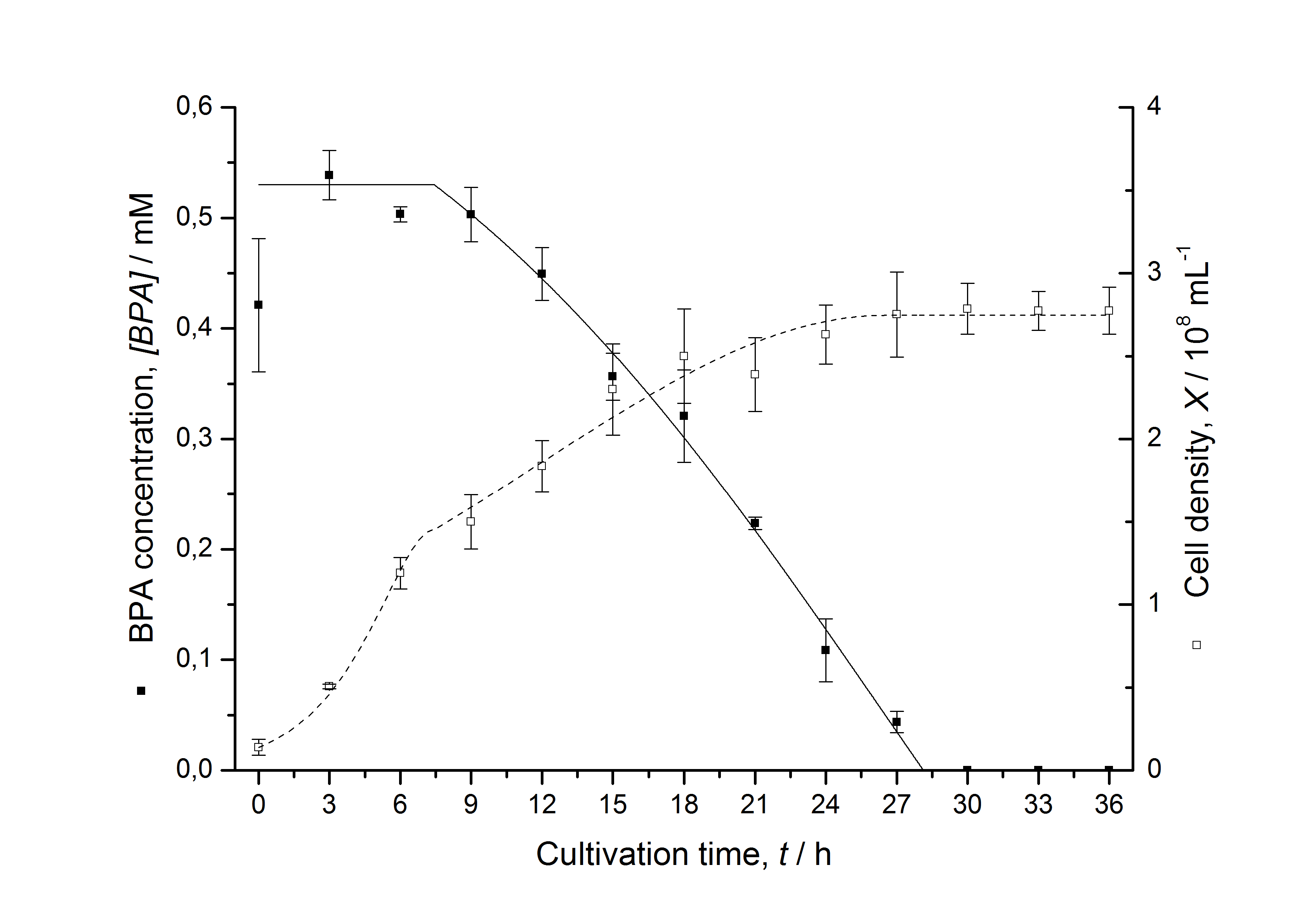

| - | [[Image:IGEM-Bielefeld2011-ModellK525552.png|left|430px|thumb|'''Figure 14: Comparison between | + | [[Image:IGEM-Bielefeld2011-ModellK525552.png|left|430px|thumb|'''Figure 14: Comparison between modeled (lines) and measured (dots) data for [[Team:Bielefeld-Germany/Protocols/Downstream-processing#Expression_of_bisphenol_A_degrading_BioBricks_in_E._coli | cultivations]] of ''E. coli'' KRX carrying BPA degrading BioBrick <partinfo>K525552</partinfo>. The BioBrick <partinfo>K525552</partinfo> (polycistronic ''fnr'' : ''bisdA'' : ''bisdB'' genes behind medium strong promoter) was cultivated four times in ''E. coli'' KRX in LB + Amp + BPA medium at 30 °C, using 300 mL shaking flasks without baffles with silicon plugs. The BPA concentration (closed dots) and the cell density (open dots) is plotted against the cultivation time. ''']] |

| - | [[Image:IGEM-Bielefeld2011-ModellK525582.png|left|430px|thumb|'''Figure 15: Comparison between | + | [[Image:IGEM-Bielefeld2011-ModellK525582.png|left|430px|thumb|'''Figure 15: Comparison between modeled (lines) and measured (dots) data for [[Team:Bielefeld-Germany/Protocols/Downstream-processing#Expression_of_bisphenol_A_degrading_BioBricks_in_E._coli | cultivations]] of ''E. coli'' KRX carrying BPA degrading BioBrick <partinfo>K525582</partinfo>. The BioBrick <partinfo>K525582</partinfo> (polycistronic ''fnr'' : BisdAB (fusion protein) genes behind medium strong promoter) was cultivated four times in ''E. coli'' KRX in LB + Amp + BPA medium at 30 °C, using 300 mL shaking flasks without baffles with silicon plugs. The BPA concentration (closed dots) and the cell density (open dots) is plotted against the cultivation time. ''']] |

<br style="clear: both" /> | <br style="clear: both" /> | ||

| - | [[Image:IGEM-Bielefeld2011-ModellK525562.png|center|430px|thumb|'''Figure 16: Comparison between | + | [[Image:IGEM-Bielefeld2011-ModellK525562.png|center|430px|thumb|'''Figure 16: Comparison between modeled (lines) and measured (dots) data for [[Team:Bielefeld-Germany/Protocols/Downstream-processing#Expression_of_bisphenol_A_degrading_BioBricks_in_E._coli | cultivations]] of ''E. coli'' KRX carrying BPA degrading BioBrick <partinfo>K525562</partinfo>. The BioBrick <partinfo>K525562</partinfo> (fusion protein between FNR, BisdA and BisdB behind medium strong promoter) was cultivated four times in ''E. coli'' KRX in LB + Amp + BPA medium at 30 °C, using 300 mL shaking flasks without baffles with silicon plugs. The BPA concentration (closed dots) and the cell density (open dots) is plotted against the cultivation time. ''']] |

<br style="clear: both" /> | <br style="clear: both" /> | ||

Latest revision as of 03:23, 29 October 2011

Contents |

Sequencing results

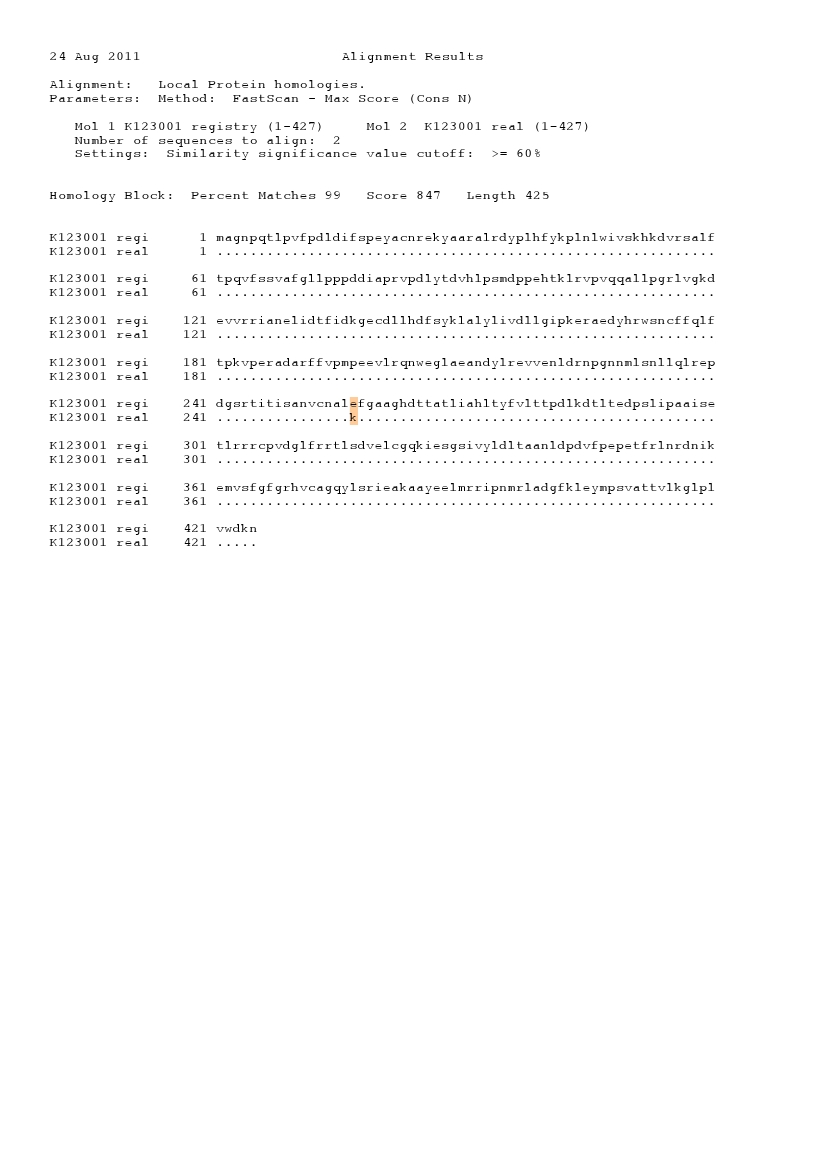

The iGEM team from the University of Alberta sent in BioBricks for BPA degradation in 2008 (<partinfo>K123000</partinfo> and <partinfo>K123001</partinfo>). Sequencing of these BioBricks by the iGEM HQ and by us led to negative results so the sequences entered into the partsregistry are not correct although these sequences are the ones from Sphingomonas bisphenolicum AO1 (compare [http://www.ncbi.nlm.nih.gov/nuccore/AB255167.1 genbank entry]). In addition, there are "illegal" AgeI and NgoMIV restriction sites in the BioBrick which are used for Freiburg BioBrick assembly standard (RFC 25). After translating and comparing the original sequences from the partsregistry and the sequences from our sequencing results in silico, we saw that the amino acid sequences were identical. These BioBricks were probably synthesized in the Freiburg assembly standard 25 because they have the accordant restriction sites and they were codon optimized for Escherichia coli. But the original sequence from S. bisphenolicum AO1 was entered into the registry because amino acid sequence of the real sequence and the sequence that was entered are identical. The alignments are shown in Figures 1 - 4.

Bisphenol A degradation with E. coli

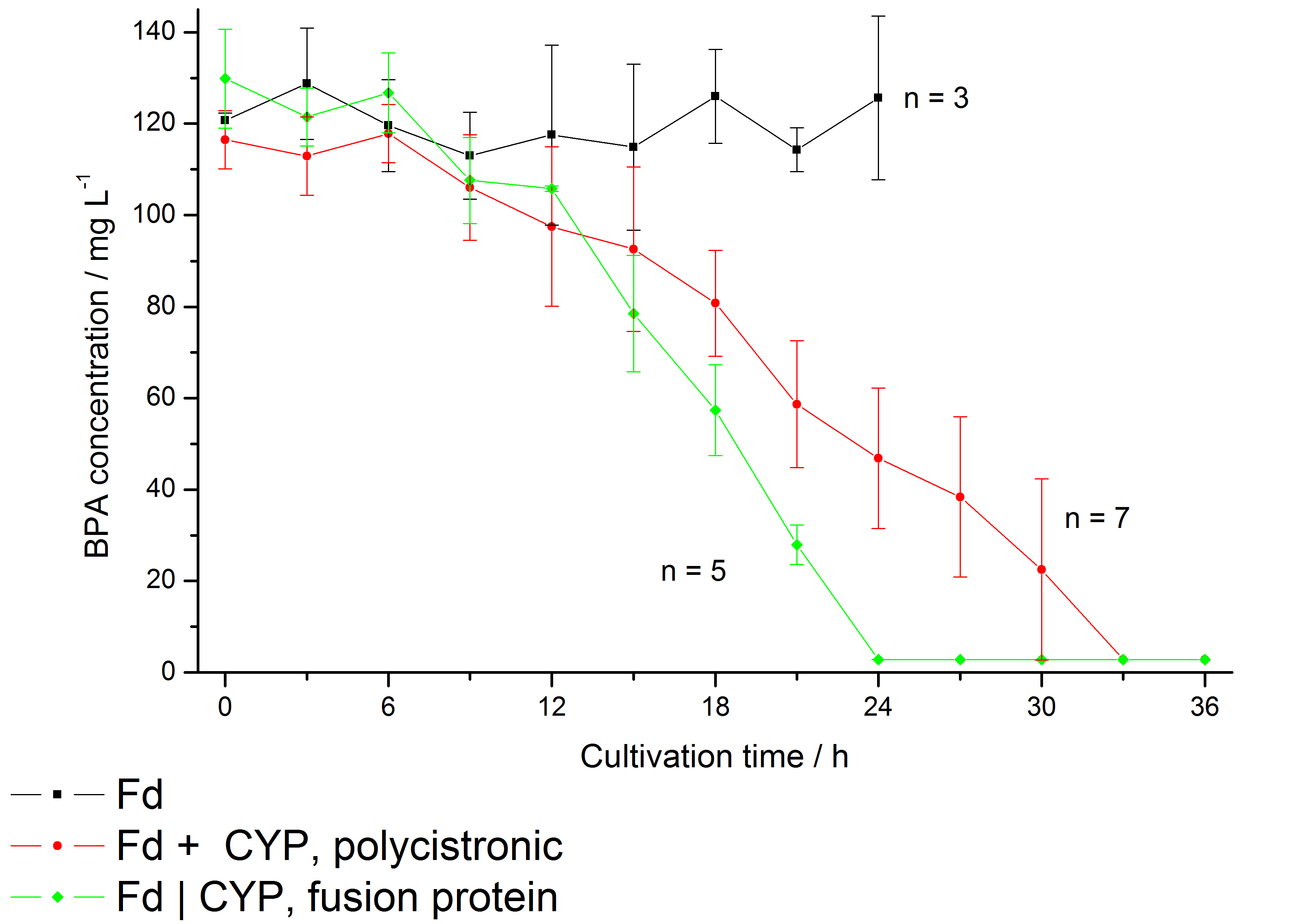

The bisphenol A degradation with the BioBricks <partinfo>K123000</partinfo> and <partinfo>K123001</partinfo> works in E. coli KRX in general. Because [http://onlinelibrary.wiley.com/doi/10.1111/j.1365-2672.2008.03843.x/full Sasaki et al. (2008)] reported problems with protein folding in E. coli which seem to inhibit a complete BPA degradation, we did not cultivate at 37 °C and we did not use the strong T7 promoter as [http://onlinelibrary.wiley.com/doi/10.1111/j.1365-2672.2008.03843.x/full Sasaki et al. (2008)] did for expressing these BioBricks. Instead, we cultivated at 30 °C and we used a medium strong constitutive promoter (<partinfo>J23110</partinfo>). Incidentally, 30 °C is announced as the cultivation temperature of S. bisphenolicum AO1. With the chosen promoter upstream of a polycistronic bisdAB gene, we were able to completely degrade 120 mg L-1 BPA in about 30 - 33 h. By fusing <partinfo>K123000</partinfo> and <partinfo>K123001</partinfo> (using Freiburg BioBrick assembly standard) we could improve the BPA degradation of E. coli even further so that 120 mg L-1 BPA can be degraded in 21 - 24 h. This data is shown in the following figure:

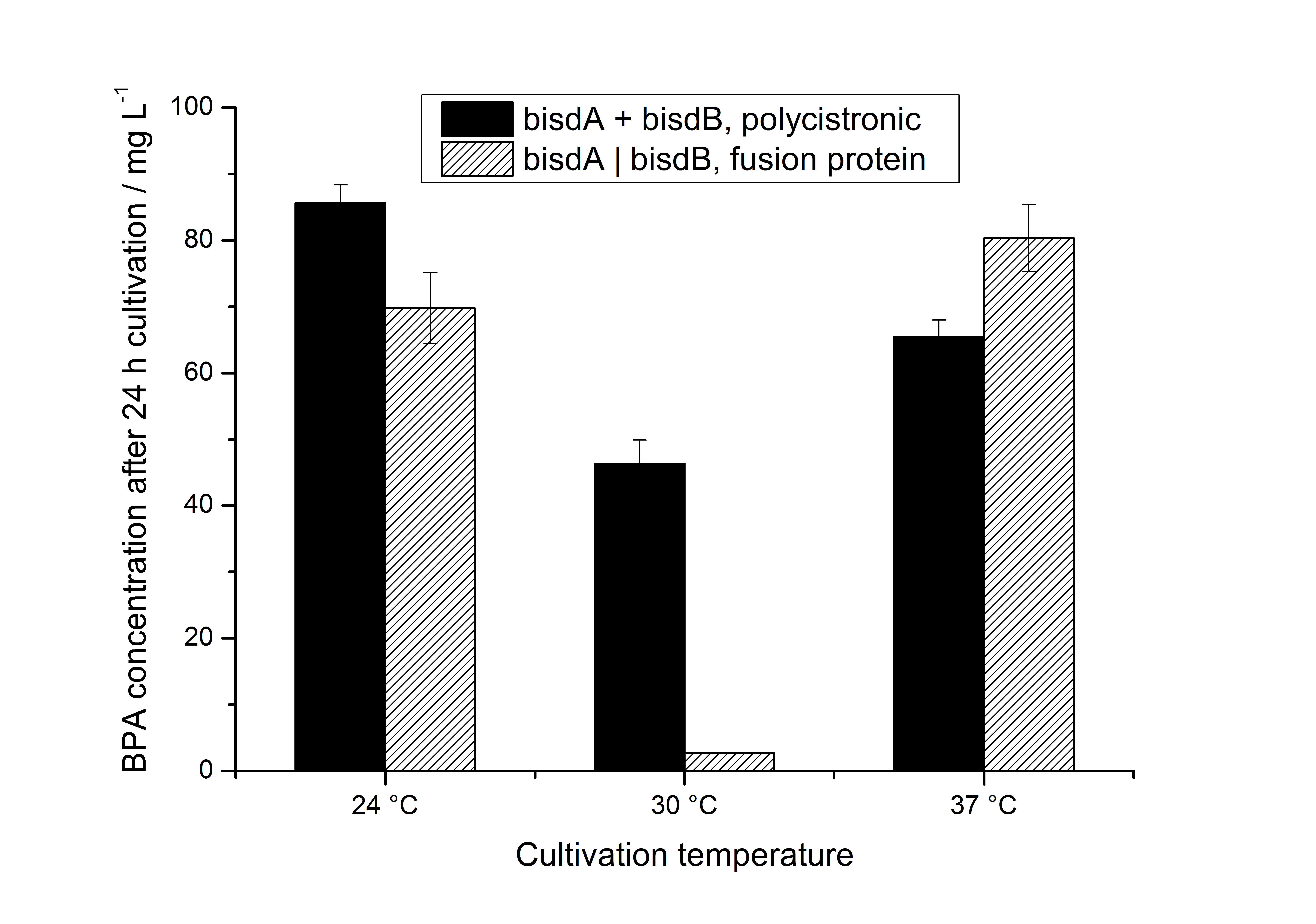

Additionally, we carried out these cultivations at different temperatures and BPA concentrations, but the chosen conditions (30 °C and 120 mg L-1 BPA) seemed to be the best. Higher BPA concentrations had an effect on the growth of E. coli and higher temperature led to a worse BPA degradation (probably due to misfolding of the enzymes). Lower temperature also led to less BPA degradation (probably due to slower growth, expression and reaction rate at lower temperatures). The data dealing with the effect of the temperature on the BPA degradation is shown in Figure 6.

As shown by [http://onlinelibrary.wiley.com/doi/10.1111/j.1365-2672.2008.03843.x/full Sasaki et al. (2008)], BisdB expressed in E. coli leads to almost no BPA degradation. In our experiments, we could not detect the BPA degradation products 1,2-Bis(4-hydroxyphenyl)-2-propanol and 2,2-Bis(4-hydroxyphenyl)-1-propanol in cultivations with E. coli expressing <partinfo>K123000</partinfo> or <partinfo>K123001</partinfo> alone (neither via UV- nor MS-detection). The BPA degradation products 1,2-Bis(4-hydroxyphenyl)-2-propanol and 2,2-Bis(4-hydroxyphenyl)-1-propanol were identified via MS-MS (m/z: 243 / 225 / 211 / 135) and only occured in cultivations with E. coli expressing BisdA and BisdB simultaneously. [http://www.springerlink.com/content/q7864l02734wg32m/ Sasaki et al. (2005)] reported the same MS-MS results for 1,2-Bis(4-hydroxyphenyl)-2-propanol and 2,2-Bis(4-hydroxyphenyl)-1-propanol when degrading BPA with S. bisphenolicum AO1 as we observed in our BPA degradation experiments.

We could also identify the BPA degradation products when working with E. coli TOP10 and MACH1 (data not shown). But because we aim to fuse BisdA and BisdB to S-layer proteins which are supposed to be expressed in E. coli KRX, we carried out the characterizations of <partinfo>K123000</partinfo> and <partinfo>K123001</partinfo> in this strain.

Specificity of bisphenol A degradation with E. coli

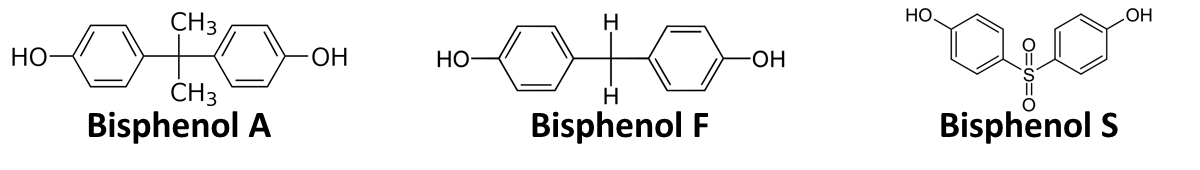

In order to access the specificity of the bisphenol A degradation by the bisdA | bisdB fusion protein we tested how well two similar bisphenols, bisphenol F (BPF) and bisphenol S (BPS), were utilized. The structure of those bisphenols differs only in the chemical group linking the two phenols from that of bisphenol A (see Figure 7).

BPF and BPS are used in a broad range of applications that involve the use of polycarbonates or epoxy resins and thus can often be found were BPA is also present. Accordingly, their presence is a potential disruptive factor that could lead to a false positive signal with our biosensor. This is especially true for BPS that in some cases is used as a substitute for BPA in baby bottles [http://www.nytimes.com/2011/04/18/business/global/18iht-rbog-plastic-18.html]. Studies concerning the environmental pollution with BPF ([http://www.sciencedirect.com/science/article/pii/S0043135401003670 Fromme et al. (2002)]) and the acute toxicity, mutagenicity and estrogenicity of BPF and BPS ([http://onlinelibrary.wiley.com/doi/10.1002/tox.10035/abstract Chen et al. (2001)] and [http://toxsci.oxfordjournals.org/content/84/2/249 Kitamura et al. (2005)]) indicate their potential harmfulness but further research is needed to fully assess their impact on human health.

E. coli KRX carrying genes for the bisdA | bisdB fusion protein behind the medium strong constitutive promoter <partinfo>J23110</partinfo> with RBS <partinfo>B0034</partinfo> was cultivated at 30 °C for 36 h with LB-Medium containing 120 mg L-1 BPA, BPF respectively BPS. The BPF and BPS concentration were determined with a HPLC using the same method as with BPA. Figure 8 shows the degradation of the respective bisphenol after 24 h of cultivation in percent.

The results of the experiment indicate that the bisdA | bisdB fusion protein has a high specificity for the degradation of BPA. In addition it is possible that the decrease in BPF and BPS concentration is due to internalization of those bisphenols or a endogenous enzyme of E. coli KRX and that the bisdA | bisdB fusion protein was not responsible. It can be assumed that false positive signals because of BPF or BPS present in a sample are unlikely.

BPA degradation with constructs containing FNR

Constructs containing FNR, BisdA and BisdB polycistronic <partinfo>K525551</partinfo>, FNR and a fusion protein of BisdA and BisdB <partinfo>K525582</partinfo> and a fusion protein of FNR, BisdA and BisdB <partinfo>K525560</partinfo> were tested for their ability to degrade BPA. Cultivations were done using the same conditions as with previous constructs. The results are shown in Figure 9 below.

The results indicate that the BPA degradation was improved using fusion proteins compared to the completely polycistronic construct. Also the fusion protein of all three enzymes (<partinfo>K525560</partinfo>) involved in the degradation of BPA worked as intended which is quite impressive.

Comparison of all constructs used for BPA degradation

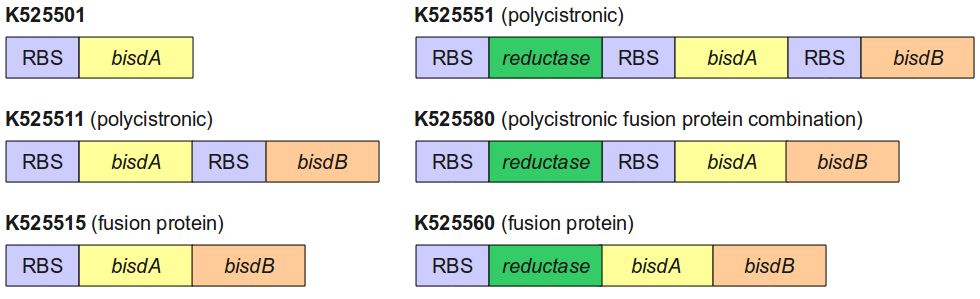

Figure 10 gives an overview of the constructs employed for the degradation of BPA.

All constructs were cultivated under the same conditions as described under Cultivations. BPA concentrations were measured using HPLC. Figure 11 shows the percentage of BPA degraded in 24 h of cultivation and the specific BPA degradation rate calculated with the regular model and in the case of <partinfo>K525560</partinfo> with the model for the fusion protein between FNR, BisdA and BisdB.

We are especially impressed that the fusion protein of FNR, BisdA and BisdB (<partinfo>K525560</partinfo>) not only was capable to degrade BPA but also was the fastest construct we employed. This also contributes to the feasibility of our approach for a cell free BPA biosensor since in a cell free environment fusion proteins are beneficial when compared to their non-fused counterparts.

Modeling of intracellular bisphenol A degradation

Regular model

The modeling was done with the software [http://www.berkeleymadonna.com/ Berkeley Madonna] using the [http://en.wikipedia.org/wiki/Runge–Kutta_methods#Common_fourth-order_Runge.E2.80.93Kutta_method common fourth-order Runge-Kutta] method to solve the equations. The model was fitted to the measured data shown above by the function "curve fit" in Berkeley Madonna to calculate the parameters, constants, etc..

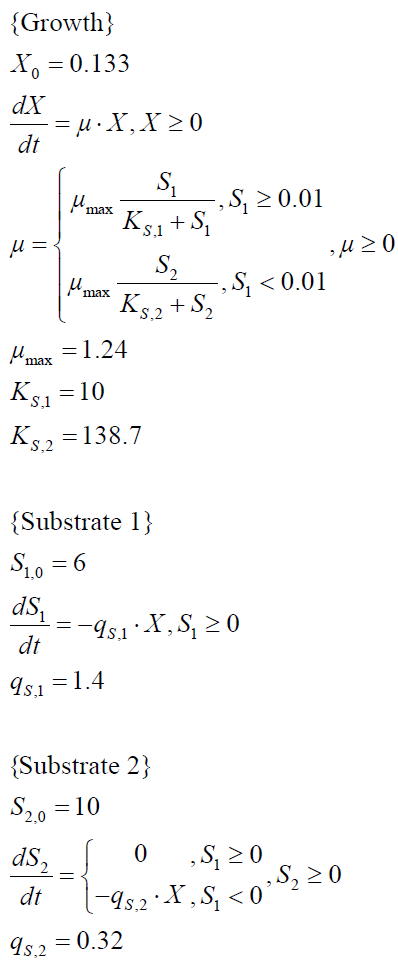

To model the BPA degradation by E. coli carrying BioBricks for BPA degradation (<partinfo>K123000</partinfo> and <partinfo>K123001</partinfo>), first the cell growth has to be described to calculate a specific BPA degradation rate per cell. The observed growth of E. coli on (our) LB medium was [http://en.wikipedia.org/wiki/Diauxie diauxic] with two different growth phases. Cell growth is a [http://en.wikipedia.org/wiki/First_order_kinetics#First-order_reactions first-order reaction] and is mathematically described as

with the specific growth rate µ and the cell count X. The specific growth rate is dependent on the concentration of the growth limiting substrate (e.g. glucose) and can be described as

with the substrate concentration S, the Monod constant KS and the maximal specific growth rate µmax ([http://www.annualreviews.org/doi/abs/10.1146/annurev.mi.03.100149.002103 Monod, 1949]). Because LB medium is a complex medium we cannot measure the substrate concentration so we have to assume an imaginary substrate concentration. Due to the diauxic growth two different substrates with different Monod constants and consumption rates are necessary to model the cell growth. The amount of a substrate S can be modeled as follows

with the specific substrate consumption rate per cell qS. The whole model for the diauxic growth of E. coli on LB medium with two not measurable (imaginary) substrates looks like:

The specific BPA degradation rate per cell qD is modeled with an equation like eq. (3). In the beginning of the cultivations, when E. coli growths on the "good" imaginary substrate S1, no BPA degradation is observed. When this substrate is consumed, the BPA degradation starts. The model for this diauxic behavior is as follows:

Figures 9 - 12 show a comparison between modeled and measured data for cultivations with BPA degrading E. coli. In Table 1 the parameters for the model are given, obtained by curve fitting the model to the data.

Model for the fusion protein between FNR, BisdA and BisdB

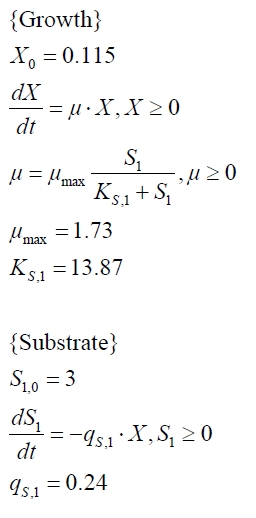

The cultivations and BPA degradation of E. coli KRX carrying a fusion protein consisting of ferredoxin-NADP+ oxidoreductase, ferredoxinbisd and cytochrome P450bisd differ from the cultivations with the other BPA degrading BioBricks. Thus, the model for these cultivations has to be adjusted to this behaviour. First of all, no diauxic growth is observed so the growth can be modeled more easily like

The BPA degradation starts when the imaginary substrate is depleted, like observed in the other cultivations with BPA degrading BioBricks. But it seems that the BPA degradation is getting slower with longer cultivation time. So it is modeled with a Monod-like term in which the specific BPA degradation rate is dependent from the BPA concentration:

with the maximal specific BPA degradation rate qD,max and the constant KD.

Figures 13 shows a comparison between modeled and measured data for cultivations with BPA degrading fusion protein E. coli. In Tab. 1 the parameters for the model are given, obtained by curve fitting the model to the data.

Comparison between modeled and measured data

Tab. 1: Parameters of the model.

| Parameter | <partinfo>K525512</partinfo> | <partinfo>K525517</partinfo> | <partinfo>K525552</partinfo> | <partinfo>K525562</partinfo> | <partinfo>K525582</partinfo> |

|---|---|---|---|---|---|

| X0 | 0.112 108 mL-1 | 0.138 108 mL-1 | 0.109 108 mL-1 | 0.115 108 mL-1 | 0.139 108 mL-1 |

| µmax | 1.253 h-1 | 1.357 h-1 | 0.963 h-1 | 1.730 h-1 | 0.858 h-1 |

| KS,1 | 2.646 AU-1 | 1.92 AU-1 | 5.35 AU-1 | 13.87 AU-1 | 3.05 AU-1 |

| KS,2 | 265.1 AU-1 | 103.1 AU-1 | 82.6 AU-1 | - | 32.5 AU-1 |

| S1,0 | 1.688 AU | 1.166 AU | 4.679 AU | 3.003 AU | 2.838 AU |

| qS,1 | 0.478 AU 10-8 cell-1 | 0.319 AU 10-8 cell-1 | 0.883 AU 10-8 cell-1 | 0.240 AU 10-8 cell-1 | 0.544 AU 10-8 cell-1 |

| S2,0 | 16.091 AU | 6.574 AU | 3.873 AU | - | 2.402 AU |

| qS,2 | 0.295 AU 10-8 cell-1 | 0.191 AU 10-8 cell-1 | 0.082 AU 10-8 cell-1 | - | 0.056 AU 10-8 cell-1 |

| BPA0 | 0.53 mM | 0.53 mM | 0.41 mM | 0.45 mM | 0.53 mM |

| qD | 8.76 10-11 mM cell-1 | 1.29 10-10 mM cell-1 | 5.67 10-11 mM cell-1 | - | 1.13 10-10 mM cell-1 |

| qD,max | - | - | - | 1.32 10-10 mM cell-1 | - |

| KD | - | - | - | 0.121 mM-1 | - |

The specific BPA degradation rate per cell qD is about 50 % higher when using the fusion protein compared to the polycistronic bisdAB gene. On average, this results in a 9 hours faster, complete BPA degradation by E. coli carrying <partinfo>K525517</partinfo> compared to <partinfo>K525512</partinfo> as observed during our cultivations. The fusion protein between BisdA and BisdB improves the BPA degradation by E. coli. Introducing a polycistronic ferredoxin-NADP+ reductase gene into these systems does not lead to a higher specific BPA degradation rate. The rates are a bit lower, though. The effect that the BisdA | BisdB fusion protein is more efficient than BisdB when expressed polycistronically with BisdA can still be observed in this setup. The cultivations with the expression of the fusion protein FNR | BisdA | BisdB differ from the expression of the other BPA degrading BioBricks. The BPA degradation rate is concentration dependent which is typical for enzymatic reactions but was not observed in the other cultivations. In addition, the growth was faster and not diauxic. The maximal specific BPA degradation rate of this BioBrick is higher than the observed specific BPA degradation rates in the other cultivations. But due to the dependence of the BPA degradation on the BPA concentration, the BPA degradation with this BioBrick is not as efficient and not complete. Anyway, the fact that this BioBrick is working is impressive.

Interpretation of the results

Misfolding seems to be a problem when expressing BisdA and BisdB in E. coli. To reduce this, the cultivation conditions were improved for the BPA degradation with the polycistronic bisdAB gene in E. coli first, compared to the literature ([http://onlinelibrary.wiley.com/doi/10.1111/j.1365-2672.2008.03843.x/full Sasaki et al., 2008]). Problems with misfolding of BisdA and BisdB could be reduced by lowering the temperature as well as growth rate and by using a weaker promoter for expression.

When degrading BPA with E. coli using the BisdA | BisdB fusion protein, both domains (BisdA and BisdB) are active and correctly folded because otherwise there would be no BPA degradation measured and no BPA degradation products 1,2-Bis(4-hydroxyphenyl)-2-propanol and 2,2-Bis(4-hydroxyphenyl)-1-propanol would be detectable, which could definetely be identified via MS-MS. The about 50 % higher specific BPA degradation rate in E. coli expressing the BisdA | BisdB fusion protein could be explained either by improved folding properties of the fusion protein or by the closer distance of BisdA and BisdB in the fusion protein leading to a faster electron transfer and therefore a more efficient reaction. In this case, which has to be further analysed by cell-free enzyme assays, a natural cytochrome P450 class I electron transport system was converted into a more effective class V electron transport system, demonstrating the new possibilities of synthetic biology. In addition, this new class V system would work without alanine-rich linker, potentially changing the view on cytochrome P450 depending electron transport chains.

Summary of results

Tab. 2: Important parameters of <partinfo>K525512</partinfo>, <partinfo>K525517</partinfo>, <partinfo>K525552</partinfo>, <partinfo>K525562</partinfo> and <partinfo>K525582</partinfo>.

| Experiment | Characteristic | Result <partinfo>K525517</partinfo> | Result <partinfo>K525512</partinfo> | Result <partinfo>K525552</partinfo> | Result <partinfo>K525562</partinfo> | Result <partinfo>K525582</partinfo> |

|---|---|---|---|---|---|---|

| Expression in E. coli | Compatibility | E. coli KRX, TOP10, MACH1, BL21(DE3) | ||||

| Expression | Constitutive | |||||

| Optimal temperature | 30 °C | |||||

| BPA working concentration | 120 mg L-1 (0.53 mM) | |||||

| Purification | Molecular weight | 59.3 kDa | 11.2 and 48.3 kDa | 28.0, 11.2 and 48.3 kDa | 87.1 kDa | 28.0 and 59.3 kDa |

| Theoretical pI | 4.99 | 4.31 and 5.27 | 6.17, 4.31 and 5.27 | 5.26 | 6.17 and 4.99 | |

| High absorbtion | 450 nm (due to CYP) | |||||

| Degradation of BPA | Completely degradation of 0.53 mM BPA | 21 - 24 h | 30 - 33 h | > 36 h | > 36 h | 30 - 33 h |

| Specific BPA degradation rate | 1.29 10-10 mM cell-1 | 8.76 10-11 mM cell-1 | 5.67 10-11 mM cell-1 | 1.32 10-10 mM cell-1 * | 1.13 10-10 mM cell-1 | |

* Different model: the maximal specific BPA degradation rate was calculated.

References

Monod J (1949) The growth of bacterial cultures, [http://www.annualreviews.org/doi/abs/10.1146/annurev.mi.03.100149.002103 Annu Rev Microbiol 3:371-394].

Sasaki M, Maki J, Oshiman K, Matsumura Y, Tsuchido T (2005) Biodegradation of bisphenol A by cells and cell lysate from Sphingomonas sp. strain AO1, [http://www.springerlink.com/content/q7864l02734wg32m/ Biodegradation 16(5):449-459].

Sasaki M, Tsuchido T, Matsumura Y (2008) Molecular cloning and characterization of cytochrome P450 and ferredoxin genes involved in bisphenol A degradation in Sphingomonas bisphenolicum strain AO1, [http://onlinelibrary.wiley.com/doi/10.1111/j.1365-2672.2008.03843.x/full J Appl Microbiol 105(4):1158-1169].

"

"