Team:Bielefeld-Germany/Results/S-Layer/Guide/3b

From 2011.igem.org

m |

|||

| Line 10: | Line 10: | ||

The advantage of a bioreactor over shaking flasks is the possibility to control cultivation parameters like temperature, pH or dissolved oxygen (DO). When cultivating ''E. coli'' in shaking flasks the cells are often growing oxygen limited because of a oxygen transmission rate (normally k<sub>L</sub>a = 40 - 80 h<sup>-1</sup> in shaking flasks but up to 600 h<sup>-1</sup> in a bioreactor). The production of acetate and lactate leeds to a pH shift in a shaking flask. In a bioreactor pH and DO is steady during the whole cultivation leeding to higher growth rates and yields of biomass. | The advantage of a bioreactor over shaking flasks is the possibility to control cultivation parameters like temperature, pH or dissolved oxygen (DO). When cultivating ''E. coli'' in shaking flasks the cells are often growing oxygen limited because of a oxygen transmission rate (normally k<sub>L</sub>a = 40 - 80 h<sup>-1</sup> in shaking flasks but up to 600 h<sup>-1</sup> in a bioreactor). The production of acetate and lactate leeds to a pH shift in a shaking flask. In a bioreactor pH and DO is steady during the whole cultivation leeding to higher growth rates and yields of biomass. | ||

| - | For our cultivations we used a [http://www.bioengineering-inc.com/standard-reactors.php?id=2.1 Bioengineering NLF22 7 L] with Bioengineering DCU. We implemented a sequencer which automatically pumped an inducer solution after 4 h cultivation time to start protein expression. Other parameters were: | + | For our cultivations we used a [http://www.bioengineering-inc.com/standard-reactors.php?id=2.1 Bioengineering NLF22 7 L] or a [http://www.gmi-inc.com/BioEngineering-KLF-Small-Laboratory-Fermenter.html#product_desc Bioengineering KLF] with Bioengineering DCU and software. We implemented a sequencer which automatically pumped an inducer solution after 4 h cultivation time to start protein expression. Other parameters were: |

* Medium: [[Team:Bielefeld-Germany/Protocols/Materials#HSG_medium | HSG medium]] with 20 mg L<sup>-1</sup> chloramphenicol or 100 mg L<sup>-1</sup> ampicillin | * Medium: [[Team:Bielefeld-Germany/Protocols/Materials#HSG_medium | HSG medium]] with 20 mg L<sup>-1</sup> chloramphenicol or 100 mg L<sup>-1</sup> ampicillin | ||

| - | * Culture volume: | + | * Culture volume: 2.5 - 5 L |

| - | * Starting OD<sub>600</sub>: 0. | + | * Starting OD<sub>600</sub>: 0.1 - 0.4 |

| - | * DO: | + | * DO: 60 % airsaturation (controlled with stirrer cascade starting with 200 rpm) |

* pH: 7.0 (controlled with 20 % phosphoric acid and 2 M NaOH) | * pH: 7.0 (controlled with 20 % phosphoric acid and 2 M NaOH) | ||

* Antifoam: BASF pluronic XXX | * Antifoam: BASF pluronic XXX | ||

| + | * Induction solution: 0.2 % L-rhamnose and 1 mM IPTG | ||

The use of the autoinduction sequencer enables a cultivation over night. The next morning the cells have to be harvested by centrifugation. | The use of the autoinduction sequencer enables a cultivation over night. The next morning the cells have to be harvested by centrifugation. | ||

| Line 24: | Line 25: | ||

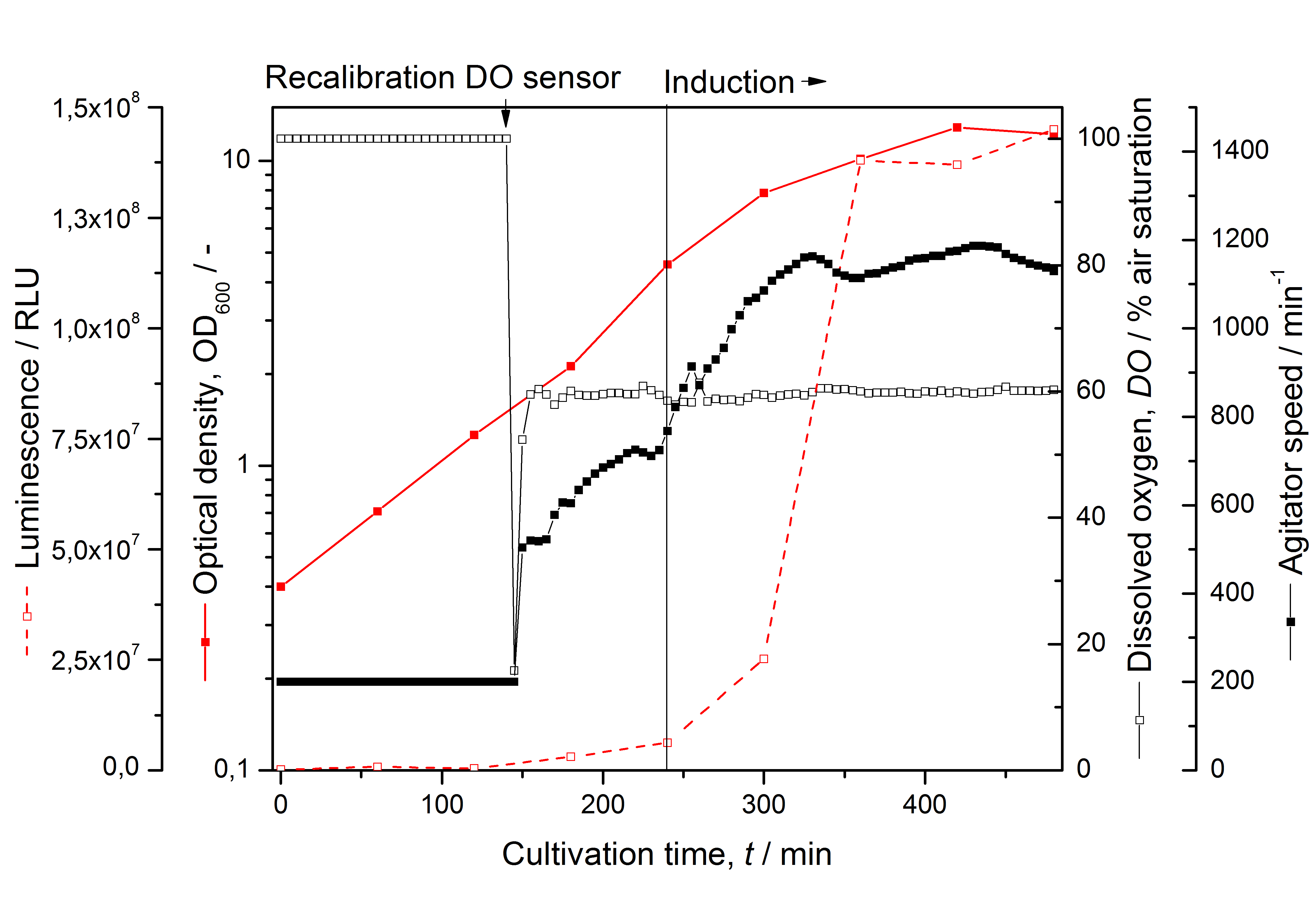

| - | + | The following figure shows the expression of an SgsE | luciferase S-layer fusion protein <partinfo>K525311</partinfo> in ''E. coli'' KRX in HSG medium with autoinduction sequencer as described above. Optical density, activity of the fused luciferase, dissolved oxygen and agitator speed are plotted against the cultivation time. | |

| + | |||

| + | [[Image:IGEM-Bielefeld2011-Cultivation311.jpg|500px|thumb|center|'''Fig. 1: Bioreactor cultivation of ''E. coli'' KRX expressing the fusion protein SgsE | luciferase <partinfo>K525311</partinfo> under the control of a T7 / lac promoter. Induction with 1 mM IPTG and 0.2 % L-rhamnose after 4 h controlled by sequencer. Cultivation in [http://www.gmi-inc.com/BioEngineering-KLF-Small-Laboratory-Fermenter.html#product_desc Bioengineering KLF] bioreactor with 2.5 L [[Team:Bielefeld-Germany/Protocols/Materials#HSG_medium | HSG medium]] with 20 mg L<sup>-1</sup> chloramphenicol starting with OD<sub>600</sub> = 0.4. Dissolved oxygen was regulated to 60 % airsaturation (controlled with stirrer cascade starting with 200 rpm) and the pH to 7.0 (controlled with 20 % phosphoric acid and 2 M NaOH). The dissolved oxygen sensor had to be recalibrated after about 140 min. ''']] | ||

Revision as of 11:50, 28 October 2011

Expression of S-layer protein under control of T7 promoter in a bioreactor

The expression of S-layer proteins is stressful for Escherichia coli. So using E. coli KRX to express genes under the control of a T7 promoter is an easy way to overexpress your proteins and seperate growth and production phase. This strain carries a T7 polymerase gene under the control of a rhamnose promoter in its genome and it is also optimized for cloning so you do not have to transform your plasmids after assembly in e.g. TOP10, isolate them and bring them in an expression strain like BL21(DE3) - you can go with a single transformation step from assembly to production.

The advantage of a bioreactor over shaking flasks is the possibility to control cultivation parameters like temperature, pH or dissolved oxygen (DO). When cultivating E. coli in shaking flasks the cells are often growing oxygen limited because of a oxygen transmission rate (normally kLa = 40 - 80 h-1 in shaking flasks but up to 600 h-1 in a bioreactor). The production of acetate and lactate leeds to a pH shift in a shaking flask. In a bioreactor pH and DO is steady during the whole cultivation leeding to higher growth rates and yields of biomass.

For our cultivations we used a Bioengineering NLF22 7 L or a Bioengineering KLF with Bioengineering DCU and software. We implemented a sequencer which automatically pumped an inducer solution after 4 h cultivation time to start protein expression. Other parameters were:

- Medium: HSG medium with 20 mg L-1 chloramphenicol or 100 mg L-1 ampicillin

- Culture volume: 2.5 - 5 L

- Starting OD600: 0.1 - 0.4

- DO: 60 % airsaturation (controlled with stirrer cascade starting with 200 rpm)

- pH: 7.0 (controlled with 20 % phosphoric acid and 2 M NaOH)

- Antifoam: BASF pluronic XXX

- Induction solution: 0.2 % L-rhamnose and 1 mM IPTG

The use of the autoinduction sequencer enables a cultivation over night. The next morning the cells have to be harvested by centrifugation.

Now you have a lot of biomass which you have to disrupt - learn more about it!

The following figure shows the expression of an SgsE | luciferase S-layer fusion protein <partinfo>K525311</partinfo> in E. coli KRX in HSG medium with autoinduction sequencer as described above. Optical density, activity of the fused luciferase, dissolved oxygen and agitator speed are plotted against the cultivation time.

"

"