Team:Bielefeld-Germany/Protocols

From 2011.igem.org

Transformation via electroporation

- Thaw 50 µL competent E.coli cells on ice, dilute with icecold 50 µL glycerol (10 %) if necessary

- Add 0.5-5 µL plasmid to 50 µl electrocompetent cells

- Store cells on ice for 1 minute

- Electroporate at U = 2.5 kV, C = 25 µF, R = 400 Ώ

- Transfer transformation reaction to 450 µL SOC-Medium and shake 1 h at 37 °C

- Centrifuge 2 min at 800 rpm and plate on selective LB-Medium

Transformation of Single Step (KRX) Competent Cells by Promega

using [http://www.promega.com/~/media/Files/Resources/Protocols/Technical%20Bulletins/101/Single%20Step%20Competent%20Cells%20Protocol.ashx protocol for E. coli KRX single step competent cells by Promega]

- Remove Single Step (KRX) Competent Cells from –70 °C, and place on ice for 5 minutes or until just thawed.

- Add 1–50 ng of DNA (in a volume not greater than 5 μL) to the Single Step (KRX) Competent Cells. Move the pipette tip through the cells while dispensing. Quickly flick the tube several times. Do not vortex!

- Immediately return the tubes to ice for 5–30 minutes

- Heat-shock cells for 15–20 seconds in a water bath at exactly 42 °C. Do not shake.

- Immediately place the tubes on ice for 2 minutes.

- Add 450 μL of room-temperature SOC medium to each transformation reaction, and incubate for 60 minutes at 37 °C with shaking (approximately 225 rpm). For best transformation efficiency, lay the tubes on their sides and tape them to the platform.

- For each transformation reaction, we recommend plating 100 μL of undiluted cells and 1:10 and 1:100 cell dilutions on antibiotic plates. Incubate the plates at 37 °C overnight.

Standard BioBrick Assembly

modified from [http://openwetware.org/wiki/Silver:_BB_Strategy Silver lab]:

This assembly method can be used for BioBricks which are bigger than 150 bp. The BioBrick should be at least 500 bp bigger or smaller than the backbone. The BioBrick, which complies with these conditions, is used as the insert and is assembled into the prefix or suffix of the other used BioBrick, called vector. So you have to differentiate between a prefix and a suffix insertion.

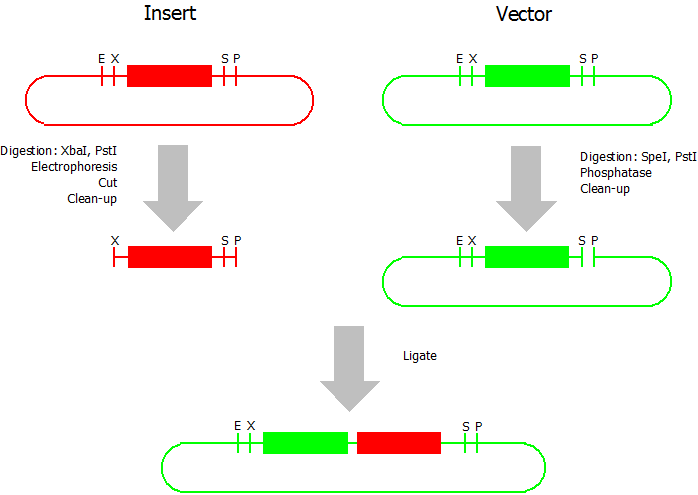

Suffix Insertion

- Digestion of insert: at least 700 ng DNA / 10 µL volume, 1 µL 10x Tango buffer, 0.5 µL XbaI, 1 µL PstI. Digest for 2 h at 37 °C, afterwards inactivation for 20 min at 80 °C. Clean up the insert via gel electrophoresis. When cutting the insert out of the gel try to avoid staining or exposure to ultraviolet light of the insert.

- Digestion of vector about 700 ng DNA / 10 µL volume, 1 µL 10x orange buffer, 0.5 µL SpeI, 0.5 µL PstI. Digest for 2 h at 37 °C, afterwards inactivation for 20 min at 80 °C. Add 1 µL SAP (shrimp alcaline phosphatase) and 1.2 µL 10 x SAP buffer, incubate for 1 h at 37 °C. Clean up the vector with a PCR clean-up kit.

- Ligation: after digestion and clean-up: 50 - 200 ng of vector, 3 - 10 fold molar access of insert, 20 µL ligation volume, 2 µL T4-Ligase-Buffer, 1 µL T4-Ligase. Incubate for 20 - 30 min at room temperature, afterwards inactivation for 5 min at 70 °C. Then: store at -20 °C or transform.

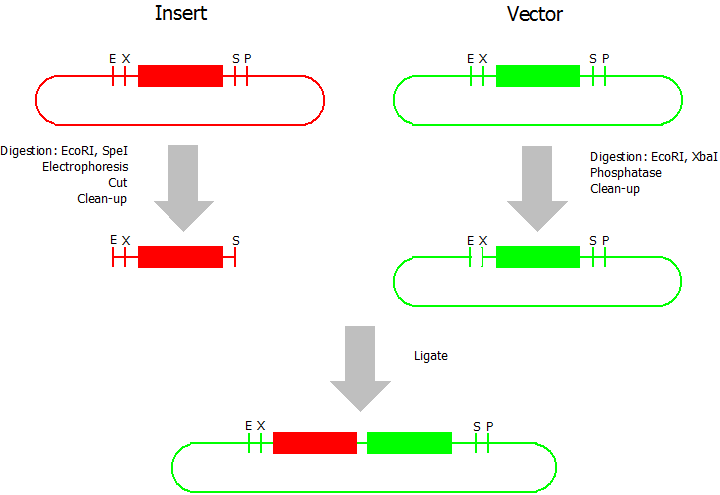

Prefix Insertion

- Digestion of insert: at least 700 ng DNA / 10 µL volume, 1 µL 10x BamHI buffer, 0.5 µL EcoRI, 0.5 µL SpeI. Digest for 2 h at 37 °C, afterwards inactivation for 20 min at 80 °C. Clean up the insert via gel electrophoresis. When cutting the insert out of the gel try to avoid staining or exposure to ultraviolet light of the insert.

- Digestion of vector about 700 ng DNA / 10 µL volume, 1 µL 10 x Tango buffer, 0.5 µL EcoRI, 0.5 µL XbaI. Digest for 2h at 37 °C, afterwards inactivation for 20 min at 80 °C. Add 1 µL SAP (shrimp alcaline phosphatase) and 1.2 µL 10 x SAP buffer, incubate for 1 h at 37 °C. Clean up the vector with a PCR clean-up kit.

- Ligation: after digestion and clean-up: 50 - 200 ng of vector, 3 - 10 fold molar access of insert, 20 µL ligation volume, 2 µL T4-Ligase-Buffer, 1 µL T4-Ligase. Incubate for 20 - 30 min at room temperature, afterwards inactivation for 5 min at 70 °C. Then: store at -20 °C or transform.

Variations

- A digestion over night is possible. If you digest over night use only 0.1 µL restriction enzyme.

- It is also possible to use PCR product as insert. Digest after PCR with corresponding restriction enzymes and clean up with PCR clean-up kit. This could lead to higher yields of insert DNA because a lot of DNA gets lost during the gel electrophoresis clean up.

- Sometimes some BioBricks are hard to assemble. Then you have to clean up the vector by gel electrophoresis as well.

Standard Freiburg BioBrick Assembly

Modified from [http://openwetware.org/wiki/Silver:_BB_Strategy Silver lab] and [http://partsregistry.org/Assembly_standard_25 Assembly standard 25]:

This assembly method can be used for fusion protein assemblies with BioBricks which are bigger than 150 bp. The BioBrick should be at least 500 bp bigger or smaller than the backbone. The BioBrick, which complies with these conditions, is used as the insert and is assembled into the prefix or suffix of the other used BioBrick, which is called vector and needs to be available in the BioBrick [http://partsregistry.org/Assembly_standard_25 Assembly standard 25]. You have to differentiate between a prefix and a suffix insertion.

Suffix Insertion

- Digestion of insert: at least 700 ng DNA / 10 µL volume, 1 µL 10x NEB buffer 4 + 0.1 µL 100x BSA, 0.5 µL NgoMIV (NEB), 1 µL PstI. Digest for 2 h at 37 °C, afterwards inactivation for 20 min at 80 °C. Clean up the insert via gel electrophoresis. When cutting the insert out of the gel try to avoid staining or exposure to ultraviolet light of the insert.

- Digestion of vector about 700 ng DNA / 10 µL volume, 1 µL 10x orange buffer, 0.5 µL AgeI, 0.5 µL PstI. Digest for 2 h at 37 °C, afterwards inactivation for 20 min at 80 °C. Add 1 µL SAP (shrimp alcaline phosphatase) and 1.2 µL 10x SAP buffer, incubate for 1 h at 37 °C. Clean up the vector with a PCR clean-up kit.

- Ligation: after digestion and clean-up: 50 - 200 ng of vector, 3 - 10 fold molar access of insert, 20 µL ligation volume, 2 µL T4-Ligase-Buffer, 1 µL T4-Ligase. Incubate for 20 - 30 min at room temperature, afterwards inactivation for 5 min at 70 °C. Then: store at -20 °C or transform.

Prefix Insertion

- Digestion of insert: at least 700 ng DNA / 10 µL volume, 1 µL 10x orange buffer, 0.5 µL EcoRI, 0.5 µL AgeI. Digest for 2 h at 37 °C, afterwards inactivation for 20 min at 80 °C. Clean up the insert via gel electrophoresis. When cutting the insert out of the gel try to avoid staining or exposure to ultraviolet light of the insert.

- Digestion of vector about 700 ng DNA / 10 µL volume, 1 µL 10 x NEB buffer 4, 0.5 µL EcoRI, 0.5 µL NgoMIV (NEB). Digest for 2h at 37 °C, afterwards inactivation for 20 min at 80 °C. Add 1 µL SAP (shrimp alcaline phosphatase) and 1.2 µL 10 x SAP buffer, incubate for 1 h at 37 °C. Clean up the vector with a PCR clean-up kit.

- Ligation: after digestion and clean-up: 50 - 200 ng of vector, 3 - 10 fold molar access of insert, 20 µL ligation volume, 2 µL T4-Ligase-Buffer, 1 µL T4-Ligase. Incubate for 20 - 30 min at room temperature, afterwards inactivation for 5 min at 70 °C. Then: store at -20 °C or transform.

Variations

- A digestion over night is possible. If you digest over night use only 0.1 µL restriction enzyme.

- It is also possible to use PCR product as insert. Digest after PCR with corresponding restriction enzymes and clean up with PCR clean-up kit. This could lead to higher yields of insert DNA because a lot of DNA gets lost during the gel electrophoresis clean up.

- Sometimes some BioBricks are hard to assemble. Then you have to clean up the vector by gel electrophoresis as well.

Standard 3A assembly

Modified from [http://ginkgobioworks.com/support/BioBrick_Assembly_Manual.pdf BioBrick Assembly Manual by Ginkgo BioWorks]

Digestion

- Thaw DNA from upstream and downstream part and the destination plasmid on ice.

- Destination plasmid has to carry the ccdB gene <partinfo>P1010</partinfo> as insert and has to have a different antibiotic resistance than the plasmids carrying the upstream and downstream parts

- DNA has to be cleaned (by MiniPrep or after a PCR)

- 500 ng DNA / digestion mix for upstream part, downstream part and destination plasmid (total volume of mix 10 µL, dilute with ddH20 if necessary)

- Add 1 µL of 10x buffer and restriction enzymes as shown in the following table:

| Upstream part | Downstream part | Destination plasmid | |

|---|---|---|---|

| enzyme 1 | 0.5 µL EcoRI | 0.5 µL XbaI | 0.5 µL EcoRI |

| enzyme 2 | 0.5 µL SpeI | 1 µL PstI | 0.5 µL PstI |

| buffer | BamHI | Tango | Orange |

- Incubation of the digestion mixes at 37 °C

- After 2 h: add 0.5 µL SAP (shrimp alcaline phosphatase) and 1.15 µL 10x SAP buffer to destination plasmid mix, continue incubation at 37 °C

- After another hour: heat inactivation of all mixes for 20 min at 80 °C

- Continue with ligation or freeze the mixes

Ligation

- Ligation mix:

- 2 µL ddH2O

- 5 µL of every digestion mix (so 15 µL in total)

- 2 µL T4-DNA-ligase buffer (thaw on ice!)

- 1 µL T4-DNA-ligase

- Incubate at least 20 min at room temperature, afterwards heat inactivation for 5 min at 70 °C (optional)

- Freeze ligation mix or continue with transformation (heatshock or electroporation)

Freiburg 3A assembly

Modified from [http://ginkgobioworks.com/support/BioBrick_Assembly_Manual.pdf BioBrick Assembly Manual by Ginkgo BioWorks] and [http://partsregistry.org/Assembly_standard_25 Assembly standard 25]

Digestion

- Thaw DNA from upstream and downstream part (=N-terminal and C-terminal protein domain) and the destination plasmid on ice.

- Destination plasmid has to carry the ccdB gene <partinfo>P1010</partinfo> as insert and has to have a different antibiotic resistance than the plasmids carrying the upstream and downstream parts

- DNA has to be cleaned (by MiniPrep or after a PCR)

- 500 ng DNA / digestion mix for upstream part, downstream part and destination plasmid (total volume of mix 10 µL, dilute with ddH20 if necessary)

- Add 1 µL of 10x buffer and restriction enzymes as shown in the following table:

| Upstream part | Downstream part | Destination plasmid | |

|---|---|---|---|

| enzyme 1 | 0.5 µL EcoRI | 0.5 µL NgoMIV | 0.5 µL EcoRI |

| enzyme 2 | 0.5 µL AgeI | 1 µL PstI | 0.5 µL PstI |

| buffer | Orange | NEB buffer 4 + BSA | Orange |

- Incubation of the digestion mixes at 37 °C

- After 2 h: add 0.5 µL SAP (shrimp alcaline phosphatase) and 1.15 µL 10x SAP buffer to destination plasmid mix, continue incubation at 37 °C

- After another hour: heat inactivation of all mixes for 20 min at 80 °C

- Continue with ligation or freeze the mixes

Ligation

- Ligation mix:

- 2 µL ddH2O

- 5 µL of every digestion mix (so 15 µL in total)

- 2 µL T4-DNA-ligase buffer (thaw on ice!)

- 1 µL T4-DNA-ligase

- Incubate at least 20 min at room temperature, afterwards heat inactivation for 5 min at 70 °C (optional)

- Freeze ligation mix or continue with transformation (heatshock or electroporation)

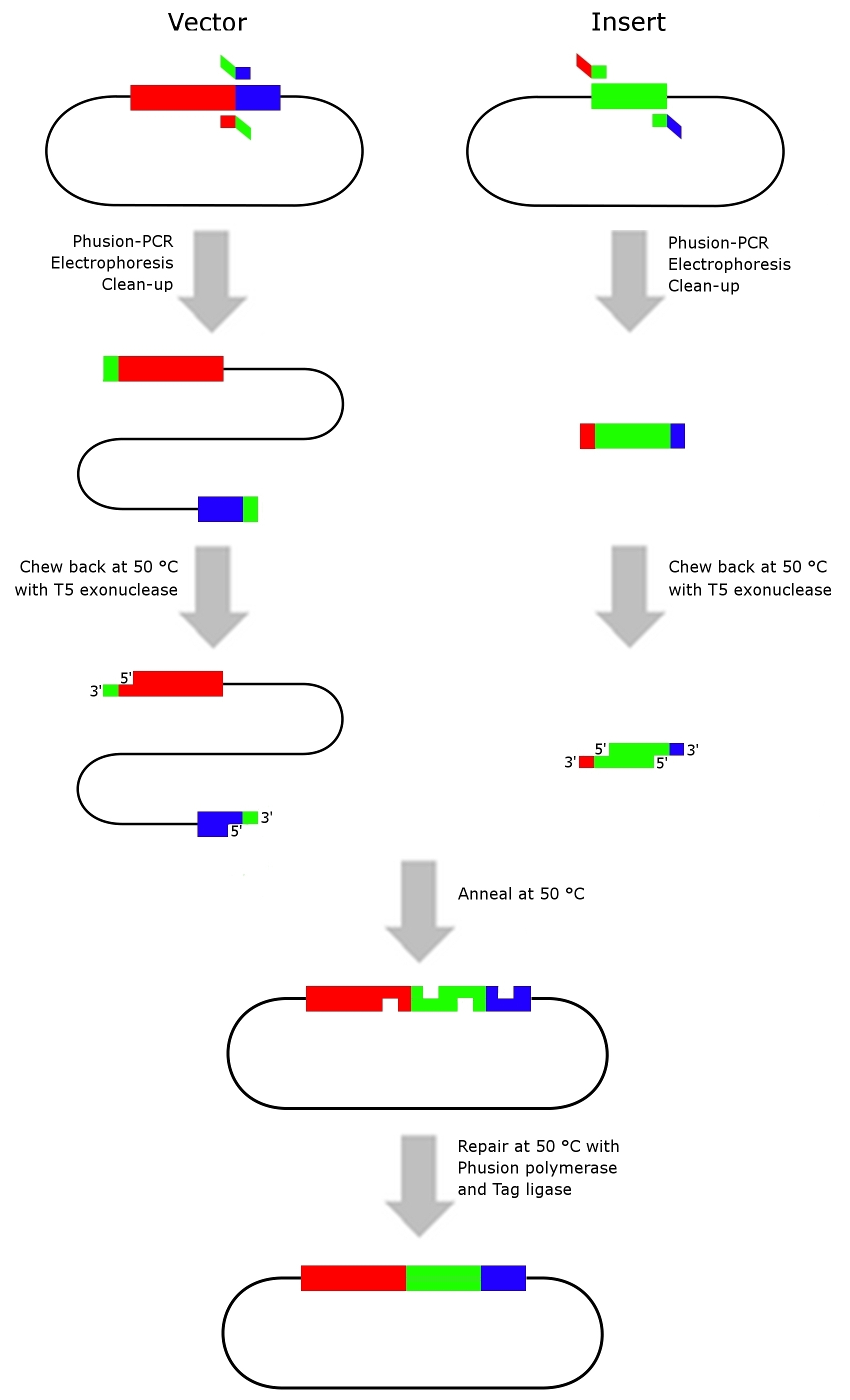

Gibson assembly

Modified from [http://www.nature.com/nmeth/journal/v6/n5/full/nmeth.1318.html Gibson et al. (2009)]

This assembly method is an isothermal, single-reaction method for assembling multiple overlapping DNA molecules. By coordinating the activity of a 5‘ exonuclease, a DNA polymerase and a DNA ligase two adjacent DNA fragments with complementary terminal sequence overlaps can be joined into a covalently sealed molecule, without the use of any restriction endonuclease.

Preparation of DNA molecules for in vitro recombination

- Generate the complementary sequence overlaps by PCR using the Phusion DNA-polymerase. If necessary add 5 M Betain in the reaction mix by reducing the amount of H2O to decrease the number of false PCR products.

- Identify the PCR products of interest by gel electrophoresis with known DNA standards.

- Extract the PCR products from the gel by cutting out the DNA fragments and clean them up by using a commercial clean up kit.

In vitro recombination

- assembly mixture (6 mL):

- 320 µL 5x isothermal reaction buffer

- 0.64 µL of 10 U mL-1 T5 exonuclease (for DNA molecules overlapping by greater than 150 bp add 3.2 µL of 10 U ml–1 T5 exonuclease)

- 20 µL of 2 U mL-1 Phusion DNA polymerase

- 160 µL of 40 U mL-1 taq DNA ligase

- add ddH2O water up to a final volume of 1.2 mL

- aliquote 15 µL of the reagent-enzyme mix and store it at –20 ˚C

- Thaw 15 µL assembly mixture aliquot and keep it on ice until use.

- Add 5 µL of the purified DNA molecules in equimolar amounts (between 10 and 100 ng of each DNA fragment).

- Incubate the resulting mixture at 50 ˚C for 15 to 60 min, with 60 min being optimal.

- Transformation (heatshock or electroporation) without cleaning up the assembly product.

Restriction analysis

- Digest BioBrick of interest: about 400 ng DNA / 10 µL volume, 1 µL 10x orange buffer, 0.5 µL NotI or PstI. Digest for 2 h at 37 °C. NotI is used to determine the length of the BioBrick and the plasmid backbone, PstI ist used to determine the length of the BioBrick in the plasmid backbone.

- Gel electrophoresis: add 2 µL loading buffer to every digestion mix, apply about 100 - 200 ng DNA / pocket in gel. Don't forget to apply the uncut BioBrick as well. A good agarose concentration for BioBricks between 0.2 and 3 kb is 1.5 %. The smaller your BioBrick of interest is the higher the agarose concentration should be and vice versa. The gel electrophoresis is made with TAE-buffer. Be sure that you melt your agarose gel in the same buffer you use for the electrophoresis later.

Colony PCR

- Pick one colony with a sterile tip and elute it in 100 µL ddH20 or medium

- Store the colony in 4 °C while colony PCR is running

- One reaction mix contains:

- 10 µL 5x buffer

- 2 µL MgCl2 (25 mM stock)

- 1 µL dNTPs

- 0.5 µL primer mix (prefix/suffix primers or sequencing primers)

- 35.25 µL ddH2O

- 0.25 µL GoTaq polymerase (Promega)

- 1 µL template

- PCR program:

- Start: 3 min, 98 °C

- 30 cycles of:

- 30 s, 98 °C

- 30 s, 55 °C

- 30 s / 1 kb template, 72 °C

- Finish: 5 min, 72 °C

- Gel electrophoresis: check the fragment size

- Plate the correct colony

Cultivation

Expression of different S-layer genes in E. coli

- Used BioBricks: <partinfo>K525131</partinfo>, <partinfo>K525133</partinfo>, <partinfo>K525231</partinfo>, <partinfo>K525232</partinfo>, <partinfo>K525233</partinfo>, <partinfo>K525234</partinfo>, <partinfo>K525304</partinfo>, <partinfo>K525305</partinfo>, <partinfo>K525306</partinfo>, <partinfo>K525406</partinfo>, <partinfo>K525323</partinfo>

- Chassis: Promega's [http://www.promega.com/products/cloning-and-dna-markers/cloning-tools-and-competent-cells/bacterial-strains-and-competent-cells/single-step-_krx_-competent-cells/ E. coli KRX]

- Medium: LB medium supplemented with 20 mg L-1 Chloramphenicol or autoinduction medium

- Cultivations in LB-medium were supplemented with 0,1 % L-rhamnose as inducer, when the designated OD600 was reached.

- Autoinduction medium for expressing <partinfo>K525304</partinfo>, <partinfo>K525305</partinfo>, <partinfo>K525306</partinfo>, <partinfo>K525406</partinfo>, <partinfo>K525323</partinfo> was supplemented with 1 mM IPTG.

- For characterising the expression rate and the influance on E. coli growth behavior an automatic sampling system (Gilson fraction controller F2XX cooled (< 4 °C) with Julabo F10 water bath BU) was used. These cultivations were carried out in an Infors AG AQUATRON.

- 150 mL culture in 500 mL shaking flask with baffles (Schott) with silicon plugs

- Cultivation conditions: 37 °C at 120 rpm

Expression of bisphenol A degrading BioBricks in E. coli

- Used BioBricks: <partinfo>K525502</partinfo>, <partinfo>K525512</partinfo>, <partinfo>K525517</partinfo>, <partinfo>K525552</partinfo>

- Chassis: Promega's [http://www.promega.com/products/cloning-and-dna-markers/cloning-tools-and-competent-cells/bacterial-strains-and-competent-cells/single-step-_krx_-competent-cells/ E. coli KRX]

- Medium: LB medium supplemented with 100 mg L-1 Ampicillin and 120 mg L-1 bisphenol A

- BPA is thermally stable -> you can autoclave it together with the medium

- 100 mL culture in 300 mL shaking flask without baffles (Schott) with silicon plugs

- Cultivation temperature: 24 °C, 30 °C or 37 °C, tempered with Infors AG AQUATRON at 120 rpm

- for characterizations: automatic sampling every three hours with Gilson fraction controller F2XX cooled (< 4 °C) with Julabo F10 water bath BURMA-SHAVE!!

- the characterization experiment setup is shown on the picture on the right

Bioreactor cultivations with E. coli KRX

To obtain higher amounts and concentration of proteins we cultivated and expressed in a bioreactor. It is possible to cultivate several liters and to control temperature, pH and DO.

- Bioreactor: [http://www.bioengineering-inc.com/standard-reactors.php?id=2.1 Bioengineering NLF22 7 L] with Bioengineering DCU

- Medium: HSG medium supplemented with 20 mg L-1 chloramphenicol

- Culture volume: 4 L

- Starting OD600: 0.2

- DO: 40 % airsaturation (controlled with stirrer cascade starting with 200 rpm)

- pH: 7.0 (controlled with 20 % phosphoric acid and 2 M NaOH)

- Antifoam: BASF pluronic XXX

- Induction after 4 h cultivation time with 2 % rhamnose (in culture medium)

- Harvest after 13 h

Purification methods

Release of periplasmic protein fraction from E. coli by cold osmotic shock

Modified protocol from [http://www.jbc.org/content/240/9/3685.full.pdf+html?sid=4a90c176-0ec3-489f-8c82-4734274cebf5 Neu & Heppel, 1965].

- Centrifuge E. coli cell suspension for 5 min at 14000 g (4 °C) to collect the cells.

- Discard the entire supernatant.

- Resuspend the cells ice-cold cell fractionating buffer #1. The resulting volume should be 1/4 of the former suspension volume.

- Incubate for 20 min on ice. Ivert the suspension at regular intervals to counteract sedimentation.

- Centrifuge the cell suspension for 15 min at 14000 g (4 °C).

- Discard the entire supernatant.

- Resuspend the cells ice-cold cell fractionating buffer #2. The resulting volume should be 1/4 of the former suspension volume.

- Incubate for 10 min on ice under regular invertion.

- Centrifuge the cell suspension for 15 min at 14000 g (4 °C).

- Save the supernatant, which contains the periplasmatic proteins.

- If the periplasmatic protein fraction is turbid, re-centrifuge and filter it through a 0.2 µm filter.

Inclusion body clean-up

- harvest the cells by centrifugation (30 min, 10,000 g, 4 °C)

- resuspend pellet and disrupt cells

- centrifuge lysate (60 min, >17,000 g, 4 °C)

- wash pellet at least two times with water to remove water-soluble proteins

- after washing the pellet: incubate the pellet in denaturation buffer for 60 min, 4 °C with vertical rotator

- final concentration in denaturation buffer: 0.5 mg wet biomass per mL

- centrifuge (60 min, >17,000 g, 4 °C)

- the higher the speed, the better the result

- collect supernatant and incubate the pellet again in denaturation buffer (60 min, 4 °C, vertical rotator)

- centrifuge (60 min, >17,000 g, 4 °C)

- collect supernatant and discard pellet

Ultra-/Diafiltration

- Arrange the filtration module as shown on the right side.

- Microfiltration (0.22 µm) or cross flow filtration 300 kDa ( we used a Milipore Pellicon XL 300) membrane of sample before ultrafiltration.

- For concentrating the sample just filter it until the desired volume is left in the feed reservoir. For diafiltration (e.g. buffer exchange, desalting) dilute the feed reservoir several times and filter continously.

- Used membranes: [http://www.millipore.com/catalogue/module/C7493 Milipore Pellicon XL 50] or XL 100 membranes

- 50 or 100 kDa cut-off

- 50 cm2 filtration area

- tangential flow filter

- Hydrophilic polyvinylidene fluoride membrane

- Used pump: SciLog TANDEM 1081 peristaltic pump

- flow rate during filtration: 40 mL min-1

Ion exchange chromatography (IEX) for S-layer proteins from Corynebacterium

- used column: DEAE HiTrap 1 mL with GE Healthcare ÄKTA

- flow rate: 1 mL min-1

- equilibrate column with 5 column volumes of binding buffer

- inject sample and wash column with 5 column volumes of binding buffer

- elute S-layer with 40 % binding / elution buffer mix

- elute remaining proteins with 100 % elution buffer

Ni-NTA spin columns

denaturating

non-denaturating

His-tag affinity chromatography

- Column: 1 mL HisTrap FF crude by [http://www.gehealthcare.com/ GE Healthcare]

- Harvest cells by centrifugation (10000 g, 10 min, 4 °C)

- Discard supernatant and freeze the pellet at -20 °C for at least 30 min

- Resuspend pellet in 5 mL of binding buffer for each gram of cell paste

- Wash column with 5 - 10 mL deionized water

- Equilibrate column with 5 - 10 mL of binding buffer

denaturing

- Mechanical lysis:

- Sonication on ice (approx. 5 min) with Sonifier 450 by [http://www.bransonultrasonics.com/ Branson]

- Centrfigate for at 10000 g for 30 min at 4 °C

non-denaturing

- Enzymatic lysis:

- Add 0.2 mg L-1 lysozyme, 3 Units per mL culture volume and 1 mM MgCL2

- Stir for 30 min at 4 °C

- Centrfigate for at 10000 g for 30 min at 4 °C

Measuring of [http://partsregistry.org/Part:BBa_E1010 mRFP]

- Take at least 500 µL sample for each measurement (200 µL is needed for one measurement) so you can perform a repeat determination

- Freeze samples at -80 °C for storage

- To measure the samples thaw at room temperature and fill 200 µL of each sample in one well of a black, flat bottom 96 well microtiter plate (perform at least a repeat determination)

- Measure the fluorescence in a platereader (we used a [http://www.tecan.com/platform/apps/product/index.asp?MenuID=1812&ID=1916&Menu=1&Item=21.2.10.1 Tecan Infinite® M200 platereader]) with following settings:

- 20 sec orbital shaking (1 mm amplitude with a frequency of 87.6 rpm)

- Measurement mode: Top

- Excitation: 584 nm

- Emission: 620 nm

- Number of reads: 25

- Manual gain: 100

- Integration time: 20 µs

Sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE)

This analytical Method can be used for separation and identification of proteins according to their electrophoretic mobility. The mobility is a function of length of the molecular weight. Proteins that have identical charge per unit mass due to binding of SDS results in an equal electrophoretic mobility.

Pouring the polyacrylamide gel

- Make a master mix for the stacking and separating gel without adding ammonium persulfate and TEMED.

- Aliquote 6,5 mL for each separating and 2,5 mL for each stacking gel.

- Add ammonium persulfate and TEMED to each separating gel aliquote and pour the solution quickly into your gel casting form. Leave about 2 centimeters below the bottom of the comb for the stacking gel.

- Layer isopropanol on top of the gel.

- Leave the separating gel at room temperature for >60 minutes to polymerize.

- Remove isopropanol and wait until the surface is dry.

- Add ammonium persulfate and TEMED to each separating gel aliquote and pour the solution quickly into your gel casting form.

- Insert comb without getting bubbles stuck underneath

- Leave the gel at room temperature for >60 minutes to polymerize.

- For storage

- Remove sealing and store the gel wrapped in moistened paper towel at 4°C.

Preparing the sample

- Mix your protein mixture 4:1 with Laemmli-buffer (30 mL protein solution + 10 mL Laemmli-buffer)

- Heat for 5 minutes at 95 °C.

Running the gel

- Remove sealing, put the polymerized gel into gel box and pour SDS running buffer into the negative and positive electrode chamber.

- Remove comp without destroying the gel pocket.

- Pipet the sample into the gel pockets, adjusting the volume according to the amount of protein in your sample. Make sure to include a lane with molecular weight standards (PageRuler Prestained Protein Ladder™ (Fa. Fermentas)) to determinate the molecular weight of your sample.

- Connect the power lead and run the stacking gel with 10 mA until the blue dye front enters the separating gel.

- Raise amperage up to 20 mA for running the separating gel.

- When the distance of the lowest molecular weight standard lane to the gel end is down to 0,5 cm stop the electrophoresis by turning off the power supply.

Polyacrylamide gel staining

Colloidal Coomassie Blue staining

Modified staining protocol from [http://http://newjournal.kcsnet.or.kr/main/j_search/j_abstract_view.htm?code=B021105&qpage=j_search&spage=b_bkcs&dpage=ar Kang et al., 2002].

- agitate the staining solution at 37 °C over night to form the colloids

- After finishing the SDS-PAGE remove gel from gel casting form and tranfer it in to a box.

- Add 100 mL of the stainig solution to your polyacrylamid gel.

- Incubate the gel in the solution at room temperature until the protein bands got an intensive blue color. Shake the gel continuously during incubation.

- Remove the staining solution

- wash the gel with dH2O

- Incubate the gel in ddH2O (2-6h) for bleaching the background. Shake the gel continuously during incubation. If necessary replace the colored water with new one.

Fairbanks Coomassie staining

Modiefid steining protocol from Fairbanks et al., (1971).

- After finishing the SDS-PAGE remove gel from gel casting form and tranfer it in to a box with 100 mL of solution A.

- Heat the gel in a microwave for 2 min at 600 W.

- Shake the gel for 5-10 minutes.

- Remove solution A and wash the gel with dH2O.

- Add 100 mL of solution B and heat the gel in a microwave for 2 min at 600 W.

- Shake the gel for 5-10 minutes.

- Remove solution B and wash the gel with dH2O.

- Add 100 mL of solution C and heat the gel in a microwave for 2 min at 600 W.

- Shake the gel for 5-10 minutes.

- Remove solution C and wash the gel with dH2O.

- For bleaching the background add 100 mL of solution D and heat the gel in a microwave for 2 min at 600 W.

- Shake the gel for 5-10 minutes.

- Remove solution D and wash the gel with dH2O. If necessary repeat the last 3 steps with solution D.

Silver staining

Modified staining protocol from

- After finishing the SDS-PAGE remove gel from gel casting form and tranfer it in to a box.

- Add 50 mL of fixation solution and incubate the gel 1 to 24 h. The formaldehyde (37 %) must be added to the solution short time before.

- Remove the fixation solution and wash the gel 3 times (1-20 min) with 50 mL of 50 % (v/v) ethanol.

- Add 50 mL of thiosulfate solution and incubate the gel exactly for 1 min. If the gel incubates to long the background becomes to dark.

- Remove thiosulfate solution and wash the gel 3 times (20 s) with dH2O.

- Add 50 mL of impregnation solution and icubate the gel for 15 to 20 min. The formaldehyde (37 %) must be added to the solution short time before.

- Remove impregnation solution and wash the gel 2 times (20 s) with dH2O.

- Add 50 mL of developing solution and incubate the gel until protein bands become visible.

- Remove the developing solution immediately and wash the gel for 10 to 20 s with dH2O.

- Add 50 mL of stop solution and incubate the gel 10 to 20 s.

- Remove the stop solution and wash the gel for 1 min with dH2O.

Tryptic digest of gel lanes for analysis with MALDI-TOF

Note:

- Make sure to work under a fume hood.

- Do not work with protective gloves to prevent contamination of your sample with platicizers.

Reaction tubes have to be cleaned with 60% (v/v) CH3CN, 0,1% (v/v) TFA. Afterwards the solution has to be removed completely followed by evaporation of the tubes under a fume hood. Alternatively microtiter plates from Greiner® (REF 650161) can be used without washing.

- Cut out the protein lanes of a Coomassie-stained SDS-PAGE using a clean scalpel. Gel parts are transferred to the washed reaction tubes/microtiter plate. If necessary cut the parts to smaller slices.

- Gel slices should be washed two times. Therefore add 200 µL 30% (v/v) acetonitrile in 0,1 M ammonium hydrogen carbonate each time and shake lightly for 10 minutes. Remove supernatant and discard to special waste.

- Dry gel slices at least 30 minutes in a Speedvac.

- Rehydrate gel slices in 15 µL Trypsin-solution followed by short centrifugation.

- Gel slices have to be incubated 30 minutes at room temperature, followed by incubation at 37 °C overnight.

- Dry gel slices at least 30 minutes in a Speedvac.

- According to the size of the gel slice, add 5 – 20 µL 50% (v/v) ACN / 0,1% (v/v) TFA.

- Samples can be used for MALDI measurement or stored at -20 °C.

Trypsin-solution: 1 µL Trypsin + 14 µL 10 mM NH4HCO3

- Therefore solubilize lyophilized Trypsin from Promega® in 200 µL of provided buffer and incubate for 15 minutes at 30 °C for activation. For further use it can be stored at -20 °C.

Preparation and Spotting for analysis of peptides on Bruker AnchorChips

- Spot 0,5 – 1 µL sample aliquot

- Add 1 µL HCCA matrix solution to the spotted sample aliquots. Pipet up and down approximately five times to obtain a sufficient mixing. Be careful not to contact the AnchorChip.

Note: Most of the sample solvent needs to be gone in order to achieve a sufficiently low water content. When the matrix solution is added to the previously spotted sample aliquot at a too high water content in the mixture, it will result in undesired crystallization of the matrix outside the anchor spot area.

- Dry the prepared spots at room temperature

- Spot external calibrants on the adjacent calibrant spot positions. Use the calibrant stock solution (Bruker’s “Peptide Calibration Standard II”, Part number #222570), add 125 µL of 0,1% TFA (v/v) in 30% ACN to the vial. Vortex and sonicate the vial.

- Mix the calibrant stock solution in a 1:200 ratio with HCCA matrix and deposit 1 µL of the mixture onto the calibrant spots.

Bisphenol A analysis

Extraction with ethylacetate

- mix 100 µL culture supernatant with 100 µL internal standard ( bisphenol F, 100 µg L-1)

- add 200 µL ethylacetate (HPLC grade) for extraction

- vortex (30 s)

- centrifuge for phase separation (5 min, 5000 g)

- take a bit from upper phase and put it in a clean eppi

- SpeedVac at 40 °C to remove ethlyacetate

- solve remaining BPA in water (HPLC grade), vortex (30 s)

- solubility of BPA in water only 300 mg L-1

- for LC-MS analysis of BPA, 300 mg BPA L-1 is definitely enough

- if you want to detect or expect higher concentrations of BPA, solve it in an acetonitrile-water-mix

HPLC method

- C18 reverse phase column

- Isocratic method: 45 % Acetonitrile

- Flow = 0.6 mL min-1

- UV-detection at 227 nm

- Internal standard: 100 mg L-1 Bisphenol F (BPF)

- Column:

- Eurospher II 100-5 C18p by [http://www.knauer.net/ Knauer]

- Dimensions: 150 x 4.6 mm with precolumn

- Particle size: 5 µm

- Pore size: 100 Å

- Material: silica gel

- Software:

- Clarity (Version 3.0.5.505) by [http://www.dataapex.com/ Data Apex]

- Autosampler:

- Midas by [http://www.spark.nl/ Spark Holland]

- Tray cooling: 10 °C

- Pump:

- L-6200A Intelligent Pump by [http://www.hitachi.com/ Hitachi]

- UV-Detector:

- Series 1050 by [http://www.hp.com/ Hewlett Packard]

NAD+ detection

For the [http://www.molecular-beacons.com/MB_SC_design.html design of molecular beacons] different available tools may help you so that a correct functionality is ensured under defined assay conditions. All measurements were made in the NAD+ bioassay buffer.

Characterisation of molecular beacons

Preferentially, use a complementary oligonucleotide (target) as well as two enshortened oligonucleotides (split target) for [http://www.molecular-beacons.com/MB_SC_protocol.html#cap3 characterising the molecular beacon] in its closed and open state. In this way you can verify simultaneously the ineffectiveness of the split target to reach the molecular beacon`s open state.

- Optimal wavelengths:

- Determine the emission spectrum of your molecular beacon by initially using a literature value for the exctintion wavelength of the labeled fluorophore. For this add 10 µL of 1 µM molecular beacon in 200 µL NAD+ bioassay buffer, mix thoroughly and wait 2 min until measuring the fluorescence with a spectrofluorometer at an defined temperature (optimally 37 °C) .

- Add 10 µL of 2 µM either target or split target and shake at least 6 min until measuring the fluorescence again (when equilibrium is reached).

- Repeat the procedure to determine the extinction spectrum using the self-calculated optimal emission wavelength for your fluorophore/quencher combination. For further fluorescence measurements use the extinction wavelength for which the difference between the molecular beacons's closed state and the open state signals is maximal.

- Thermal profile analysis:

- Prepare a 30 µL reaction mix composed of NAD+ bioassay buffer and 1 µM molecular beacon. In a separate sample add 2 µM either target or split target.

- Use a spectrofluorometric thermal cylcer to dertemine the fluorescence as a function of temperature. Start at 80 °C and decrease the temperature stepwise in 1 °C intervals holding each temperature for 1 min and measuring the fluorescence at the end of each step.

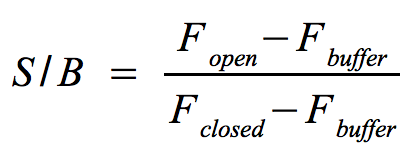

- Signal-to-background ratio (S/B):

- The approach is quite similar to the one that determines the optimal wavelengths which should be used to monitor the fluorescence of the NAD+ bioassay buffer (Fbuffer) and the added molecular beacon (Fclosed) as well as the target (Fopen) or split target. Monitor the fluorescence at the optimal wavelengths until the equilibrium is reached each time before you add a new component.

- The signal-to-background ratio can be calculated as shown on the right. Finally, compare the signal-to-background ratios after adding the target and split target to check whether the split target has an effect on the melting of the molecular beacon's hairpin structure.

- Imaging:

- Prepare a 200 µL reaction mix composed of NAD+ bioassay buffer and 500 nM molecular beacon in a PCR tube. In a separate sample add 600 µM either target or split target. Excitate the samples by a UV transilluminator and take images preferably with a camera that can detect different colours.

Purification of DNA ligase

The purification of the overexpressed NAD+-dependent DNA ligase gene (BBa_K525710) in E. coli was performed under native conditions and Ni-NTA columns were used utilizing the recombinant protein`s C-terminal 6xHis-tag.

- Cultivation

- Prepare an overnight culture of [http://www.promega.com/products/cloning-and-dna-markers/cloning-tools-and-competent-cells/bacterial-strains-and-competent-cells/single-step-_krx_-competent-cells/ E. coli KRX] carrying the plasmid with DNA ligase (BBa_K525710) in 30 ml LB medium containing 20 μg mL-1 chloramphenicol at 37 °C.

- Dilute the overnight culture in 100 ml autoinduction medium (20 μg mL-1 chloramphenicol added) to an OD600 = 0,1 and harvest the cells after 4 h growth at 37 °C.

- Use the centrifuged cells immediately for protein purification or store them at -20 °C.

- Small-scale purification

- Resuspend a pellet derived from 5 ml cell culture volume in 630 μl NPI-10.

- Add 70 μl lysozyme (10 mg/ml) as well as 25 Units benzonase nuclease and mix thoroughly.

- Incubate on ice for 30 min.

- Centrifuge the lysate for 30 min at 12000 g (4 °C). Collect the supernatant (cleared lysate).

- Prepare a [http://www.qiagen.com/products/protein/purification/qiaexpressproteinpurificationsystem/ni-ntaspincolumns.aspx?ShowInfo=1 Ni-NTA spin column] ([http://www.qiagen.com/default.aspx QIAGEN]) by equilibration with 600 μl NPI-10 and centrifugation for 2 min at 890 g (4 °C).

- Load up to 600 μl cleared lysate onto the [http://www.qiagen.com/products/protein/purification/qiaexpressproteinpurificationsystem/ni-ntaspincolumns.aspx?ShowInfo=1 Ni-NTA spin column] and centrifuge for 5 min at 270 g (4 °C). Collect the flow-through.

- Wash the [http://www.qiagen.com/products/protein/purification/qiaexpressproteinpurificationsystem/ni-ntaspincolumns.aspx?ShowInfo=1 Ni-NTA spin column] with 600 μl NPI-20 and centrifuge for 2 min at 890 g (4 °C). Repeat this step and collect flow-through each time.

- Elute the protein with 300 μl NPI-500 and centrifuge for 2 min at 890 g (4 °C). Repeat this step and collect flow-through each time.

- For centrifugal ultrafiltration use [http://www.sartorius-stedim.com/DE/en/Centrifugal-Ultrafiltration--Vivaspin-%26-Centrisart/Vivaspin-500/VS0111-VIVASPIN-500-5%2C000-MCWO-PES-25-BOX/6htcki6uex7/m8qc5rabaox/n8uj9p1cyz4/article.htm Vivaspin 500] concentrators ([http://www.sartorius.de/index.php?id=156&no_cache=1 Sartorius]) with a 5000 molecular weight cut-off PES membrane. Repeat the procedure three times by adding DNA ligase buffer (4 °C) for buffer exchange (remove of imidazole).

- Check each purification step and especially the purity of the protein in the final condition by SDS-PAGE analysis.

- Determine the protein concentration with a Bradford Protein Assay.

- For long-time storage keep the protein at -20 °C.

- If the binding conditions are not effective enough you can reduce the imidazole concentration in NPI-10 to 1-5 mM. If the eluate contains unspecifically bound proteins maybe a washing step with NPI-10 containing 50 mM or 100 mM imidazole could help to get higher purity.

- Large-scale purification

- Resuspend a cell culture pellet in 5 ml binding buffer per gramm biomass.

- Add 10 mM MgCl2, 1 mg/ml lysozyme] as well as 5 Units benzonase nuclease per 1 ml cell culture volume and mix thoroughly.

- Incubate at 4 °C for 30 min.

- Centrifuge the lysate for 30 min at 10000 g (4 °C). Collect the supernatant (cleared lysate).

- Prepare a [http://www.gelifesciences.com/aptrix/upp01077.nsf/Content/Products?OpenDocument&moduleid=165904 HisTrap™ FF crude column] ([http://www.gelifesciences.com/aptrix/upp01077.nsf/Content/life-sciences_homepage GE Healthcare]) by equilibration with 5 column volumes of binding buffer. The following steps have to be performed at 4 °C.

- Load the cleared lysate onto the [http://www.qiagen.com/products/protein/purification/qiaexpressproteinpurificationsystem/ni-ntaspincolumns.aspx?ShowInfo=1 HisTrap™ FF crude column] and collect flow-through.

- Wash the [http://www.qiagen.com/products/protein/purification/qiaexpressproteinpurificationsystem/ni-ntaspincolumns.aspx?ShowInfo=1 HisTrap™ FF crude column] with 10 column volumes of binding buffer and collect flow-through.

- Elute the protein successively with 5 ml of buffers that contain different concentrations of imidazole (e.g. binding buffer with 40, 60, 100, 300 and 500 mM imidazole) and collect flow-through in 1 ml fractions.

- For centrifugal ultrafiltration use [http://www.sartorius-stedim.com/DE/de/Zentrifugal-Ultrafiltration--Vivaspin-%26-Centrisart/Vivaspin-15/VS1501-VIVASPIN-15-10%2C000-MWCO-PES-10-BOX/6htcki6uex7/1b11mt9gskl/kn4oouwu6g3/article.htm Vivaspin 15] concentrators ([http://www.sartorius.de/index.php?id=156&no_cache=1 Sartorius]) with a 10000 molecular weight cut-off PES membrane. Repeat the procedure three times by adding DNA ligase buffer (4 °C) for buffer exchange (remove of imidazole).

- Check each purification step and especially the purity of the protein in the final condition by SDS-PAGE analysis.

- Determine the protein concentration with a Bradford Protein Assay.

- For long-time storage keep the protein at -20 °C.

Deadenylation

The majority of purified DNA ligase from [http://www.promega.com/products/cloning-and-dna-markers/cloning-tools-and-competent-cells/bacterial-strains-and-competent-cells/single-step-_krx_-competent-cells/ E. coli KRX] is usually in the adenylated form. But only the apoenzyme is really useful for the [http://pubs.acs.org/doi/abs/10.1021/ac102742k NAD+ bioassay] so that the AMP moiety has to be removed.

- Mix the purified DNA ligase with deadenylation buffer and incubate for 10 min at 37 °C.

- Use [http://www.sartorius-stedim.com/DE/de/Zentrifugal-Ultrafiltration--Vivaspin-%26-Centrisart/Vivaspin-15/VS1501-VIVASPIN-15-10%2C000-MWCO-PES-10-BOX/6htcki6uex7/1b11mt9gskl/kn4oouwu6g3/article.htm Vivaspin 15] concentrators ([http://www.sartorius.de/index.php?id=156&no_cache=1 Sartorius]) with a 10000 molecular weight cut-off PES membrane for buffer exchange at 4 °C. Repeat the procedure at least three times by adding DNA ligase buffer (remove of NMN and formed NAD+).

- Check the deadenylation process by SDS-PAGE analysis. If the deadenylation was successful there should not be a double band indicating both forms of DNA ligase.

- Determine the protein concentration with a Bradford Protein Assay.

- For long-time storage keep the protein at -20 °C.

NAD+ bioassay

- Prepare a 80 μl aliquot composed of 250 nM molecular beacon and 250 nM split target in NAD+ bioassay buffer.

- Incubate for 8 min at 37 °C.

- Add 6 Units of deadenylated DNA ligase (approximately ... ng).

- Monitor the fluorescence with a spectrofluorometer at 37 °C and wait until it reaches equilibrium.

- Add NAD+ in different final concentrations (e.g. 0, 0.3, 0.5, 5, 10, 30, 40, 80, 200, 300, 500, 1000 nM), stirr shortly and monitor the fluorescence at 37 °C again.

- Determine the initial enhancement rate of flourescence intensity for each NAD+ concentration.

- For the calibration curve plot the initial velocity against the NAD+ concentration.

Used enzymes

| Enzyme | Producer |

|---|---|

| AgeI | [http://www.fermentas.de/product_info.php?info=p247 Fermentas] |

| DpnI | [http://www.fermentas.de/product_info.php?info=p296 Fermentas] |

| EcoRI | [http://www.fermentas.de/product_info.php?info=p336 Fermentas] |

| GoTaq DNA-polymerase | [http://www.promega.com/products/pcr/routine-pcr/gotaq-pcr-core-systems/ Promega] |

| KOD Hotstart DNA-polymerase | [http://www.merck-chemicals.com/germany/life-science-research/kod-hot-start-dna-polymerase/EMD_BIO-71086/p_iFCb.s1O874AAAEj2Bl9.zLX Novagen] |

| NgoMIV | [http://www.neb.com/nebecomm/products/productR0564.asp NEB] |

| OneTaq DNA-polymerase | [http://www.neb.com/nebecomm/products/productM0480.asp NEB] |

| Pfu DNA-polymerase | [http://www.promega.com/products/pcr/routine-pcr/pfu-dna-polymerase/ Promega] |

| PstI | [http://www.fermentas.de/product_info.php?info=p458 Fermentas] |

| Phusion HF DNA-polymerase | [http://www.finnzymes.com/pcr/phusion_high_fidelity_dna_polymerase.html Finnzymes] |

| Shrimp alcaline phosphatase | [http://www.fermentas.de/product_info.php?info=p592 Fermentas] |

| SpeI | [http://www.fermentas.de/product_info.php?info=p202 Fermentas] |

| T4-DNA-Ligase | [http://www.fermentas.de/product_info.php?info=p580 Fermentas] |

| T5 exonuclease | [http://www.neb.com/nebecomm/products/productM0363.asp NEB] |

| taq DNA Ligase | [http://www.neb.com/nebecomm/products/productM0208.asp NEB] |

| taq DNA-polymerase | [http://www.bioline.com/h_prod_detail.asp?itemid=219 Bioline] |

Used Kits

| Function | Name |

|---|---|

| Molecular Cloning | [http://www.fermentas.de/product_info.php?info=p1620 Fermentas CloneJET™ PCR Cloning Kit] |

| Plasmid purification | [http://www.fermentas.de/product_info.php?info=p874 Fermentas GeneJET™ Plasmid Miniprep Kit] |

| Plasmid purification | [http://www.promega.com/b/de/minis/default.aspx?utm_source=Promega&utm_medium=Online&utm_campaign=Online_DEPureYield100Preps_Promega_HP_Banner Promega PureYield™ Plasmid Preps] |

| PCR Cleanup | [http://www.mn-net.com/tabid/10745/default.aspx Macherey Nagel NucleoSpin® Extract II] |

| PCR Cleanup | [http://www.promega.com/products/dna-and-rna-purification/dna-fragment-purification/wizard-sv-gel-and-pcr-clean_up-system/ Promega Wizard® SV Gel and PCR Clean-Up] |

| PCR core system | [http://www.promega.com/products/pcr/routine-pcr/gotaq-pcr-core-systems/ Promega GoTaq® PCR Core System I] |

Media, buffer, solutions etc.

Ampicillin stock solution

- Solubilize 100 mg mL-1 Ampicillin

- Store at -20 °C

Chloramphenicol stock solution

- Solubilize 20 mg mL-1 Chloramphenicol

- Store at -20 °C

TAE buffer

For 1 L of 50 x TAE buffer you need:

- 242.48 g Tris

- 41.02 g Sodiumacetate

- 18.612 g EDTA

- Adjust pH to 7.8 with acetic acid

- Solve in dH2O

10 mL of the stock is diluted in 1 L dH2O for the gel electrophoresis (0.5 x TAE buffer).

DNA loading buffer

- 50 % (v/v) glycerol

- 1 mM EDTA

- 0.1 % (w/v) bromphenol blue

- Solve in ddH2O

LB medium

For 1 L of LB medium you need:

- 10 g Trypton

- 5 g yeast extract

- 10 g NaCl

- 12 g Agar-Agar (for plates)

- Adjust pH to 7.4

Autoinduction medium for KRX

This medium is based on the LB medium.

After heat sterilization of 900 mL add the following chemicals

- 5 mL of a 200 g L-1 steril L-rhamnose stock solution (final concentration 2 g L-1 L-rhamnose)

- 2,5 mL of a 200 g L-1 steril glucose stock solution (final concentration 0,5 g L-1 glucose)

- if necessary add antibiotics

- Cm: 1 mL of a 20 μg mL-1 Cm stock solution (final concentration 2 μg L-1)

- Amp: 1 mL of a 100 μg mL-1 Amp stock solution (final concentration 100 μg L-1)

- fill-up to 1 L with steril ddH2O

M9 medium

For 250 mL M9 medium you need 175 mL sterile water (for plates add 4 g Agar-Agar as well). Then add (in the following order:

- 250 µL 100 mM CaCl2

- 2.5 mL trace salts

- store this stock solution in the dark

- 250 µL MgSO4

- 250 µL 50 mM FeCl3 / 100 mM citrate (one solution, citrate is iron carrier)

- store this stock solution cold and in the dark

- carbon source stock solution (e.g. glucose)

- 50 mL 5x M9 salts stock solution

- 64 g L-1 Na2HPO4 * 7 H2O

- 15 g L-1 KH2PO4

- 2.5 g L-1 NaCl

- 5 g L-1 NH4Cl

- antibiotic stock solution

- fill up to 250 mL with sterile water

HSG medium

- 14.9 g L-1 glycerine

- 13.5 g L-1 soy peptone

- 7 g L-1 yeast extract

- 2.5 g L-1 NaCl

- 2.3 g L-1 K2HPO4

- 1.5 g L-1 KH2PO4

- 0.249 g L-1 MgSO4 * 7 H2O

5x isothermal reaction buffer for Gibson assembly

storage -20˚C

- 3 mL of 1 M Tris-HCl (pH 7.5)

- 150 µL of 2 M MgCl2,

- 60 µL of 100 mM dGTP

- 60 µL of 100 mM dATP

- 60 µL of 100 mM dTTP,

- 60 µL of 100 mM dCTP

- 300 µL of 1 M DTT

- 1.5 g PEG-8000 and

- 300 µL of 100 mM NAD

Cold osmotic shock buffers for the release of periplasmic protein fraction

Cell fractionating buffer #1 (pH 8)

- 0,2 M Tris

- 200 g L -1 sucrose

- 0,1 M EDTA

Cell fractionating buffer #2 (pH 8)

- 0,01 M Tris

- 0,005 M MgSO4

Denaturation buffer for inclusion bodies

- 6 M urea

- 50 mM Tris-HCl

- 10 mM MgCl2

Buffers for S-layer IEX

Binding Buffer:

- 25 mM Sodiumacetate, pH 6

- 25 mM NaCl

Elution Buffer:

- 25 mM Sodiumacetate, pH 6

- 1 M NaCl

SDS-PAGE gel

The following amouts are for one gel. Stacking gel 5 %:

- 775 μL H2O

- 1.25 mL 0,25 M Tris (pH 6,8)

- 425 μL Bis/Acrylamide (0,8 %, 30 %)

- 50 μL 5 % SDS

- 25 μL 10 % Ammonium persulfate

- 3 μL TEMED

Separating gel 12 %:

- 1.5 mL H2O

- 2.8 mL 1 M Tris (pH 8,8)

- 3.0 mL Bis/ Acrylamide (0,8%, 30%)

- 150 μL 5% SDS

- 37.5 μL 10% Ammonium persulfate

- 5 μL TEMED

SDS running buffer

- 25 mM Tris [pH 8,3]

- 192 mM Glycerol

- 0,1 % SDS

4x Laemmli-buffer

- 250 mM Tris-HCl

- 40 % [v/v] Glycerol

- 20 % [v/v] 2-Mercapthoethanol

- 80 g L-1 SDS

- 0,04 g L-1 BPB

Colloidal Coomassie Brilliant Blue G-250 staining solution

for 1 L staining solution

- dissolve 50 g L-1 (NH4)2SO4 in ddH2O

- add 10 % (v/v) ethanol

- dissolve 0,2 g L-1 Coomassie Brilliant Blue G-250

- add 2 % (v/v) phosphoric acid

- fill up to 1 L with ddH2O

Fairbanks Coomassie staining solutions

Solution A:

- 25 % (v/v) ispropanol

- 10 % (v/v) acetic acid

- 0,5 g L-1 Coomassie Brilliant Blue R-250

Solution B:

- 10 % (v/v) ispropanol

- 10 % (v/v) acetic acid

- 0,05 g L-1 Coomassie Brilliant Blue R-250

Solution C:

- 10 % (v/v) acetic acid

- 0,025 g L-1 Coomassie Brilliant Blue R-250

Solution D:

- 10 % (v/v) acetic acid

Silver staining solutions

Fixation solution:

- 50 % (v/v) ethanol

- 12 % (v/v) acetic acid

- 1 mL L-1 formaldehyde (37 %)

Thiosulfate solution:

- 0.1 g L-1 Na2S2O3

Impregnation solution:

- 2 g L-1 silver nitrate (AgNO3)

- 0.75 mL L-1 formaldehyde (37 %)

Developing solution:

- 120 g L-1 sodium carbonate (Na2CO3)

- 1 mL L-1 formaldehyde (37 %)

Stop solution:

- 18.6 g L-1 EDTA

Binding buffer

- 20 mM Na3PO4, pH 7,4

- 500 mM NaCl

- 20 mM Imidazole

NPI-10 (lysis buffer)

- 50 mM NaH2PO4, pH 8,0

- 300 mM NaCl

- 10 mM Imidazole

- 2 mM PMSF

NPI-20 (wash buffer)

- 50 mM NaH2PO4, pH 8,0

- 300 mM NaCl

- 20 mM Imidazole

NPI-500 (elution buffer)

- 50 mM NaH2PO4, pH 8,0

- 300 mM NaCl

- 500 mM Imidazole

Deadenylation buffer

- 20 mM Tris-HCl, pH 7,5

- 50 mM NaCl

- 4 mM MgCl2

- 1 mM EDTA

- 1 mM DTT

- 1 mM NMN

DNA ligase buffer

- 20 mM Tris-HCl, pH 7,5

- 50 mM NaCl

- 20 % [v/v] Glycerol

NAD+ bioassay buffer

- 50 mM Tris-HCl, pH 8,0

- 10 mM MgCl2

- 2,5 mM CaCl2

- 5 mM DTT

- 0,05 % BSA

Used chemicals

| Chemical | Producer | Purity |

|---|---|---|

| Acetonitrile | VWR | 99.9 %, HPLC Grade |

| Bisphenol A | [http://www.sigmaaldrich.com/catalog/Lookup.do?N5=All&N3=mode+matchpartialmax&N4=bisphenol+a&D7=0&D10=bisphenol+a&N1=S_ID&ST=RS&N25=0&F=PR Sigma] | 97 % |

| Bisphenol F | [http://www.alfa.com/de/GP100W.pgm?DSSTK=A11417&rnd=097380668 Alfa Aesar] | 98 % |

| Ethylacetate | VWR | > 99.5 %, p.a. |

| Isopropyl β-D-1-thiogalactopyranoside | [http://www.carlroth.com/catalogue/catalogue.do;jsessionid=D5D58FA281A3E75342D9198F07546935?id=17413&favOid=000000010000911300020023&act=showBookmark&lang=de-de&market=DE Roth] | ≥ 99 % |

| L-rhamnose | [http://www.sigmaaldrich.com/catalog/ProductDetail.do?lang=de&N4=83650|FLUKA&N5=SEARCH_CONCAT_PNO|BRAND_KEY&F=SPEC Fluka] | ≥ 99 % |

| Chemical A | [http://www.link.com Producer A] | XX.X % |

"

"