Results

The strains transformed with the caretenogenic genes are a bright orange color due to all the beta-carotene they produce, as beta-carotene is an orange pigment. We confirmed its presence via HPLC using a standard.

On a first visual comparison of growth on dough media vs YPD we did see a significantly slower growth on dough media than on YPD. This is to be expected considering there is a large excess of nutrients on the YPD plates. There was still significant growth on the dough media plates however, enough to show that it would be viable to use in bread.

We then took it one step further and showed that baking bread with the Vitamin A yeast was possible.

Spectroscopy and HPLC

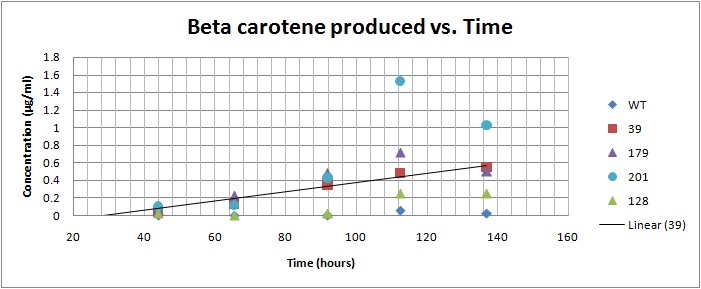

We have performed spectroscopy experiments, where we took measurements of the number of cells and amount of beta carotene produced at different time points. Beta carotene was extracted using hexane, as it would only isolate highly hydrophobic molecules like carotenoids. Based on the results, we can see that the production of beta-carotene over time increases at a linear rate, as the number of cells producing beta carotene increases. Production levels off at the later time points, corresponding to the observation that the media gets saturated. All genetically modified strains have shown significantly more beta carotene production than the wild type yeasts.

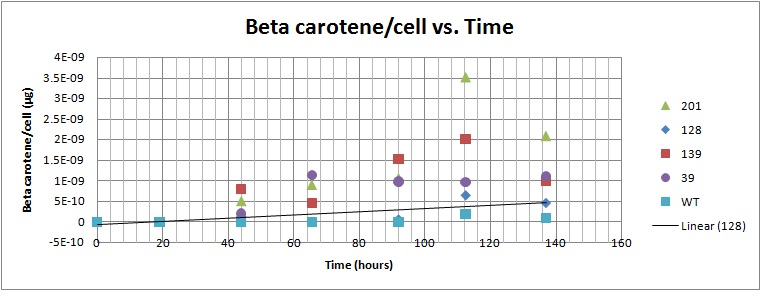

The normalized beta carotene/cell curve shows a fairly constant amount of beta carotene in each cell. It also provides initial conditions for our model used to optimize the beta carotene pathway.

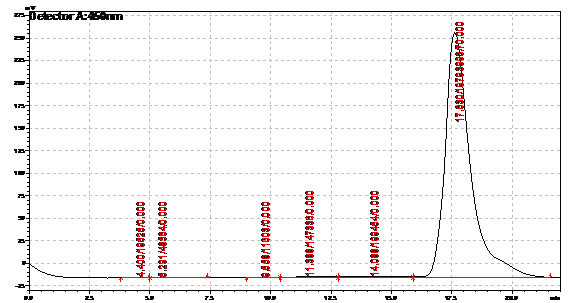

We have verified the presence of beta carotene in our extracts by performing HPLC analysis. A reverse phase column is used as it provides great sensitivity and accuracy, so that we would be able to isolate beta carotene from other similar carotenoids that may be present. Beta carotene elutes at around 18 mins, and our sample peaks are compared to the standards. HPLC also allows us to quantify beta carotene accurately.

Protein Purification

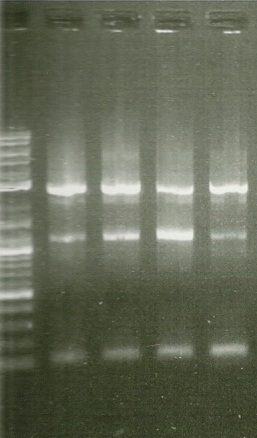

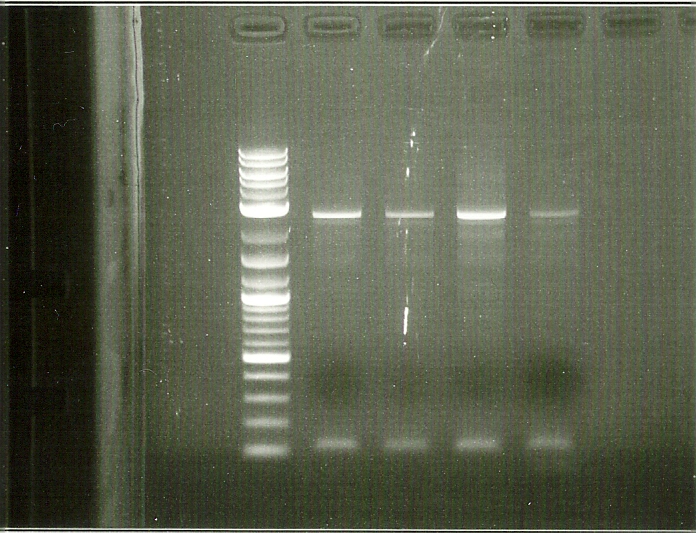

In order to perform enzyme kinetics assays, we needed to first purify our proteins of interest. From the beta carotene pathway, these enzymes were geranylgeranyl pyrophosphate synthase, phytoene desaturase, and a bifunctional phytoene synthase. Using a TEV-his6X-mCherry-KAN tag, we would be able to purify our enzyme with only one high efficiency purification step (Nickel Column Purification using His-tag) and characterize product with great accuracy through the use of anti-mCherry antibodies on the mCherry component of the tag. The goal of the PCR was to first produce a PCR product that contained the HIS-TEV-mCherry-KAN-CYC1tt tag. Another PCR would enable us to tag each of our genes of interest, which we could then transform into yeast for expression and purification. As depicted in the two PCR gels, both rounds of PCR proved to be successful, as we obtained a large signal for each of our tagged genes. These results enabled us to transform these tagged genes into yeast.

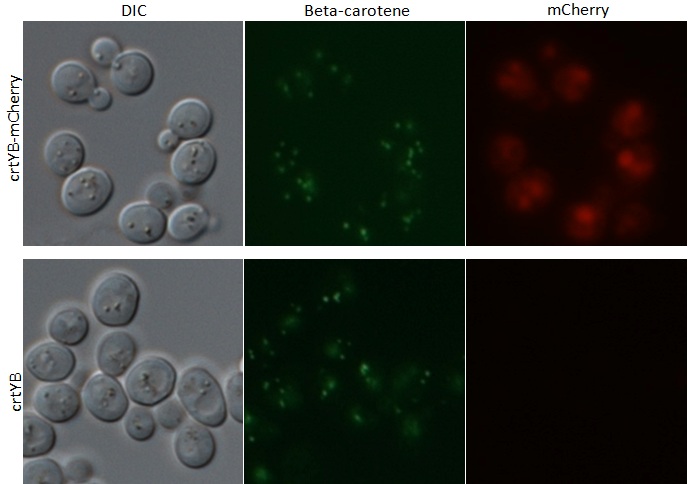

After transformation of our tagged genes, fluorescence microscopy was used to confirm the success of the transformation and expression of our tagged genes. Depicted in the fluorescence microscopy figure, the transformed yeast cells fluoresce red, which is evidence that our tagged mCherry (RFP) tagged genes are in fact present and being expressed in our yeast. Green fluorescence is seen in both wild type and transformed yeast, which is due to the autofluorescence inherent to beta carotene. In addition, the DIC (differential interference contrast) microscopy image shows the localization of our highly hydrophobic beta carotene molecules inside lipid droplets of the yeast cell.

References

1. High-Level Production of Beta-Carotene in Saccharomyces cerevisiae by Successive Transformation with Carotenogenic Genes from Xanthophyllomyces dendrorhous René Verwaal,1, Jing Wang,1 Jean-Paul Meijnen,1 Hans Visser,1,Gerhard Sandmann,2 Johan A. van den Berg,1, and Albert J. J. van Ooyen1*

"

"