Team:Paris Bettencourt/Experiments/Methodologies/Integration

From 2011.igem.org

Integration plasmid

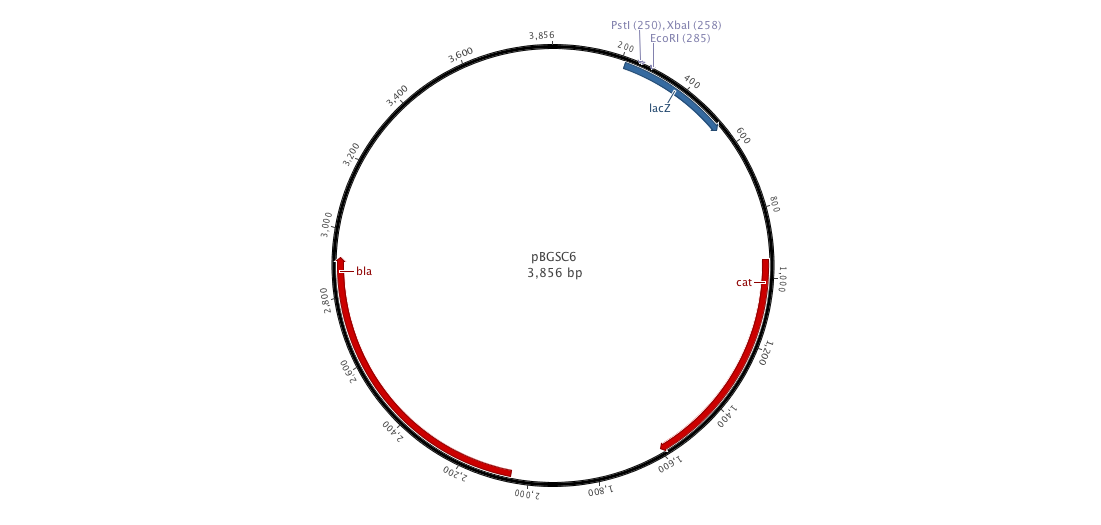

Since we have a lot of problems with the clonning of our parts into replivative plasmid we created, we decided to ;anaged a integrative plasmid which could give us certainly better results since contrary to the replicative plasm we cannot observe a varialibity in its expression. To do that, we created the biobriked plasmid pDCPKO from the Bacillus Genetic Stock Center under the name pBGCS6.

Into this plasmidm we cloned the both AmyE sequences created by the 2008 Imperial College of London team 5 (<partinfo>K143001</partinfo> and <partinfo>K090403</partinfo>)). What we want to do is to clone the whole plasmid into B.subtilis. Thus, we get our next new plasmid pDCPKO which one encodes chloramphenicol acetyl transferase selectable in either E.coli or B.subtilis (chloramphenicol 5μg/ml), β-lactamase selectable in E.coli only (ampicillin 100μg/ml).).

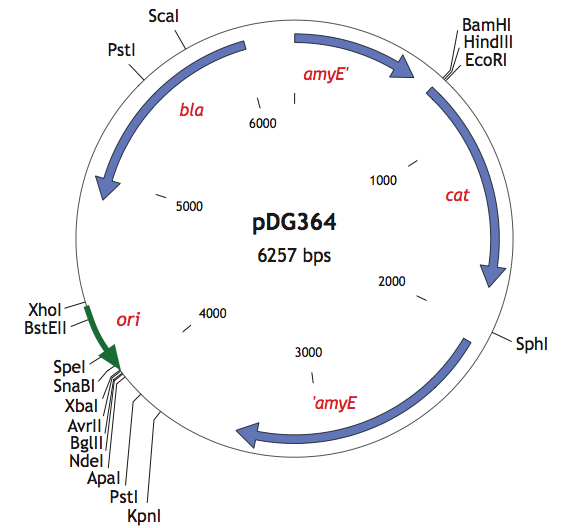

We chose to follow a second possibility in order to improve our chance of success for the integration parts. Thus, we used the plasmid pDG364 from Harald Putzer at ibpc which one encodes chloramphenicol acetyl transferase selectable in either E.coli or B.subtilis (chloramphenicol 5μg/ml), β-lactamase selectable in E.coli only (ampicillin 100μg/ml).

We designed primers with restriction site BamHI, which have been amplified by PCR into our parts. Finally, we cloned our parts into the plasmid pDG364 by cutting by BamHI and EcoRI.

Right now, we can clone each of our parts into this plasmid in order to get our final construct into B.subtilis.

To integrate our integrative plasmid into B.subtilis, we chose to use two different methods. The first one is the starvation methos which one is based on the natural competence in B.subtilis.The second method used to integrate our integrative plasmid in B.subtilis is based on the electroporation.

Starvation

MDCH medium

- Phosphate-citrate buffer (10 x PC) 10 x concentrated stock solution contains per liter : K2H PO4 (anhydrous) 107 g; KH2 PO4 (anhydrous) 60 g; Trisodium citrate (5 H2O) 10 g.

- Dilute stock solution, check pH of 1 x PC buffer and adjust (if necessary) to pH=7. (1 x PC corresponds to Spizizen's salts without ammonium sulfate)

- 10 ml MD medium : 1 x PC buffer 9.2 ml; Glucose (50 %, w/v) 0.4 ml; L-tryptophan (5 mg/ml) 0.1 ml; Ferric ammonium citrate (2.2 mg/ml) 0.05 ml; Potassium aspartate or potassium glutamate (100 mg/ml) 0.25 ml; 1 M MgSO4 0.03 ml.

- Add 0,2mL of casein hydrolysate in the MD medium

- A 10 ml preculture is grown overnight at room temperature in LM broth (liquid LB medium supplemented with auxotrophic requirements and 3 mM MgSO4). MDCH medium is prepared by adding 0.2 ml 5 % casein hydrolysate to 10 ml MD. Use the preculture to inoculate MDCH medium at an OD600 of about 0.05. Grow this culture at 37° C with shaking to To (transition from exponential to stationary phase). Sometimes, To do not appears and we can see a decrease of the OD: do not use the culture. Advice: launch 2 or 3 culture for each strain.

- Add 1 volume of fresh MD medium without casein hydrolysate to 1 volume of culture. Continue shaking at 37° C for 1 hour.

- Make aliquots of 500μL

- Add DNA (up to 1μg) and continue shaking in the presence of DNA for 20 minutes. Eventually, allow for expression of antibiotic resistance for 20mn (as described inJ. Bacteriol. (1988), 170 : 5093-5101) and plate.

- Cm: 5μg/mL; Spec: 50 to 100μg/mL; Kan: 5μg/mL, Erm: 1μg/mL with 25μg/mL of Lincomycin

Electroporation

- Reagents and Equipment needed: Mannitol, Sorbitol, Trehalose, LB, glycerol (99,5%) DNA (50 ng/μL), B. subtilis strain for transformation Cuvette (2mm), Gene Pulser (Bio-rad) set on 200 ohms and 25 μF (≈ 5 ms pulses) and 2 to 2.5 kV Centrifuge set at 3000g and 10 minutes Micropipettes: P2, P200, P1000 Pipettes: 25 mL, 10 mL, 5 mL

Day 1: preparation

- Growth medium: LB + 0.5 mol.L-1 sorbitol → expected final volume: 52 mL for 1 cell culture (including 1 mL for taring the absorbance machine)

_ msorbitol ≈ 4,736 g

- Electro-poration medium: de-ionized water + 0.5 mol.L-1 sorbitol + 0.5 mol.L-1 mannitol + 0.5 mol.L-1 trehalose + 10% glycerol (v/v) → expected final volume: ≈ 40 mL for 1 round of poration

_ msorbitol = mmannitol ≈ 3,643 g

_ mtrehalose ≈ 7,566 g

_ Vglycerol (99,5 %) ≈ 4 mL

- Recovery medium: LB + 0.5 mol.L-1 sorbitol + 0.38 mol.L-1 mannitol → expected final volume: ≈ 1 ml per poly... tube (Approximately 10 tubes ≈ 11 ml total)

_ msorbitol ≈ 1,002 g

_ mmannitol ≈ 0,761 g

Sterilise the solution: Filtration or autoclave.

Inoculate a falcon containing 10 ml of LBA with your bacillus strain and let it grow overnight (37°C with shaking).

Day 2: electro-poration

1) Monitor the OD600 of your overnight culture

2) In a 500 ml erlenmeyer: dilute your culture into 50mL of Growth Medium so that the OD 600 is 0.01

3) Let the culture grow (37°C with shaking) until OD600 is between 0.85 and 1

4) Cool the cells on ice for 5 minutes.

5) NOTE: KEEP ALL YOUR MATERIAL ON ICE AND ALWAYS MANIPULATE ON ICE FROM NOW ON, KEEP AS STERILE AS POSSIBLE.

6) Distribute evenly the culture into two falcons and centrifuge at 3000g for 10 minutes.

7) Get rid of supernatant, tap the falcon upside down on a piece of paper and detach the pellet.

8) Add 20 mL of ice-cold electro-poration medium to one falcon, suspend the cells and transfer the content to the other falcon. Re-suspend.

9) Centrifuge 3000g for 10 minutes.

10) Repeat step 8 and 9 (in only one falcon) with 10 mL, 5 mL, 2.5 mL and finally add 0.625 mL (1/80 of initial volume).

11) During the centrifugation time, prepare the poly... tubes (label them) with recovery medium in them and put the cuvettes on ice: 1 of each at least has to be a control of cells without DNA, then 1 for each transformant you wish to make.

12) Transfer in a cuvette: 60 μL of cells + 1 μL of DNA (50ng/μL; none if control).

13) Pulse the cuvette.

14) Transfer immediately the content into the poly... tube (STERILE CONDITIONS).

15) Repeat 13, 14 and 15 for the number of prepared cuvettes.

16) Incubate the poly... tubes at 37°C for 3 to 6 hours.

17) Prepare plates with antibiotics (none for the control).

18) Note: ≈ 25 ml of LBA per petri dish, make sure the antibiotic is well diluted, labeling should be obvious.

19) Plate max 150 μL of transformed cells per petri dish and let grow overnight.

"

"