Team:Edinburgh/Cellulases (MATLAB model)

From 2011.igem.org

(→Results) |

(→Results) |

||

| (20 intermediate revisions not shown) | |||

| Line 7: | Line 7: | ||

<p class="h1">Cellulases (MATLAB model)</p> | <p class="h1">Cellulases (MATLAB model)</p> | ||

| - | MATLAB is a general-purpose mathematical tool, developed by [http://www.mathworks.com Mathworks], and commonly used by engineers. Among other things, it can be used to solve ordinary differential equations ( | + | MATLAB is a general-purpose mathematical tool, developed by [http://www.mathworks.com Mathworks], and commonly used by engineers. Among other things, it can be used to solve ordinary differential equations (ODEs) by numerical integration. |

| - | An attempt was made to use MATLAB to model the degradation of <span class="hardword" id="cellulose">cellulose</span> into glucose in a biorefinery. But accurately predicting how much is converted in the <span class="hardword" id="synergy">synergistic</span> system (where enzymes are kept close together) is difficult without literature to provide the | + | An attempt was made to use MATLAB to model the degradation of <span class="hardword" id="cellulose">cellulose</span> into glucose in a biorefinery. But accurately predicting how much is converted in the <span class="hardword" id="synergy">synergistic</span> system (where enzymes are kept close together) is difficult without literature to provide the ODEs and the kinetic parameters. Therefore this model only looks at the free floating (non-synergistic) enzyme approach. It is <span class="hardword" id="deterministic">deterministic</span> and is set by a series of initial conditions. |

==Assumptions== | ==Assumptions== | ||

| - | The mathematical model is based on the | + | The mathematical model is based on the ODEs and kinetic parameters outlined in [http://onlinelibrary.wiley.com/doi/10.1021/bp034316x/full Kadam ''et al'' (2004)]. The following are its assumptions and basis: |

| + | * Underlying assumption: cellulose, <span class="hardword" id="cellobiose">cellobiose</span>, and glucose concentrations change continuously with time. | ||

* Rate equations assume enzyme <span class="hardword" id="adsorption">adsorption</span> follows the Langmuir isotherm model. | * Rate equations assume enzyme <span class="hardword" id="adsorption">adsorption</span> follows the Langmuir isotherm model. | ||

| - | * Glucose and | + | * Glucose and cellobiose, which are the products of cellulose <span class="hardword" id="hydrolysis">hydrolysis</span>, are assumed to "competitively inhibit enzyme hydrolysis". |

* All reactions are assumed to follow the same temperature dependency Arrhenius relationship (shown below). However, in reality it should be different for every enzyme component, "because of their varying degrees of thermostability, with β-glucocidase being the most thermostable. Hence the assumption is a simplification of reality". | * All reactions are assumed to follow the same temperature dependency Arrhenius relationship (shown below). However, in reality it should be different for every enzyme component, "because of their varying degrees of thermostability, with β-glucocidase being the most thermostable. Hence the assumption is a simplification of reality". | ||

* Conversion of cellobiose to glucose follows the <span class="hardword" id="mm">Michaelis-Menten</span> enzyme kinetic model. | * Conversion of cellobiose to glucose follows the <span class="hardword" id="mm">Michaelis-Menten</span> enzyme kinetic model. | ||

| Line 77: | Line 78: | ||

==Construction of Model== | ==Construction of Model== | ||

| - | The model was constructed using the numerical programme MATLAB. A script file was generated which holds the variable dictionary, constants, temperature dependency equations, ODE45 and plot command. | + | The model was constructed using the numerical programme MATLAB. A script file was generated which holds the variable dictionary, constants, temperature dependency equations, the "ODE45" differential equation solver, and the plot command. |

A separate function file to the script is created as script files can only operate on the variables that are coded into their m-files. R<sub>s</sub> (the substrate reactivity parameter) changes at every iteration because it is dependent on the S the substrate concentration at a given time, the substrate being cellulose. Therefore S at the first iteration is S<sub>0</sub>, the initial substrate concentration. At the second iteration S is the previous value calculated by the ODE, and so on. After each step the new value of S is fed into the function file and is used for calculating the reaction rate constant for cellobiose and glucose, etc. | A separate function file to the script is created as script files can only operate on the variables that are coded into their m-files. R<sub>s</sub> (the substrate reactivity parameter) changes at every iteration because it is dependent on the S the substrate concentration at a given time, the substrate being cellulose. Therefore S at the first iteration is S<sub>0</sub>, the initial substrate concentration. At the second iteration S is the previous value calculated by the ODE, and so on. After each step the new value of S is fed into the function file and is used for calculating the reaction rate constant for cellobiose and glucose, etc. | ||

| Line 95: | Line 96: | ||

Enzymes: Exo/endo-glucanase - 1 g/kg, β-glucosidase - 0.01 g/kg <br/> Temperature 35° C]] | Enzymes: Exo/endo-glucanase - 1 g/kg, β-glucosidase - 0.01 g/kg <br/> Temperature 35° C]] | ||

| - | Figure 1 is set with β-glucosidase at its maximum concentration and Figure 2 with Exo/endo-glucanase at maximum. This is to compare the effect of certain enzymes on cellulose degradation and glucose production. The result is consistent with what is expected. Exoglucanase chews away at the end of a cellulose chain, producing cellobiose sugars and endoglucanase cuts cellulose chanins in the centre, turning one chain into two. This concurs with the results, with Figure | + | Figure 1 is set with β-glucosidase at its maximum concentration and Figure 2 with Exo/endo-glucanase at maximum. This is to compare the effect of certain enzymes on cellulose degradation and glucose production. The result is consistent with what is expected. Exoglucanase chews away at the end of a cellulose chain, producing cellobiose sugars and endoglucanase cuts cellulose chanins in the centre, turning one chain into two. This concurs with the results, with Figure 1 modelling markedly higher amount of cellulose at the minimum amount of exo/endo-glucanase than that of Figure 2. Whereas β-glucosidase cuts cellobiose in half, producing two glucose molecules. Figure 2 which β-glucosidase is at its maximum produces 255.6% more glucose than in Figure 1 with β-glucosidase at its minimum in 60 hours. |

| - | + | The concentration of cellobiose in Figure 1 keeps low. This is because there is little cellulose converted to cellobiose by Exo/endo-glucanase. Also, if there is any cellobiose, they are all converted to glucose by β-glucosidase. | |

| - | [[File: | + | [[File:Edinburgh_semilogx3.png|thumb|center|700px| Figure 3: Graph of cellulose degradation over time with maximum β-glucosidase.<br/> Initial conditions: Cellulose - 100 g/kg, Glucose - 0.01 g/kg , Cellobiose - 0.01 g/kg. <br/> |

| - | Enzymes: Exo/endo-glucanase - | + | Enzymes: Exo/endo-glucanase - 1 g/kg, β-glucosidase - 0.01 g/kg <br/> Temperature 35° C. The x-axis is set to semilog.]] |

| - | Figure 3 is under the same conditions as Figure | + | Figure 3 is under the same conditions as Figure 2, but its x-axis is set to a semilog scale to illustrate what happens over a longer period of time. The effect of high β-glucosidase can better be seen with the complete conversion of cellobiose to glucose. |

| + | |||

| + | (We'd like to thank the ETH Zurich team for submitting some bugfixes to the simulation that led to this figure; where previously it violated the laws of physics, now it does not!) | ||

==Download MATLAB file== | ==Download MATLAB file== | ||

Latest revision as of 20:05, 28 October 2011

Cellulases (MATLAB model)

MATLAB is a general-purpose mathematical tool, developed by [http://www.mathworks.com Mathworks], and commonly used by engineers. Among other things, it can be used to solve ordinary differential equations (ODEs) by numerical integration.

An attempt was made to use MATLAB to model the degradation of cellulose into glucose in a biorefinery. But accurately predicting how much is converted in the synergistic system (where enzymes are kept close together) is difficult without literature to provide the ODEs and the kinetic parameters. Therefore this model only looks at the free floating (non-synergistic) enzyme approach. It is deterministic and is set by a series of initial conditions.

Contents |

Assumptions

The mathematical model is based on the ODEs and kinetic parameters outlined in [http://onlinelibrary.wiley.com/doi/10.1021/bp034316x/full Kadam et al (2004)]. The following are its assumptions and basis:

- Underlying assumption: cellulose, cellobiose, and glucose concentrations change continuously with time.

- Rate equations assume enzyme adsorption follows the Langmuir isotherm model.

- Glucose and cellobiose, which are the products of cellulose hydrolysis, are assumed to "competitively inhibit enzyme hydrolysis".

- All reactions are assumed to follow the same temperature dependency Arrhenius relationship (shown below). However, in reality it should be different for every enzyme component, "because of their varying degrees of thermostability, with β-glucocidase being the most thermostable. Hence the assumption is a simplification of reality".

- Conversion of cellobiose to glucose follows the Michaelis-Menten enzyme kinetic model.

Equations

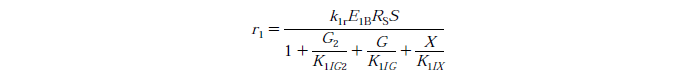

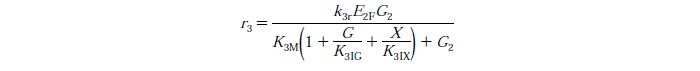

Rate Equations

Constants

- knr — reaction rate constant for reaction n

- EnB — the bound concentration for exo and endo-β-1,4-glucanase for reaction n

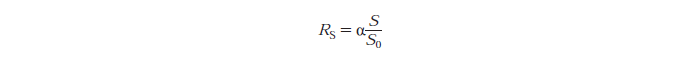

- Rs — substrate reactivity parameter

- S — substrate reactivity at a given time (g/kg)

- G2 — concentration of cellobiose

- G — concentration of glucose

- X — xylose concentration

- KnIG2 — inhibition constant for cellobiose at reaction n

- KnIG — inhibition constant for glucose at reaction n

- KnIX — xylose inhibition constant for reaction n

Note: For simplicity's sake we have assumed no xylose in the system, therefore X=0.

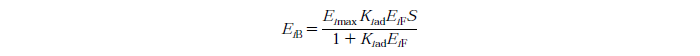

Langmuir Isotherm

Constants

- exo and endo-β-1,4-glucanase, i=1

- β-glucosidase, i=2

- Eimax — Maximum mass of enzyme that can be absorbed onto a unit of mass substrate

- Kiad — Dissociation constant for enzyme i

- EiF — Free enzyme concentration for enzyme i

- S — Substrate reactivity at a given time (g/kg)

Mass Balances

Arrhenius Equation

Constants

- Kir — Reaction rate constant of reaction i

- Eai — Activation energy of reaction i

- R — Universal gas constant

Construction of Model

The model was constructed using the numerical programme MATLAB. A script file was generated which holds the variable dictionary, constants, temperature dependency equations, the "ODE45" differential equation solver, and the plot command.

A separate function file to the script is created as script files can only operate on the variables that are coded into their m-files. Rs (the substrate reactivity parameter) changes at every iteration because it is dependent on the S the substrate concentration at a given time, the substrate being cellulose. Therefore S at the first iteration is S0, the initial substrate concentration. At the second iteration S is the previous value calculated by the ODE, and so on. After each step the new value of S is fed into the function file and is used for calculating the reaction rate constant for cellobiose and glucose, etc.

ODE45 calls on the function file to calculate the rate equations and then substitute them into the respective mass balance. A numerical integration is performed and the results can be seen below. ODE45 is used as it is more accurate than other solvers [http://www.mathworks.co.uk/help/techdoc/ref/ode23.html (according to Mathworks)]. It is based on an explicit Runge-Kutta formula and is a one-step solver.

Results

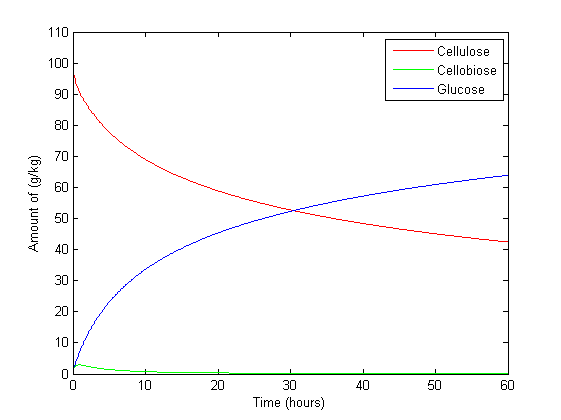

Figure 1 is set with β-glucosidase at its maximum concentration and Figure 2 with Exo/endo-glucanase at maximum. This is to compare the effect of certain enzymes on cellulose degradation and glucose production. The result is consistent with what is expected. Exoglucanase chews away at the end of a cellulose chain, producing cellobiose sugars and endoglucanase cuts cellulose chanins in the centre, turning one chain into two. This concurs with the results, with Figure 1 modelling markedly higher amount of cellulose at the minimum amount of exo/endo-glucanase than that of Figure 2. Whereas β-glucosidase cuts cellobiose in half, producing two glucose molecules. Figure 2 which β-glucosidase is at its maximum produces 255.6% more glucose than in Figure 1 with β-glucosidase at its minimum in 60 hours.

The concentration of cellobiose in Figure 1 keeps low. This is because there is little cellulose converted to cellobiose by Exo/endo-glucanase. Also, if there is any cellobiose, they are all converted to glucose by β-glucosidase.

Figure 3 is under the same conditions as Figure 2, but its x-axis is set to a semilog scale to illustrate what happens over a longer period of time. The effect of high β-glucosidase can better be seen with the complete conversion of cellobiose to glucose.

(We'd like to thank the ETH Zurich team for submitting some bugfixes to the simulation that led to this figure; where previously it violated the laws of physics, now it does not!)

Download MATLAB file

You can download the ready model as a .zip file:

References

- Kadam KL, Rydholm EC, McMillan JD (2004) [http://onlinelibrary.wiley.com/doi/10.1021/bp034316x/full Development and Validation of a Kinetic Model for Enzymatic Saccharification of Lignocellulosic Biomass]. Biotechnology Progress 20(3): 698–705 (doi: 10.1021/bp034316x).

"

"