Team:UCL London/Manufacturing/PurityYieldCost/ProcessDetails

From 2011.igem.org

(Difference between revisions)

| Line 5: | Line 5: | ||

<div id="content"> | <div id="content"> | ||

<h1>Process Details</h1> | <h1>Process Details</h1> | ||

| + | Hence, based on the market research,<br /> | ||

| + | The amount of product needed to meet the market requirement<br />= 1,000,000 treatments per yr × 0.005g per treatment = 5 kg per year<br /> | ||

| + | Assume: 20 batches per year<br /> | ||

| + | Final product yield per batch = 5 kg/20 = 0.25 kg | ||

| + | |||

[[File:Ucl-content-Manufacturing-flow.jpg|center]]<br /> | [[File:Ucl-content-Manufacturing-flow.jpg|center]]<br /> | ||

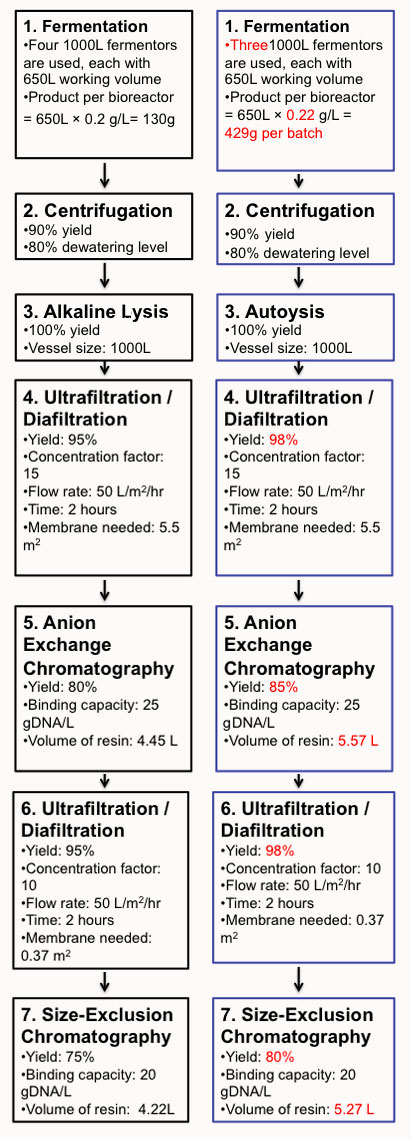

'''Figure 1.''' Comparison between the Current and Novel Bioprocesses.<br /> | '''Figure 1.''' Comparison between the Current and Novel Bioprocesses.<br /> | ||

Revision as of 22:03, 21 September 2011

Process Details

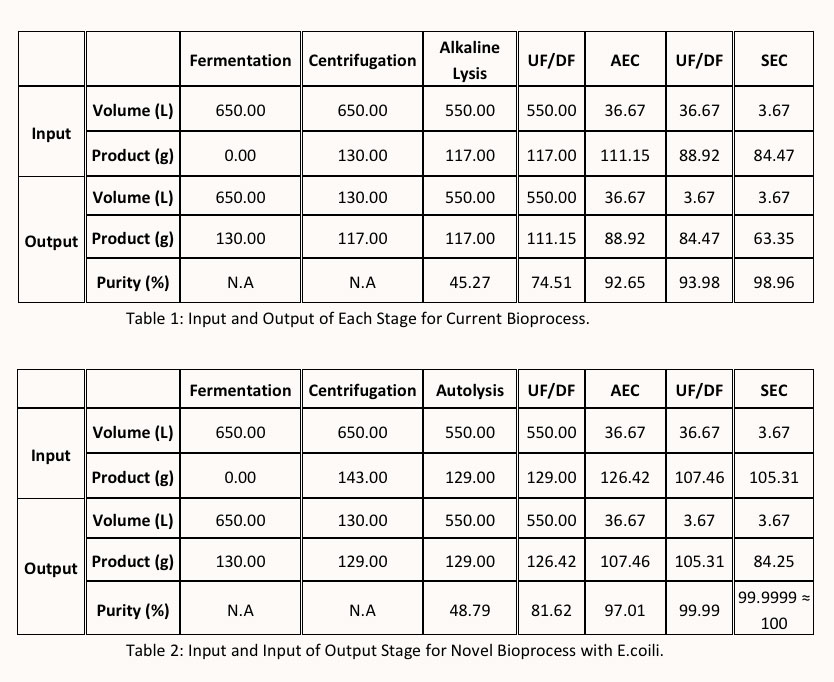

Hence, based on the market research,

The amount of product needed to meet the market requirement

= 1,000,000 treatments per yr × 0.005g per treatment = 5 kg per year

Assume: 20 batches per year

Final product yield per batch = 5 kg/20 = 0.25 kg

Figure 1. Comparison between the Current and Novel Bioprocesses.

Left: Flow Sheet of Current DNA Vaccine Manufacturing Process

Right: Flow Sheet of Novel DNA Vaccine Manufacturing Process with E.coili

Figure 1. Comparison between the Current and Novel Bioprocesses.

Left: Flow Sheet of Current DNA Vaccine Manufacturing Process

Right: Flow Sheet of Novel DNA Vaccine Manufacturing Process with E.coili

"

"