Team:Washington/Alkanes/Methods

From 2011.igem.org

| Line 4: | Line 4: | ||

=Introducing the PetroBrick= | =Introducing the PetroBrick= | ||

| - | [[Image:Washington_2011_PetroBrick.png|220px|frameless|border|link=http://partsregistry.org/wiki/index.php?title=Part:BBa_K590025|left]] | + | [[Image:Washington_2011_PetroBrick.png|220px|frameless|border="2"|link=http://partsregistry.org/wiki/index.php?title=Part:BBa_K590025|left]] |

| - | :: | + | <div style="position: left: 255px;"> |

| - | + | In order to produce alkanes, we need both acyl-ACP reductase (AAR) and aldehyde decarbonylase (ADC) to work together in the cell. In order to achieve this goal, we used standard cloning methods to construct a Biobrick that contained both AAR and ADC under a high constitutive promoter, each with it's own Elowitz standard RBS. This construct successfully synthesized our target product, and thus we have created a new modular alkane-producing platform: | |

| - | + | the <font size="5" weight=bold>PetroBrick.</font></div> | |

| - | = | + | <div style="position: relative;"> |

| - | + | [[Image:Washington2011_PetroBrick_Construct.png|730px|frameless|border|left|link=http://partsregistry.org/wiki/index.php?title=Part:BBa_K590025]] | |

| - | =Alkane Extraction= | + | =Alkane Production & Extraction= |

| - | + | After we had the complete gene assembly in our hands, the next step was to transform it into cells and start them growing for alkane production. We let them grow in 37 degree shaker for 48-72 hours, in sealed glass tubes. After the cells have gone through the alkane production process, the next step is to extract the alkanes out of the cell broth. We add acyl acetate directly into the glass test tube for cell growth. Then we vortex untill to everything is well mixed, to make sure all of the alkanes go directly into the ethyl acetate solvent. Next, we spin down the mixture by using a centrifuge at full speed to form three layers (cell pellet, media, and ethyl acetate supernatant). We use only the ethyl acetate layer to send for GCMS analysis. | |

| - | After the cells have gone through the alkane production process, the next step is to extract | + | |

| + | [[File:Washington_Alkane_extraction.png|right|400px|thumb|Diagram showing the process of extraction.]] | ||

=Alkane Detection= | =Alkane Detection= | ||

Explain GCMS... again basically graphics from presentation with text | Explain GCMS... again basically graphics from presentation with text | ||

| + | |||

| + | |||

| + | [[File:Washington 2011 GCMS slide.png|right|400px|thumb|Analyzing alkane production with GCMS.]] | ||

| + | |||

| + | |||

| + | </div> | ||

Revision as of 02:06, 17 September 2011

Introducing the PetroBrick

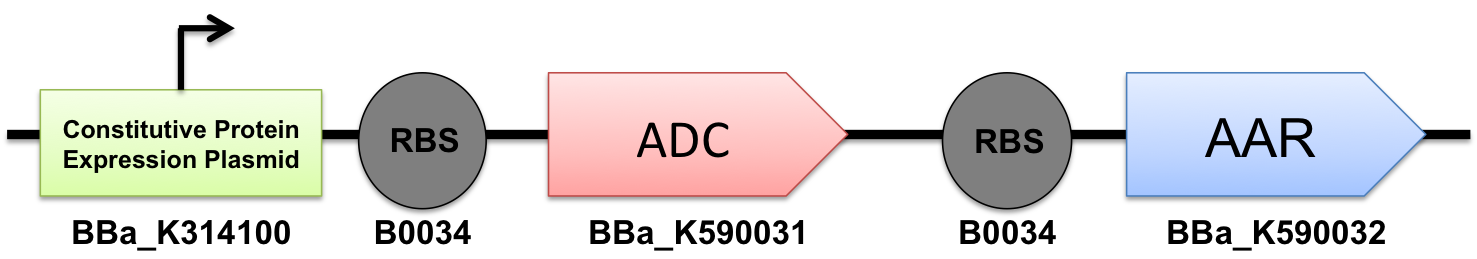

In order to produce alkanes, we need both acyl-ACP reductase (AAR) and aldehyde decarbonylase (ADC) to work together in the cell. In order to achieve this goal, we used standard cloning methods to construct a Biobrick that contained both AAR and ADC under a high constitutive promoter, each with it's own Elowitz standard RBS. This construct successfully synthesized our target product, and thus we have created a new modular alkane-producing platform:

Alkane Production & Extraction

After we had the complete gene assembly in our hands, the next step was to transform it into cells and start them growing for alkane production. We let them grow in 37 degree shaker for 48-72 hours, in sealed glass tubes. After the cells have gone through the alkane production process, the next step is to extract the alkanes out of the cell broth. We add acyl acetate directly into the glass test tube for cell growth. Then we vortex untill to everything is well mixed, to make sure all of the alkanes go directly into the ethyl acetate solvent. Next, we spin down the mixture by using a centrifuge at full speed to form three layers (cell pellet, media, and ethyl acetate supernatant). We use only the ethyl acetate layer to send for GCMS analysis.

Alkane Detection

Explain GCMS... again basically graphics from presentation with text

"

"