Team:Wageningen UR/Project/Devices

From 2011.igem.org

(→Fluid device designed by Team Wageningen UR to measure oscillations) |

(→Fluid device designed by Team Wageningen UR to measure oscillations) |

||

| Line 28: | Line 28: | ||

{{:Team:Wageningen_UR/Templates/Style | text= __NOTOC__ | {{:Team:Wageningen_UR/Templates/Style | text= __NOTOC__ | ||

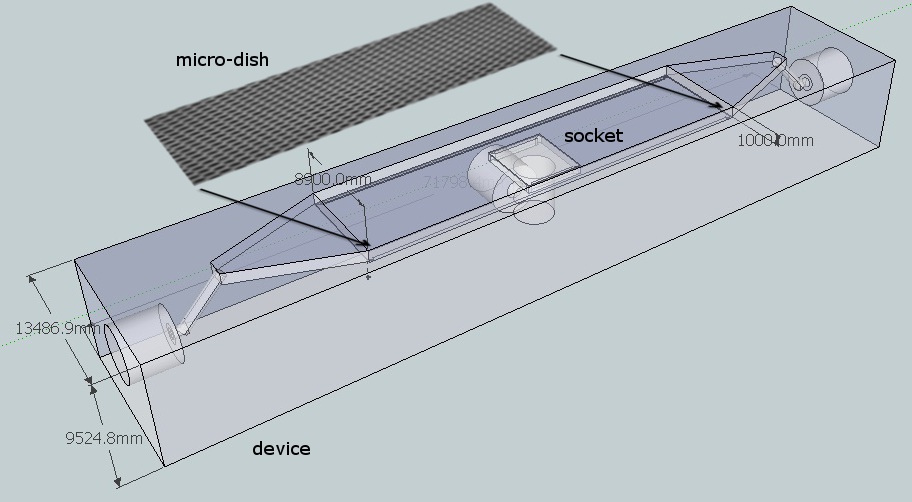

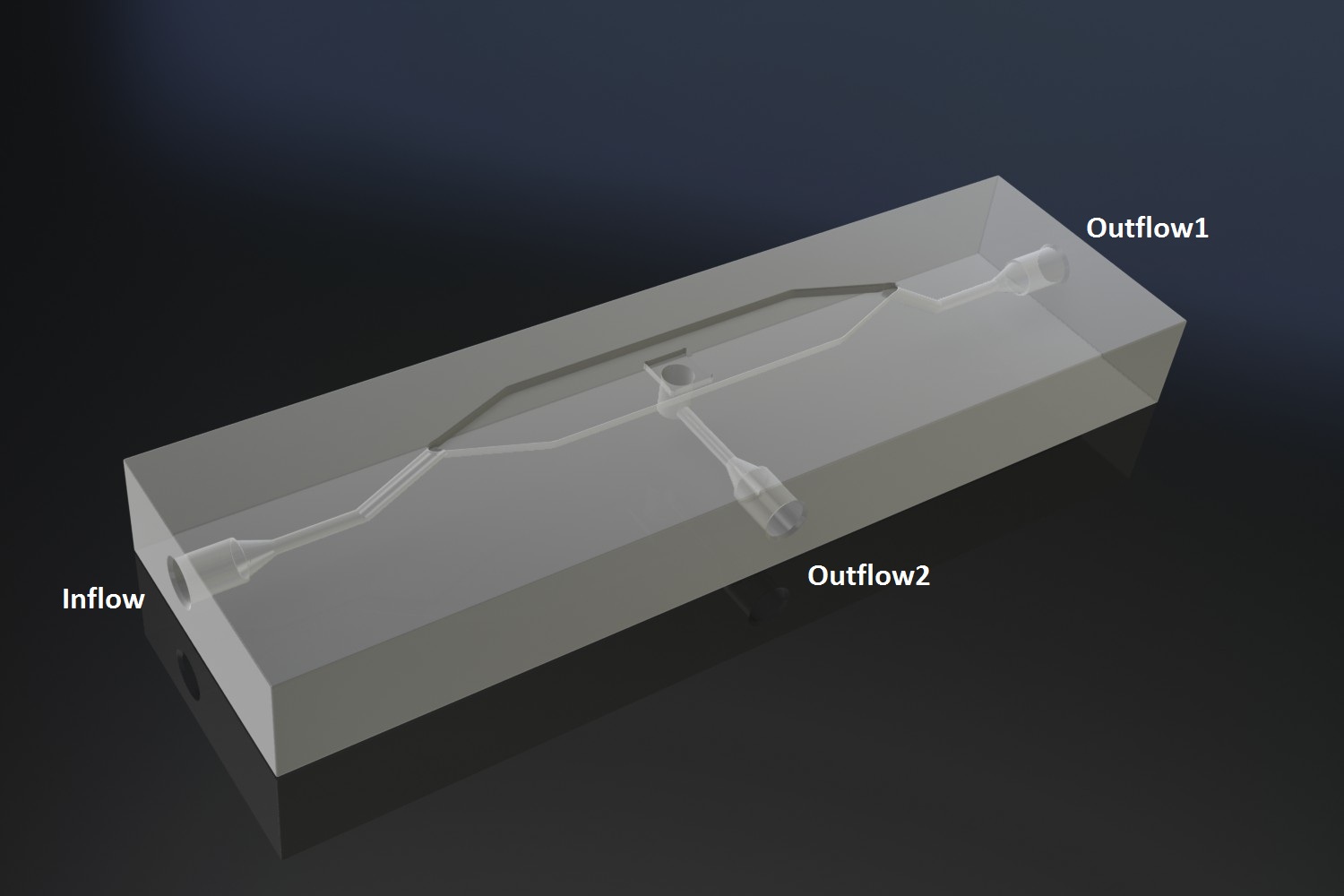

| - | The [http://www.nature.com/nature/journal/v463/n7279/abs/nature08753.html paper] our system is based on used microfluidic devices to measure oscillations. Such microfluidic devices however are very expensive and our iGEM team budget was limited, so we decided to design a customary fluidic device, which was produced in the Wageningen University workshop. To keep as many options as possible open, the idea | + | The [http://www.nature.com/nature/journal/v463/n7279/abs/nature08753.html paper] our system is based on used microfluidic devices to measure oscillations. Such microfluidic devices however are very expensive and our iGEM team budget was limited, so we decided to design a customary fluidic device, which was produced in the Wageningen University workshop. To keep as many options as possible open, the design implemented the idea that the device can potentially accommodate two bacteria growing platforms, a micro-sieve and a micro-dish. Gaining mor in-depth understanding of our system, we decided to focus on the micro-dish as platform to test the oscillatory behaviour of our construct. Figure 1 and 2 below show the the flow chamber as original scetch designed by our team and the 3D rendered depiction of the final device. |

| Line 35: | Line 35: | ||

| - | '''Fig.1 | + | '''Fig.1:''' ''Micro-sieve design original scetch and 3D render'' |

| + | |||

| + | The micro-dish contains porous wells, in which the cells can be physically constrained. It is placed in the socket of the dish, which allows a fluid to be flown over the wells. This fluid can be used to supply the cells with nutrients and wash away excess AHL and cells if necessary. | ||

| + | |||

| + | [[File:Production_device_WUR.jpg|200px]] | ||

| + | ''' Fig.2:''' ''Production of the device in the Wageningen University workshop'' | ||

}} | }} | ||

| Line 42: | Line 47: | ||

<!-- | <!-- | ||

| - | + | [[File:Closeup_device_WUR.JPG|200px]][[File:Setup_WUR.jpg|200px]] | |

| - | + | ||

| - | + | ||

| - | [[File:Closeup_device_WUR.JPG|200px | + | |

| - | + | ||

| - | + | ||

| - | [[File:Setup_WUR.jpg|200px | + | |

| Line 58: | Line 57: | ||

[[File:mouse_WUR.jpg|200px|center]] | [[File:mouse_WUR.jpg|200px|center]] | ||

| + | |||

Revision as of 21:54, 16 September 2011

"

"