Team:Edinburgh/Cellulases (MATLAB model)

From 2011.igem.org

(Difference between revisions)

| Line 25: | Line 25: | ||

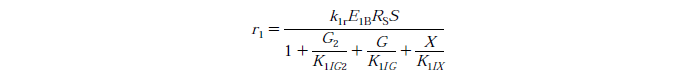

===Rate Equations=== | ===Rate Equations=== | ||

| - | [[File: | + | [[File:Edinburgh-Rate-1.png|thumb|center|500px|Endoglucanase digests cellulose chains]] |

Revision as of 11:17, 6 September 2011

Cellulases (MATLAB model)

The most important part of the biorefinery is the reactor where cellulose is converted to glucose. But accurately predicting how much is converted, using synergy between enzymes is difficult without literature to provide the ordinary differential equations (ODE's) and the kinetic parameters. Therefore this model only looks at the free floating enzyme approach (non-synergy). It is deterministic i.e non random and is set by a series of initial conditions.

Contents |

Assumptions

The mathematical model is based on the ODE's and kinetic parameters outlined in [http://onlinelibrary.wiley.com/doi/10.1021/bp034316x/full Kadam et al, 2004]. The following are its assumptions and basis:

- Rate equations assume enzyme adsorption follows the Langmuir isotherm model

- Glucose and cellobiose which are the products of cellulose hydrolysis, were assumed to, 'competitively inhibit enzyme hyrolysis' [http://onlinelibrary.wiley.com/doi/10.1021/bp034316x/full Kadam et al, 2004]

- Assume all reactions follow the same temperature dependency Arrhenius relationship. However it should be different for every enzyme component, 'because of their varying degrees of thermostability, with beta-glucocidase being the most thermostable. Hence the assumption is a simplification of reality' [http://onlinelibrary.wiley.com/doi/10.1021/bp034316x/full Kadam et al, 2004]

- Conversion of cellobiose to glucose follows the Michaelis-Menten enzyme kinetic model

Equations

Rate Equations

References

- Kadam KL, Rydholm EC, McMillan JD (2004) [http://onlinelibrary.wiley.com/doi/10.1021/bp034316x/full Development and Validation of a Kinetic Model for Enzymatic Saccharification of Lignocellulosic Biomass]. Biotechnology Progress 20(3): 698–705 (doi: 10.1021/bp034316x).

"

"