Team:Wageningen UR/Project/Devices

From 2011.igem.org

(→Fluid device designed by Team Wageningen UR to measure oscillations) |

(→Fluid device designed by Team Wageningen UR to measure oscillations) |

||

| Line 34: | Line 34: | ||

[[File:Scetch device WUR.jpg|400px]] [[File:Module-2 WUR.JPG|333px]] | [[File:Scetch device WUR.jpg|400px]] [[File:Module-2 WUR.JPG|333px]] | ||

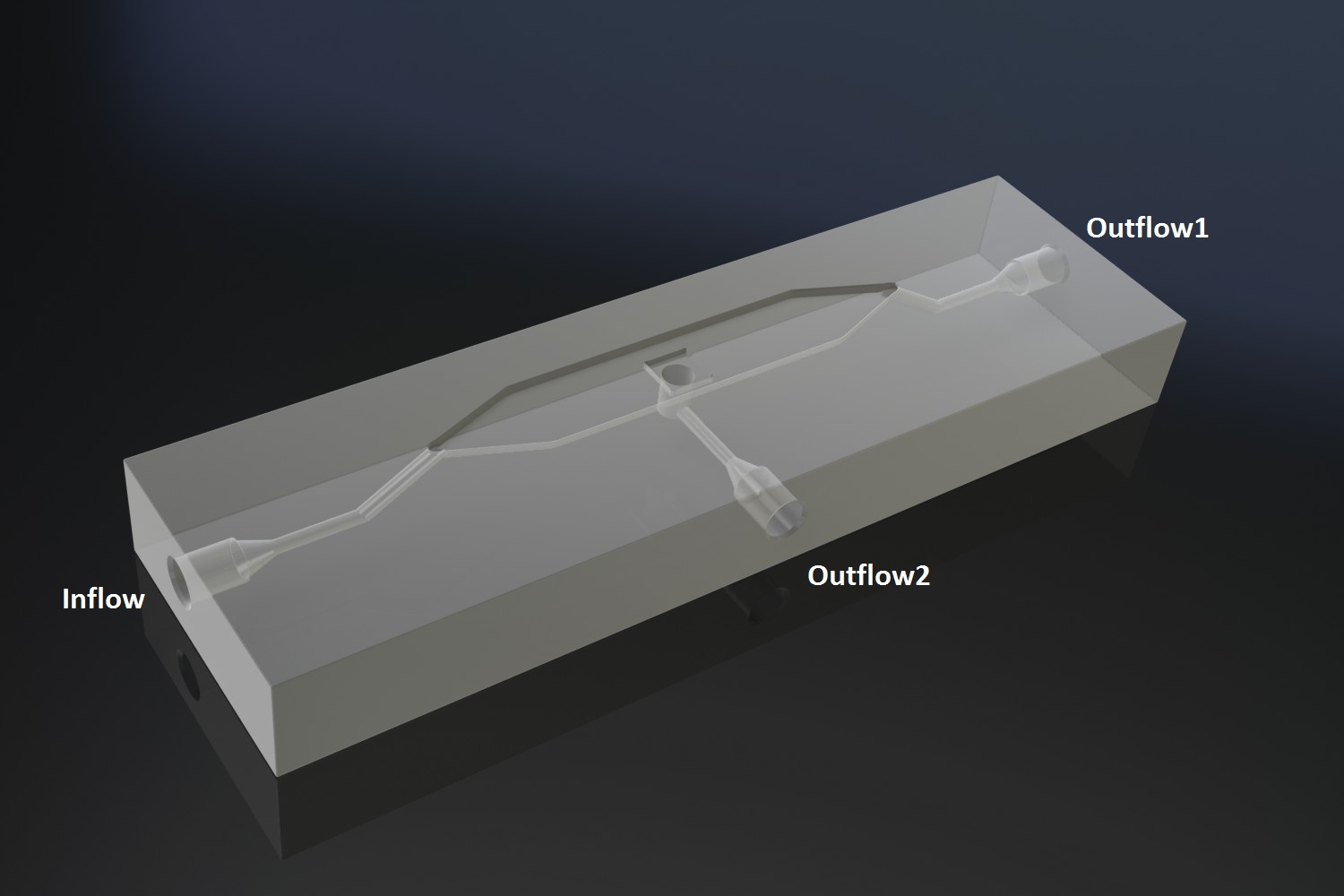

| + | '''Fig.1:''' ''Micro-sieve design: original scetch and 3D render'' | ||

| - | + | The micro-dish contains porous wells, in which the cells can be physically constrained. It is placed in the socket of the dish, which allows a fluid to be flown over the wells. This fluid can be used to supply the cells with nutrients and wash away excess AHL and cells if necessary. Figure 2 shows a schematic of the device. The inflow and outflow1 can be used to flush the device with fresh medium. The use of outflow2 depends on the bacteria growing platform. In the case of the micro-sieve it can be used to create an under pressure, e.g. with a syringe, to trap the bacteria on the sieve. T | |

| - | + | ||

| - | The micro-dish contains porous wells, in which the cells can be physically constrained. It is placed in the socket of the dish, which allows a fluid to be flown over the wells. This fluid can be used to supply the cells with nutrients and wash away excess AHL and cells if necessary. | + | |

[[File:Production_device_WUR.jpg|200px]] | [[File:Production_device_WUR.jpg|200px]] | ||

Revision as of 22:08, 16 September 2011

"

"