Team:Wageningen UR/Project/Devices

From 2011.igem.org

(→Customary fluidic device designed by Team Wageningen UR to measure oscillations) |

Matthijnwur (Talk | contribs) (→Custom fluidic device designed by Team Wageningen UR to measure oscillations) |

||

| Line 26: | Line 26: | ||

==== Design ==== | ==== Design ==== | ||

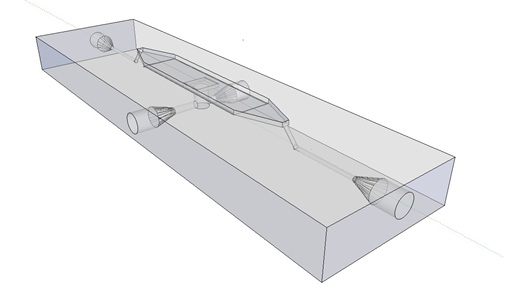

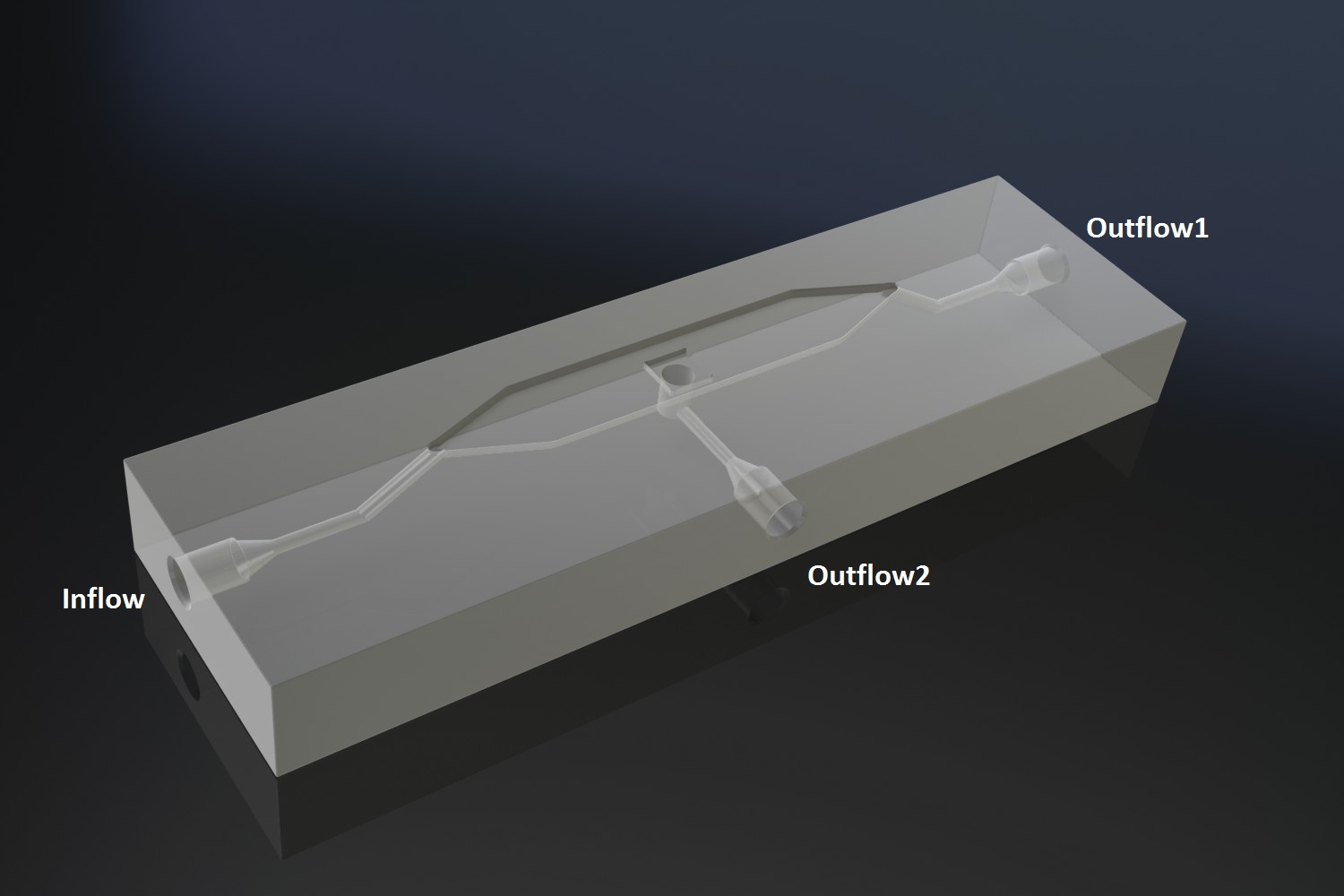

| - | The [http://www.nature.com/nature/journal/v463/n7279/abs/nature08753.html paper] | + | The [http://www.nature.com/nature/journal/v463/n7279/abs/nature08753.html paper] oscillatory system is based on, used microfluidic devices to physically constrain the host cells. This was necessary to induce and monitor oscillatory behaviour of a population of e.coli cells. Such microfluidic devices are very expensive and only usable for one experiment. Due to this we set out to find a cheap alternative for these microfluidic devices. Eventually we designed our own flow device, of which the design is seen in figure 1. |

| + | |||

| + | [[File:mainpic.jpg]] | ||

| + | |||

| + | '''Fig.1:''' ''Wire frame model of designed flow device.'' | ||

| + | |||

| + | '''Bacterial growing platforms''' | ||

| + | |||

| + | This flow device can accommodate two bacterial growing platforms, a micro-sieve and a micro-dish. The micro-sieve as depicted is figure .. are membranes which have evenly distributed pores of 200 nm in diameter. These membranes are used in dairy industry to sterilise dairy products by removing micro-organism through filtration. Through filtration a cake of cells will form on the membrane, potentially giving us a platform capable of inducing and giving a mean of monitoring oscillatory behaviour of a population of e. coli cells. | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| Line 32: | Line 70: | ||

[[File:Scetch device WUR.jpg|400px]] [[File:Module-2 WUR.JPG|333px]] | [[File:Scetch device WUR.jpg|400px]] [[File:Module-2 WUR.JPG|333px]] | ||

| - | '''Fig.1:''' ''Design | + | '''Fig.1:''' ''Design flow device made in google sketchup'' |

Revision as of 19:35, 19 September 2011

"

"