Collaboration - Cell Viability in Tailings Pond Water

We were asked by the Calgary iGEM team to to test the viability of their chassis to survive in tailings pond water. If E. coli DH5α cells containing one of their constructs can grow normally in medium prepared with tailings water, we can be confident that the chassis can be applied to tailings pond water in general.

Materials and Methods

50 mL of LB medium was made with tailings water and filtered through MILLEX filter Unit GS MF-Millipore MCE Membrane 0.22 µm in order to sterilize it and appropriate antibiotics were added. The tailings LB was inoculated with E. coli DH5α cells containing BBa_K331009 to an OD600 of 0.1. The flask was incubated at 37˚C with shaking for 7 hours, during which photometric readings were taken every 30. Photometric readings were taken using the Pharmacia Biotech Ultrospec 3000, as the OD600 readings reached 1.0 the solutions was diluted with LB media to keep the OD600 reading between 0.1 and 1.0. The same protocol was used to observe cell growth of E. coli DH5α cells containing BBa_K331009 in 50 mL of LB medium made with MilliQ H2O.

Results

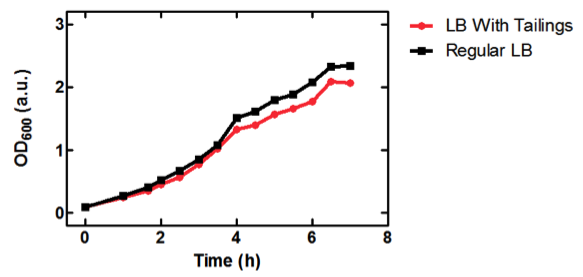

Figure 1. OD600 of E. coli DH5α cells containing BBa_K331009 cultured in LB medium made with tailings water (red) and LB medium made with MilliQ H2O (black). Performed by our team.

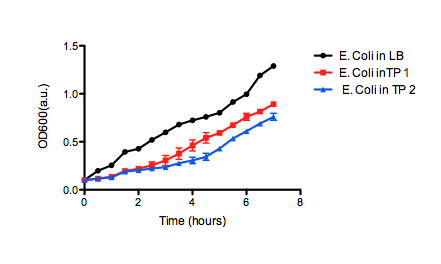

Figure 2. OD600 of E. coli DH5α cells containing BBa_K331009 cultured in LB medium made with tailings water (red and blue) and LB medium made with MilliQ H2O (black). Performed independently by the Calgary 2011 Team.

Conclusion

As seen in Figure 1, E. coli DH5α cells were able to grow in LB medium made with tailings water, suggesting that the chassis will survive for use in tailings pond water.

Attributions & Contributions

The University of Lethbridge iGEM team would like to acknowledge the following people for their attributions and expertise which added to the success of our project, it is greatly appreciated, and has helped us gain new knowledge and skills.

Dr. A. William Smith

The Department of New Media at the University of Lethbridge – For his assistance, knowledge, leadership and hard work, in the Biospirits film project.

Mr. Doug Bray

The Faculty of Arts and Science at the University of Lethbridge – For his training and guidance of team members in the use of transmission electron microscopy.

Dr. Mark Roussel

The Department of Chemistry and Biochemistry at the University of Lethbridge – For his assistance with protein modeling.

Mr. David Lain Huston and the Arnott Labs

The Institute of Cellular, Molecular, and Systems biology in Glasgow – For sending the team genes from the Xylene degradation pathway.

Wet Lab Work

We are proud to say that all wet lab work was accomplished by the undergraduate members of our iGEM team.

"

"