Team:Calgary/Project

From 2011.igem.org

| Line 19: | Line 19: | ||

<h2>The Toxicity of Naphthenic Acids</h2> | <h2>The Toxicity of Naphthenic Acids</h2> | ||

| - | <p>One of the major industry concerns with NAs is their contribution to corrosion in equipment and pipelines. In addition, their surfactant nature also makes them toxic in mammalian systems allowing them to pass through and potentially disrupt cell membranes. NAs with a higher molecular weight are typically less toxic than those with a lower molecular weight. These lower molecular weight compounds have been shown to have LC<sub>50</sub> values of less than 50 mg/L in freshwater systems. The higher the concentration of the NAs in the environment the greater the potential harm to the local ecosystem, in particular, their contamination of biological communities surrounding the tailings ponds.</p> | + | <p>One of the major industry concerns with NAs is their contribution to corrosion in equipment and pipelines. In addition, their surfactant nature also makes them toxic in mammalian systems allowing them to pass through and potentially disrupt cell membranes. NAs with a higher molecular weight are typically less toxic than those with a lower molecular weight. These lower molecular weight compounds have been shown to have LC<sub>50</sub> values of less than 50 mg/L in freshwater systems. The higher the concentration of the NAs in the environment the greater the potential harm to the local ecosystem, in particular, their possible contamination of biological communities surrounding the tailings ponds.</p> |

<br> | <br> | ||

Revision as of 21:40, 28 September 2011

A Biosensor for Naphthenic Acids

Naphthenic Acids in the Oil Sands

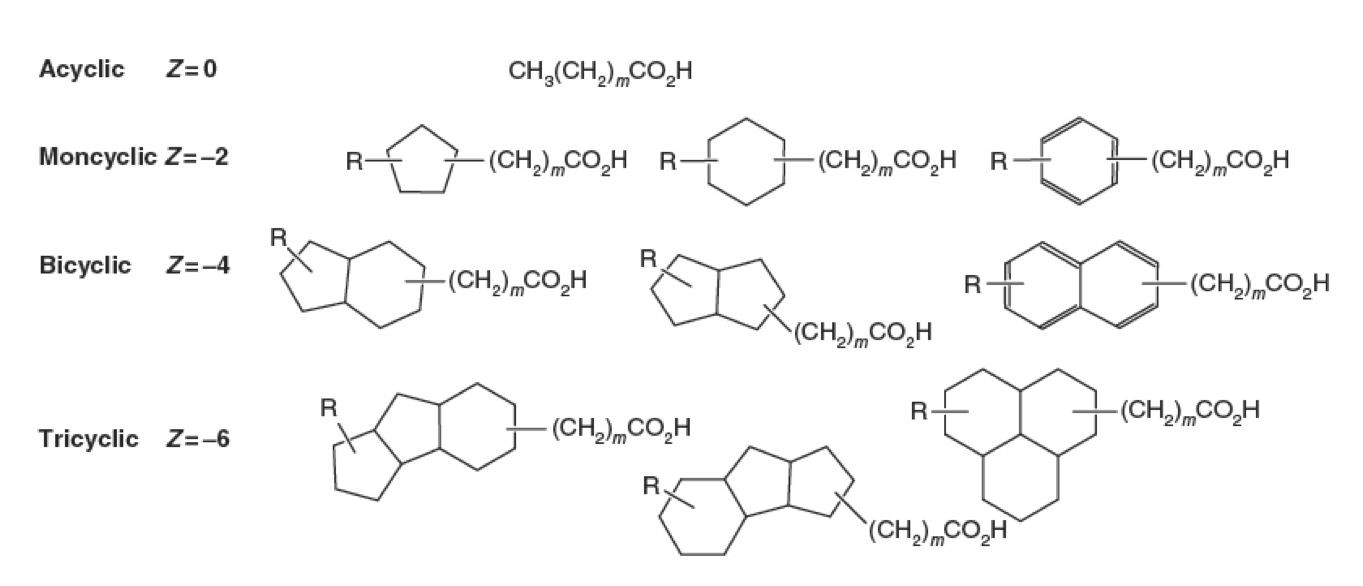

Naphthenic Acids (NAs) are a group of recalcitrant, hydrophobic, compounds which may contain a variety of structures. All naphthenic acids contain a conserved carboxylic acid group followed by a hydrocarbon chain. Attached to this hydrophobic chain can be between one and four hydrogenated ring systems. The classification of what defines a naphthenic acid has been of great debate in the scientific community; their diversity has contributed to difficulties targeting them for biodegradation. NAs are natively found in oil sands deposits and their surfactant quality aids in a higher efficiency of oil sands recovery in the hot water extraction process. The majority of NAs end up in large tailings ponds with a variety of other toxic by-products of bitumen extraction. The NAs continuously accumulate in these large tailings ponds and are allowed to settle to the bottom of these pools.

Bitumen Extraction Process

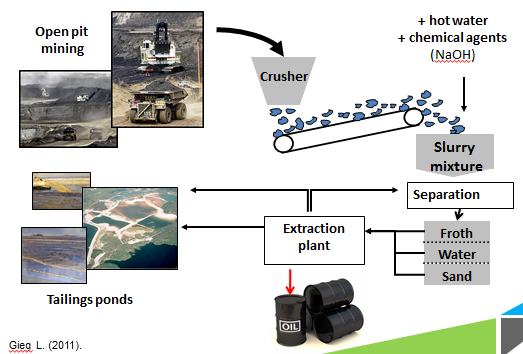

Naphthenic acids are found naturally in the bitumen that is extracted from the ground, but is not one of the desired products in refined petroleum. During the refining process, excess hot water and chemical agents such as NaOH are added to aid in the separation of contaminants such as naphthenic acids from the desired hydrocarbons. These contaminants are then stored in the tailings ponds that are shown above.

The Toxicity of Naphthenic Acids

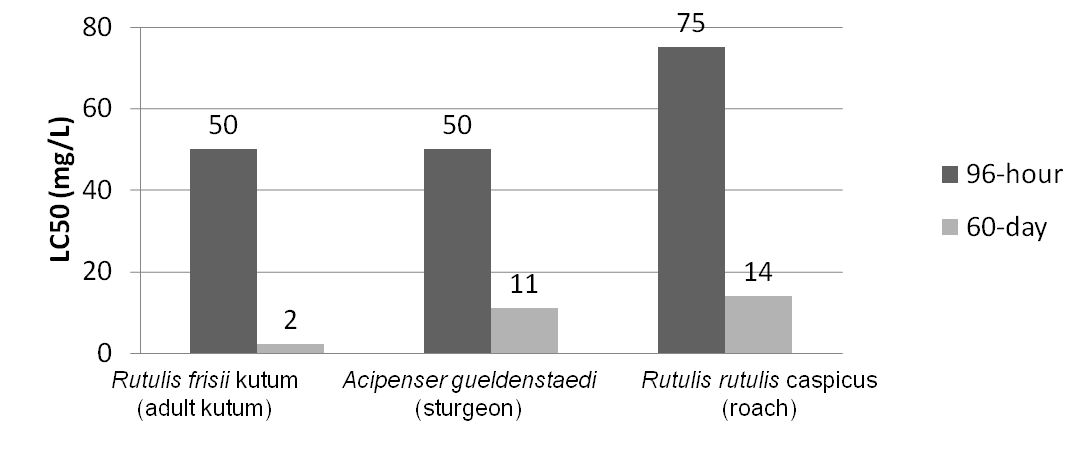

One of the major industry concerns with NAs is their contribution to corrosion in equipment and pipelines. In addition, their surfactant nature also makes them toxic in mammalian systems allowing them to pass through and potentially disrupt cell membranes. NAs with a higher molecular weight are typically less toxic than those with a lower molecular weight. These lower molecular weight compounds have been shown to have LC50 values of less than 50 mg/L in freshwater systems. The higher the concentration of the NAs in the environment the greater the potential harm to the local ecosystem, in particular, their possible contamination of biological communities surrounding the tailings ponds.

Monitoring Naphthenic Acids

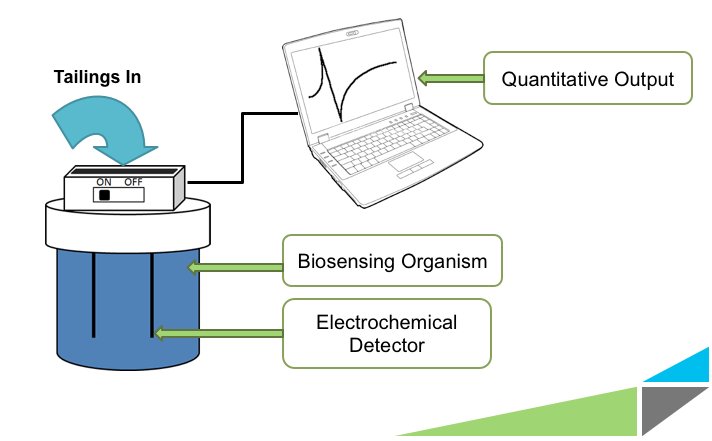

Having the ability to monitor the levels of NAs is mandated by Canadian law and would be useful in assessing whether or not any future detoxification or remediation efforts are effective. Other applications including examining the surrounding areas for seepage of NAs into ground water, and determining the extent of damage caused by oil based chemical spills. Currently, the only ways to test for the presence of NAs are mass spectrometry and gas chromatography. These methods are costly, require the experience of a trained technician, must be shipped to a facility to be processed, and takes up to several hours per analysis. The University of Calgary’s iGEM team is working on developing a novel electrochemical biosensor which would allow for cheap, quick, and convenient on site monitoring of NAs. The bacteria used to sense the naphthenic acids would be contained inside a device, and respond specifically to these compounds. Their response would signal a change in electrochemical potential in the solution which could be used as a read-out for our device in a quantitative manner.

Engineering the Biosensor

Engineering the biosensor involved three main components: finding an appropriate sensory element, characterizing a novel reporter and selecting and designing tools for an appropriate chassis for our system. Information on the sensory element can be found on our Promoter Project page. More details on our reporter can be found on the Reporter Project page. More details on our chassis can be found on our Chassis Project page.

"

"