Team:Cambridge/Experiments/Reflectin Thin Films II

From 2011.igem.org

Contents |

Reflectin Thin Films II

Thin films were produced after refining our earlier methods from reflectin thin films I during which we discovered some very interesting properties.

Practice

- Centrifugation of the solutions prior to coating to sediment insoluble impurities (13000rpm for 10 minutes). We hope to reduce the level of solid impurities.

- Introduction of liquid CO2 pressure wash for cleaning of silicon substrates. O2 plasma may have changed surface chemistry of the silicon, it is hoped physical cleaning will aid 'wetting' of the substrate providing a nice interface for subsequent coating.

- Trial spin coating on glass substrate to investigate the effect of different substrates and image of above and below lighting.

- Heat cured the thin films for varying amounts from couple of seconds to 30 minutes at 80oc

- Measured the reflectance spectra of some of the thin films to check colouration

- BSA (Bovine Serum Albumin) control to assess generic properties of proteinaceous thin films subject to the same coating conditions.

Results

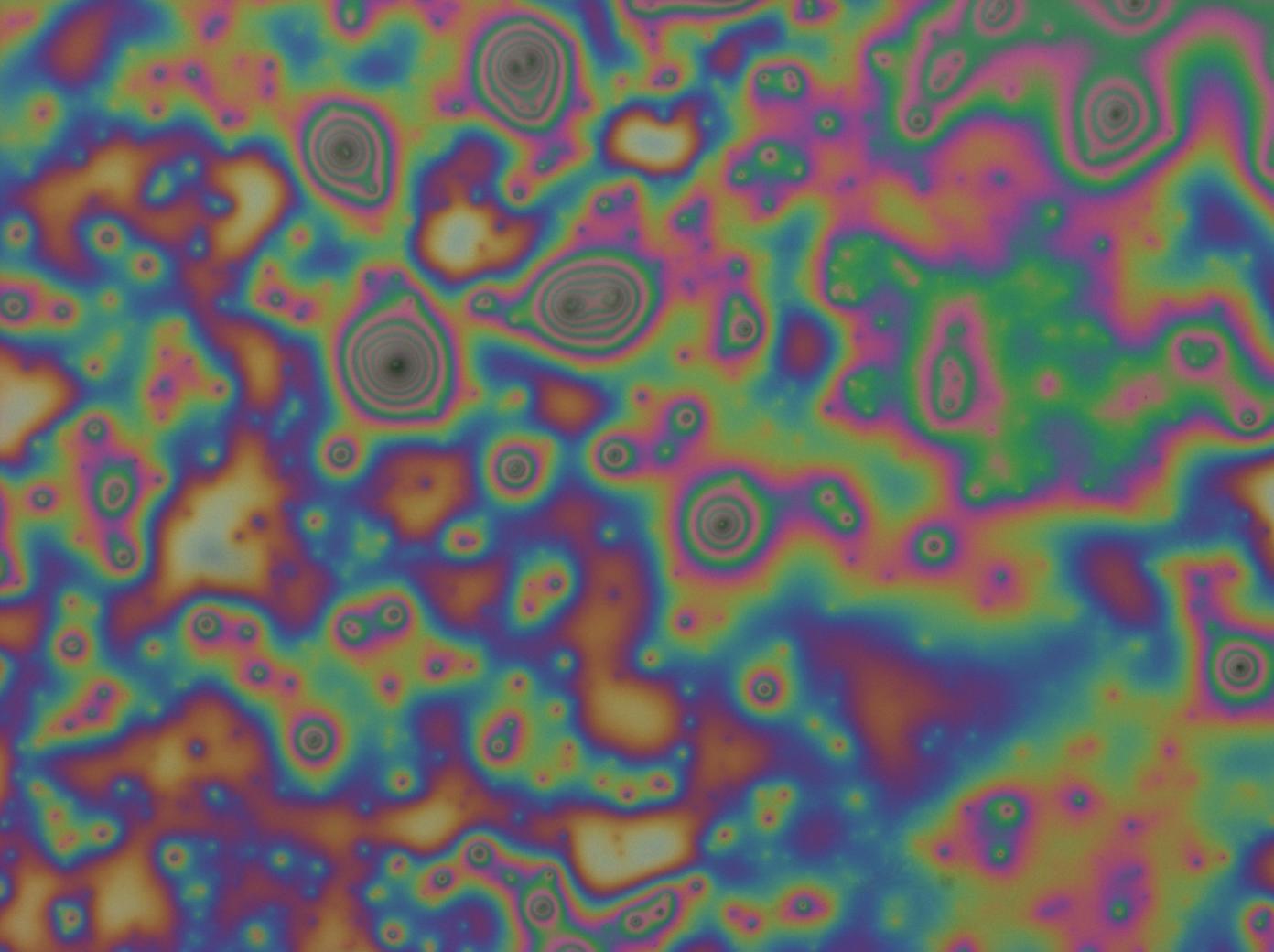

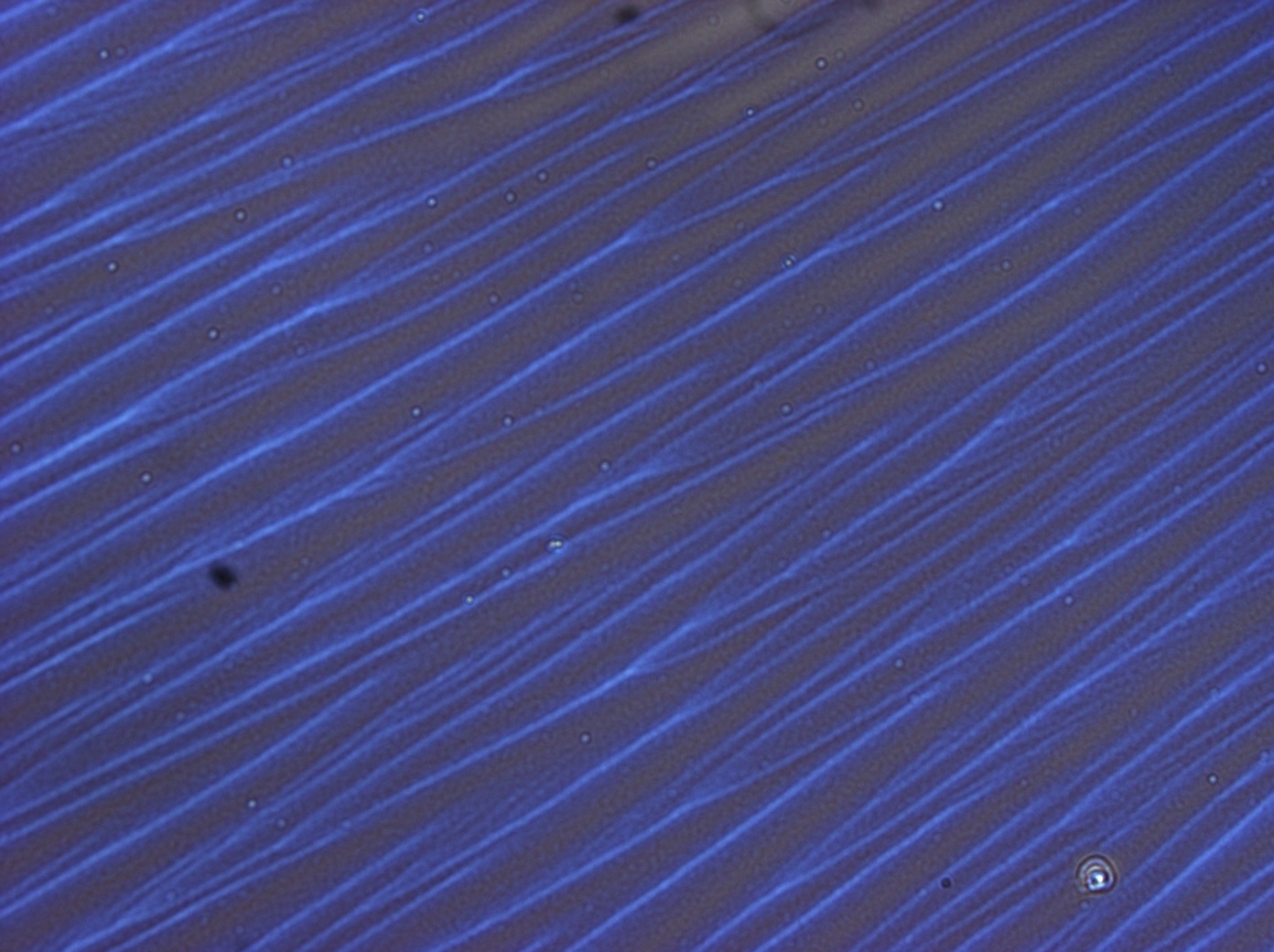

The result of centrifugation has led to dramatic differences in the spin-coated films. Below are shown typical results. The first image highlights the films produced on the first day whilst the second image highlights films produced using the refined protocol, finally the third image shows the BSA control produced using the refined protocol

This film shows mainly dark spots suggesting diffuse scattering and therefore solid impurities and great variations in colour, which implies a variation in film thickness and confirmed when we imaged them under the confocal microscope.

This film produced from the refined protocol demonstrates a much more uniform colour, dark blue in the bottom left fading to yellow in the top right. There are still numerous marks that suggest impurites or the possibility the films are not aggregating properly, but they are dominated by smooth blue and yellow regions.

The BSA control shows the films formed do not seem to demonstrate 'iridescence' than reflectin, though it does reflect a very discrete selection of wavelengths, mainly blue as opposed to the multicolours of reflectin films. There are however much less disruption in the form of impurities, most likely as the bovine serum albumin was purified industrially as opposed to the small scale methods we are implementing in the lab.

Further Observations and Conjecture

Summary

- The BSA control illustrates proteins being themselves polymers can be cast into thin films with differing physical properties therefore conclusions made with reflectin may equally apply to other proteins. As the dominant composition of reflectin are the unusually high amounts of sulphur and aromatic compounds it is advisable to perform controls with similarly unusual proteins of similar composition.

- Self-assembly crystallization behaviour is due to dehydration of films, subsequent application of water seemed to reverse the change whilst heating restored the crystallization albeit at a much slower speed than initially. This spontaneous phase separation requires further study in particular reproduction of the conditions under which it forms initially after spin/flow coating. However subsequent prolonged 'curing' seemingly stabilises the film. The crystallization may also be due to other factors like the amount of reflectin or presence of contaminants. Further investigations are required.

- Colour changes can be initiated by application of water and ethanol vapours consistent with thin-film interference and existing literature.

Safety

The new hazards identified with the changes are the liquid CO2 pressure washer and the hot plate. Dr Matthew Hawkeye performed all use with the pressure washer in the fume hood, whilst care was taken with the hot plate, using tweezers and wearing gloves to manipulate the hot substrates and allowing time to cool prior to mounting for microscopy.

"

"