Team:Cambridge/Experiments/Reflectin Thin Films I

From 2011.igem.org

Contents |

Reflectin Thin Films I

The aim of these experiments was to reproduce the flowcoating experiments reported in the literature and pioneer spincoating techniques in addition to performing controls to confirm that any properties of the films made were due to reflectin and not the solvent used in the preparation of the films.

Practice

The vacuum centrifuged protein was now visible as white pellets on the base of eppendorf tubes. This pellet was resuspended in HFIP before being spincoated or flowcoated onto silicon wafers or glass slides which were prepared as described in the Substrate Preparation Protocol.

Results

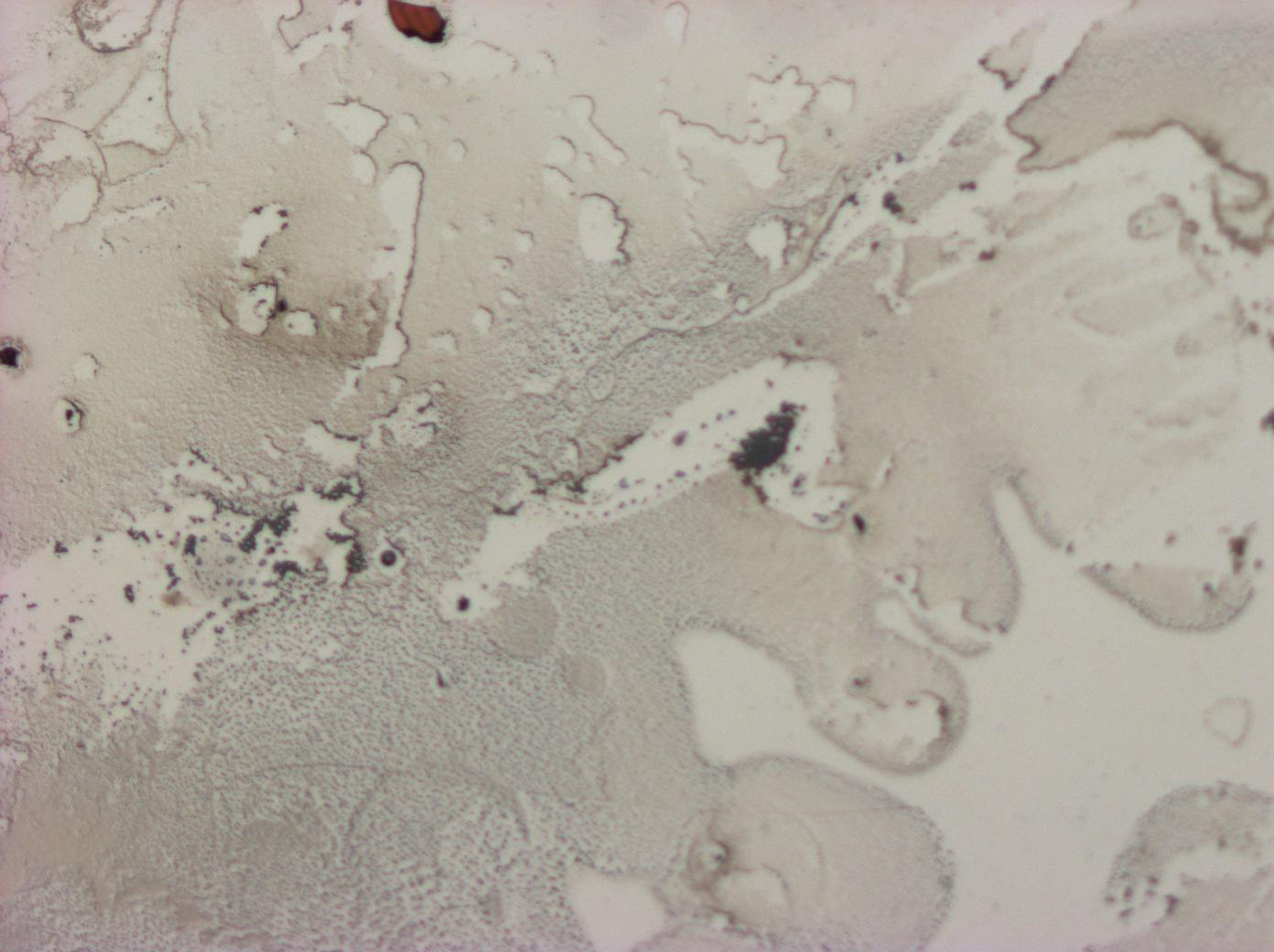

The first reflectin thin films produced some astounding colours, but were far from uniform. Dark objects can be seen in the centre of the regions that vary most in colour. This suggests that the height of the thin film is varying around these supposed impurities.

As a control we prepared a HFIP (solvent) only thin film - this produced a predominantly colourless, dirty smear, not a smooth colourful thin film.In summary, the first thin films do appear to display thin film interference effects, whereas the solvent alone does not. In order to move forward we altered the protocol with the aim of removing impurities from the reflectin solution (by centrifugation), we changed the substrate cleaning technique (CO2 pressure wash, in place of acetone bath and O2 plasma oven), and we decided to run a further control (Bovine Serum Albumin) in order to test if the effects we were seeing were unique to reflectin, or a feature of any proteinaceous thin film. See Reflectin Thin Films II for more details.

Safety

Safety considerations for the substrate preparation, flowcoating and spincoating techniques can be found on the relevant protocol pages. In general labcoat, safety glasses and nitrile safety gloves were worn throughout these three procedures, and all activities took place in the fume hood, except the splitting of the silicon substrate.

"

"