Team:Cambridge/Experiments/Reflectin Thin Films II

From 2011.igem.org

(Difference between revisions)

(→Results) |

|||

| Line 13: | Line 13: | ||

==Results== | ==Results== | ||

The centrifugation appears to have reduced the disruption due to impurities in the coated solution | The centrifugation appears to have reduced the disruption due to impurities in the coated solution | ||

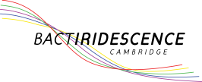

| - | [[File:Reflectin Thin Film3.jpg |thumb| | + | [[File:Reflectin Thin Film3.jpg |thumb|500px|left| Reflectin Thin Film made with protein/HFIP solution (not centrifuged]] |

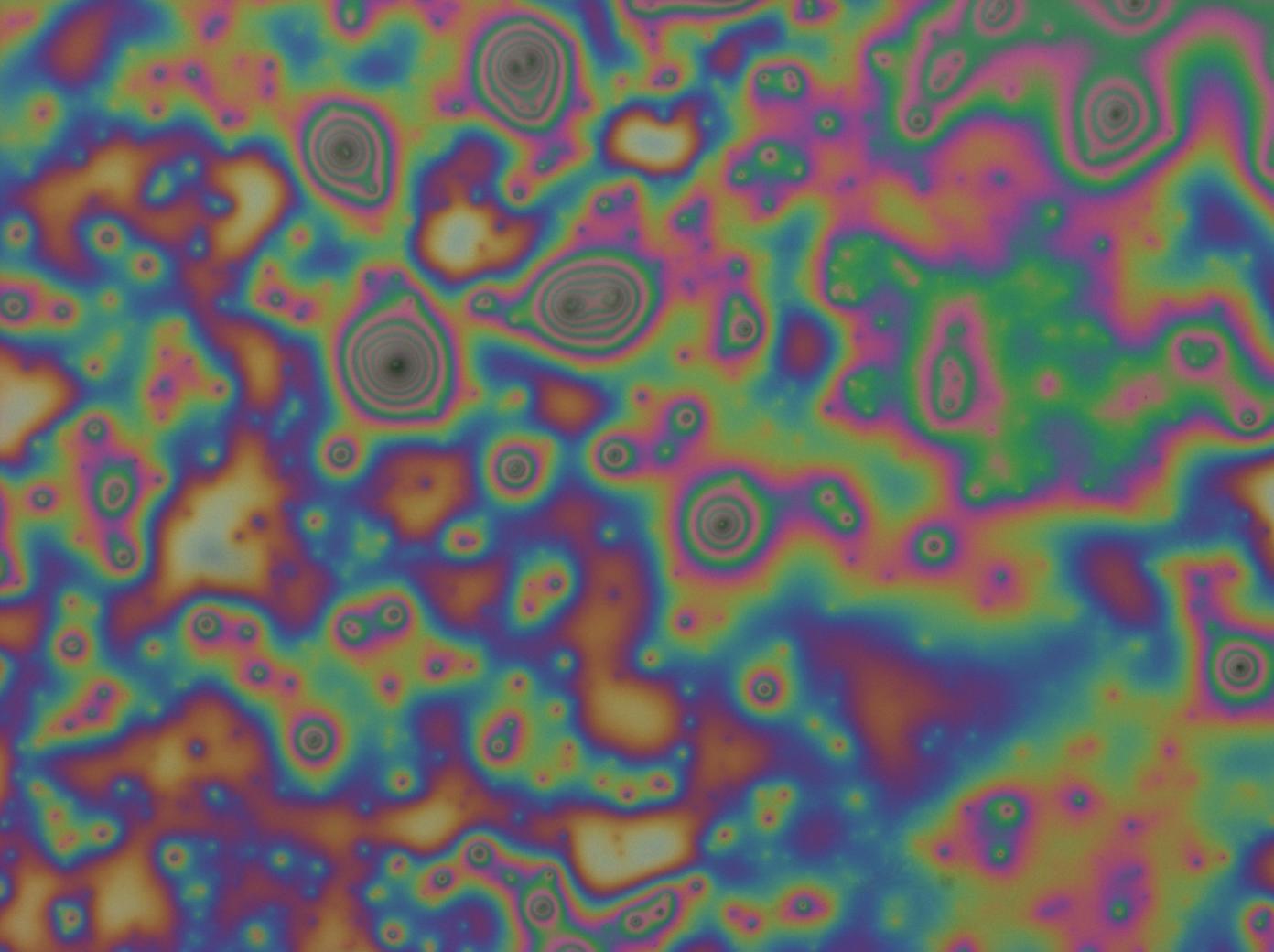

| - | [[File:Reflectin Thin Film 2.jpg |thumb| | + | [[File:Reflectin Thin Film 2.jpg |thumb|500px|left|Reflectin Thin Film made with centrifuged protein/HFIP solution]] |

| - | + | [[File:BSAcontrolfilm1.jpg |thumb|500px|left|Thin Film made with Bovine Serum Albumin/HFIP solution]] | |

| - | + | ||

| - | + | ||

| - | + | ||

==Safety== | ==Safety== | ||

{{Template:Team:Cambridge/CAM_2011_TEMPLATE_FOOT}} | {{Template:Team:Cambridge/CAM_2011_TEMPLATE_FOOT}} | ||

Revision as of 20:52, 28 August 2011

Loading...

Contents |

Reflectin Thin Films II

We refined our methods in a number of ways:

Practice

- Centrifugation of the solutions prior to spin and flow coating to sediment the impurities that caused thickness variations previously. (13000rpm for 10 minutes)

- We introduced liquid CO2 pressure wash to improve cleaning of the silicon substrates

- Trialled spin coating on a glass substrate to allow us to image the way the thin film refracts and transmits light.

- We heat cured the thin films, 10 minutes at 80 or 120 degrees.

- We recorded the reflectance spectra of some of the thin films

- We ran a control using the protein bovine serum albuimin.

Results

The centrifugation appears to have reduced the disruption due to impurities in the coated solution

Safety

"

"