Team:Cambridge/Safety

From 2011.igem.org

(→Do your project ideas raise biosafety issues?) |

|||

| (60 intermediate revisions not shown) | |||

| Line 1: | Line 1: | ||

{{Template:Team:Cambridge/CAM_2011_TEMPLATE_HEAD}} | {{Template:Team:Cambridge/CAM_2011_TEMPLATE_HEAD}} | ||

| - | + | =Safety= | |

| - | Safety is of utmost importance during projects involving synthetic biology. Not only must the welfare of | + | Safety is of utmost importance during projects involving synthetic biology. Not only must the welfare of scientific and non-scientific staff within the department be considered, but also that of the wider community. Safety procedures have been prioritised from the beginning of our project and we have taken care to pick a project that poses minimal biosafety risks even in the event of accidental release from a laboratory. |

| - | + | ==Do your project ideas raise biosafety issues?== | |

| - | + | We made a point of envisioning [[Team:Cambridge/Project/Conclusion | plans for future applications]] that do not rely on exposing the environment or the public to genetically modified organisms. Our project creates new systems that can be used within current biosafety guidelines, rather than relying on a significant shift in policy towards release of GM organisms. | |

| - | + | ||

| - | + | ===Public Safety=== | |

| - | working with | + | *Should an organism containing the reflectin production devices escape from the lab, we do not anticipate any significant hazards for the public since '''structural colour will not increase the host range of the host bacteria, nor alter its pathogenicity'''. |

| + | ===Environmental Safety=== | ||

| + | *Organisms with structural colour should interact with their environments in an identical way to those without, so '''there are no significant risks of environmental damage'''. We work with disabled strains which should be at a disadvantage in the natural environment and would not be expected to survive outside the lab. | ||

| + | ===Researcher Safety=== | ||

| + | *We will be working with multiply disabled strains of E. coli (which cannot survive in the gut, unlike pathogenic strains), this should render our bacteria effectively '''harmless to researchers'''. | ||

| - | == | + | ==Are your BioBrick parts safe?== |

| - | The | + | The proteins that we produce originate from an edible squid, so there should be '''no toxic or pathogenic issues''' associated with working with reflectins. We have created novel fusions of reflectins with fluorescent proteins, but there are no known safety issues with the separate proteins. The biobricks we produced thus also have no particular biosafety risks associated with them. |

| + | As a consequence, we do not think that our genetically modified bacteria could be maliciously misused in any way that could pose a security risk either. | ||

| - | == | + | ==Suggestions for the future== |

| - | + | ||

| - | + | The low-risk nature of our project is no accident; these considerations featured heavily in our [[Team:Cambridge/Brainstorm | brainstorming sessions]], and we discarded many potential project ideas because of their potential biosafety implications. This is the kind of practice we would like to encourage more iGEM teams to take seriously when choosing a project - many past project designs would not have passed our stringent biosafety checks. [[Team:Cambridge/Brainstorm#Responsibilities_when_working_with_GMOs | Check out some of our suggested guidelines.]] We also made sure to incorporate safety information for each [[Team:Cambridge/Protocols | protocol we developed]] to help future teams recognise potential hazards. | |

| - | + | ==Biosafety regulations for our project== | |

| - | + | The biological safety officer for our department is Dr Ed Tanner, so he has been the first port of call whenever anyone has had any doubts about biosafety measures. An interdepartmental team, the Cambridge Biosafety Group, has reviewed our project brief and has passed our nominations for all members of the team to be able to work with [http://en.wikipedia.org/wiki/Biosafety_level Biosafety level one] organisms in the Plant Sciences department, which is itself an approved containment level one facility. Departmental Codes of Practice for GM organisms were also consulted whilst planning our project. We have thus been cleared to work with bacteria that have been classified as being "unlikely to cause human disease". However, before carrying out any work with GM bacteria, the relevant risk assessment forms must be submitted to the Head of Group within the Department for approval. | |

| - | + | ||

| - | + | Working in the UK, there are also [http://www.hse.gov.uk/biosafety/gmo/law.htm national biosafety regulations] that we were made aware of before beginning our project. We have complied with all of these guidelines, and hence have worked well within the law. | |

| - | = | + | =Biosafety in the lab= |

| - | + | ||

| + | Genetically modified material must not be allowed to leave the laboratory. While the likelihood of the strains of bacteria with which we will be working surviving in the wild is low, every reasonable precaution must be taken to prevent such an occurrence. | ||

| + | |||

| + | Since we will only be working with biosafety level one organisms, our work can be carried out on open bench tops, but gloves and lab coats must be worn during experimentation in order to protect the worker and reduce the risk of contamination. Within the lab, 'wet' experimental work was restricted to the 'Wet Area' whereas write-ups and computing work took place solely in the 'Dry Area'. Coats, bags, laptops and other belongings were also restricted to the Dry Area. These areas were clearly segregated to ensure nothing that leaves the lab should have come into contact with biological material at any point. | ||

| + | All items which have come into contact with bacteria were autoclaved before disposal, and neither lab-coats nor gloves were allowed to leave the laboratory. | ||

| + | |||

| + | ===Waste Disposal=== | ||

| + | The proper waste disposal routes were followed stringently in order to prevent the reagents and biological material that we worked with from causing any harm to the environment or the general public. Disposing of equipment used for experimental purposes is a significant challenge, and detailed procedures are in place within the department in order to ensure the safe disposal of all materials, or their recycling where possible. The chart below outlines our departmental waste disposal policy - it is currently up on our wall in the lab. | ||

| + | [[File:cam_waste_chart.jpg|centre|720px]] | ||

| + | |||

| + | ====Autoclave==== | ||

| + | Autoclaving is a very effective method of sterilisation, and so this was executed on all materials that could possibly have come into contact with live biological matter before disposal. This was our principle method of enforcing containment over the summer. | ||

[[File:CAM SAFETY AUTOCLAVE2.JPG | frame | center | ''fig 1.''The Autoclave Room]] | [[File:CAM SAFETY AUTOCLAVE2.JPG | frame | center | ''fig 1.''The Autoclave Room]] | ||

[[File:CAM SAFETY AUTOCLAVE1.JPG | thumb | right | 150px | ''fig 2.'' Barbara Landamore, demonstrating glassware ready for autoclaving]] | [[File:CAM SAFETY AUTOCLAVE1.JPG | thumb | right | 150px | ''fig 2.'' Barbara Landamore, demonstrating glassware ready for autoclaving]] | ||

| - | + | Some very clear guidelines are enforced on the use of the autoclaving service in our department. For example, glasses for autoclaving should be: | |

| - | *Only partially filled: | + | *Only partially filled: any liquids inside will boil during autoclaving and hence expand |

*Lidded (loosely) - gas must be able to escape (to prevent explosion) | *Lidded (loosely) - gas must be able to escape (to prevent explosion) | ||

*Labelled 'iGEM' so any problems can be reported back to us | *Labelled 'iGEM' so any problems can be reported back to us | ||

| Line 41: | Line 54: | ||

*Collected from the autoclaving room | *Collected from the autoclaving room | ||

| - | Other equipment, e.g. petri dishes, should be bagged, labelled and placed in the yellow box to the right (see picture) | + | Other equipment, e.g. petri dishes, should be bagged, labelled and placed in the yellow box to the right (see picture). If the items are sharp (and hence could penetrate the autoclave bags, presenting a hazard to autoclave technicians) then they should be placed in a secure closed container before being bagged. |

| + | |||

| + | Items which are unsuitably prepared for autoclaving (e.g. loose pipette tips in bags) will be returned, and will not be autoclaved until they are prepared appropriately for the procedure. | ||

| + | |||

| + | =Minimising risks inside the lab= | ||

| - | + | Within the lab, MSDS sheets were consulted whenever we planned to use new chemicals/reagents, to ensure that all possible safety hazards had been taken into consideration before any accidents could happen. For each [[Team:Cambridge/Protocols | protocol followed]] we prepared a COSHH form for departmental records and recorded any safety issues in the relevant section of the protocol, as a reference for ourselves and future teams. | |

<br style="clear: both" /> | <br style="clear: both" /> | ||

{{Template:Team:Cambridge/CAM_2011_TEMPLATE_FOOT}} | {{Template:Team:Cambridge/CAM_2011_TEMPLATE_FOOT}} | ||

Latest revision as of 17:04, 15 September 2011

Contents |

Safety

Safety is of utmost importance during projects involving synthetic biology. Not only must the welfare of scientific and non-scientific staff within the department be considered, but also that of the wider community. Safety procedures have been prioritised from the beginning of our project and we have taken care to pick a project that poses minimal biosafety risks even in the event of accidental release from a laboratory.

Do your project ideas raise biosafety issues?

We made a point of envisioning plans for future applications that do not rely on exposing the environment or the public to genetically modified organisms. Our project creates new systems that can be used within current biosafety guidelines, rather than relying on a significant shift in policy towards release of GM organisms.

Public Safety

- Should an organism containing the reflectin production devices escape from the lab, we do not anticipate any significant hazards for the public since structural colour will not increase the host range of the host bacteria, nor alter its pathogenicity.

Environmental Safety

- Organisms with structural colour should interact with their environments in an identical way to those without, so there are no significant risks of environmental damage. We work with disabled strains which should be at a disadvantage in the natural environment and would not be expected to survive outside the lab.

Researcher Safety

- We will be working with multiply disabled strains of E. coli (which cannot survive in the gut, unlike pathogenic strains), this should render our bacteria effectively harmless to researchers.

Are your BioBrick parts safe?

The proteins that we produce originate from an edible squid, so there should be no toxic or pathogenic issues associated with working with reflectins. We have created novel fusions of reflectins with fluorescent proteins, but there are no known safety issues with the separate proteins. The biobricks we produced thus also have no particular biosafety risks associated with them. As a consequence, we do not think that our genetically modified bacteria could be maliciously misused in any way that could pose a security risk either.

Suggestions for the future

The low-risk nature of our project is no accident; these considerations featured heavily in our brainstorming sessions, and we discarded many potential project ideas because of their potential biosafety implications. This is the kind of practice we would like to encourage more iGEM teams to take seriously when choosing a project - many past project designs would not have passed our stringent biosafety checks. Check out some of our suggested guidelines. We also made sure to incorporate safety information for each protocol we developed to help future teams recognise potential hazards.

Biosafety regulations for our project

The biological safety officer for our department is Dr Ed Tanner, so he has been the first port of call whenever anyone has had any doubts about biosafety measures. An interdepartmental team, the Cambridge Biosafety Group, has reviewed our project brief and has passed our nominations for all members of the team to be able to work with [http://en.wikipedia.org/wiki/Biosafety_level Biosafety level one] organisms in the Plant Sciences department, which is itself an approved containment level one facility. Departmental Codes of Practice for GM organisms were also consulted whilst planning our project. We have thus been cleared to work with bacteria that have been classified as being "unlikely to cause human disease". However, before carrying out any work with GM bacteria, the relevant risk assessment forms must be submitted to the Head of Group within the Department for approval.

Working in the UK, there are also [http://www.hse.gov.uk/biosafety/gmo/law.htm national biosafety regulations] that we were made aware of before beginning our project. We have complied with all of these guidelines, and hence have worked well within the law.

Biosafety in the lab

Genetically modified material must not be allowed to leave the laboratory. While the likelihood of the strains of bacteria with which we will be working surviving in the wild is low, every reasonable precaution must be taken to prevent such an occurrence.

Since we will only be working with biosafety level one organisms, our work can be carried out on open bench tops, but gloves and lab coats must be worn during experimentation in order to protect the worker and reduce the risk of contamination. Within the lab, 'wet' experimental work was restricted to the 'Wet Area' whereas write-ups and computing work took place solely in the 'Dry Area'. Coats, bags, laptops and other belongings were also restricted to the Dry Area. These areas were clearly segregated to ensure nothing that leaves the lab should have come into contact with biological material at any point. All items which have come into contact with bacteria were autoclaved before disposal, and neither lab-coats nor gloves were allowed to leave the laboratory.

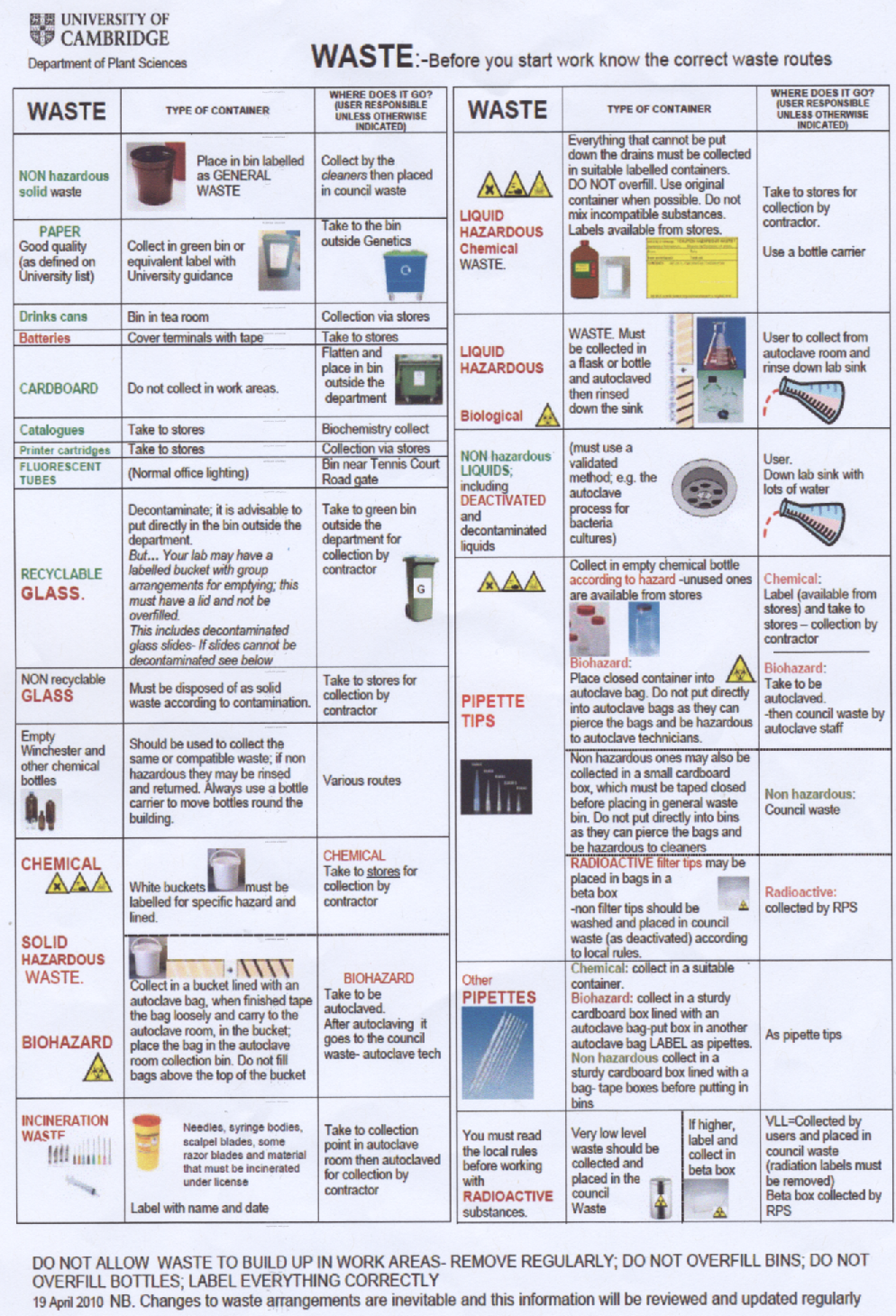

Waste Disposal

The proper waste disposal routes were followed stringently in order to prevent the reagents and biological material that we worked with from causing any harm to the environment or the general public. Disposing of equipment used for experimental purposes is a significant challenge, and detailed procedures are in place within the department in order to ensure the safe disposal of all materials, or their recycling where possible. The chart below outlines our departmental waste disposal policy - it is currently up on our wall in the lab.

Autoclave

Autoclaving is a very effective method of sterilisation, and so this was executed on all materials that could possibly have come into contact with live biological matter before disposal. This was our principle method of enforcing containment over the summer.

Some very clear guidelines are enforced on the use of the autoclaving service in our department. For example, glasses for autoclaving should be:

- Only partially filled: any liquids inside will boil during autoclaving and hence expand

- Lidded (loosely) - gas must be able to escape (to prevent explosion)

- Labelled 'iGEM' so any problems can be reported back to us

- Left on the table to the right (see picture)

- Collected from the autoclaving room

Other equipment, e.g. petri dishes, should be bagged, labelled and placed in the yellow box to the right (see picture). If the items are sharp (and hence could penetrate the autoclave bags, presenting a hazard to autoclave technicians) then they should be placed in a secure closed container before being bagged.

Items which are unsuitably prepared for autoclaving (e.g. loose pipette tips in bags) will be returned, and will not be autoclaved until they are prepared appropriately for the procedure.

Minimising risks inside the lab

Within the lab, MSDS sheets were consulted whenever we planned to use new chemicals/reagents, to ensure that all possible safety hazards had been taken into consideration before any accidents could happen. For each protocol followed we prepared a COSHH form for departmental records and recorded any safety issues in the relevant section of the protocol, as a reference for ourselves and future teams.

"

"