Team:Washington/Alkanes/Future

From 2011.igem.org

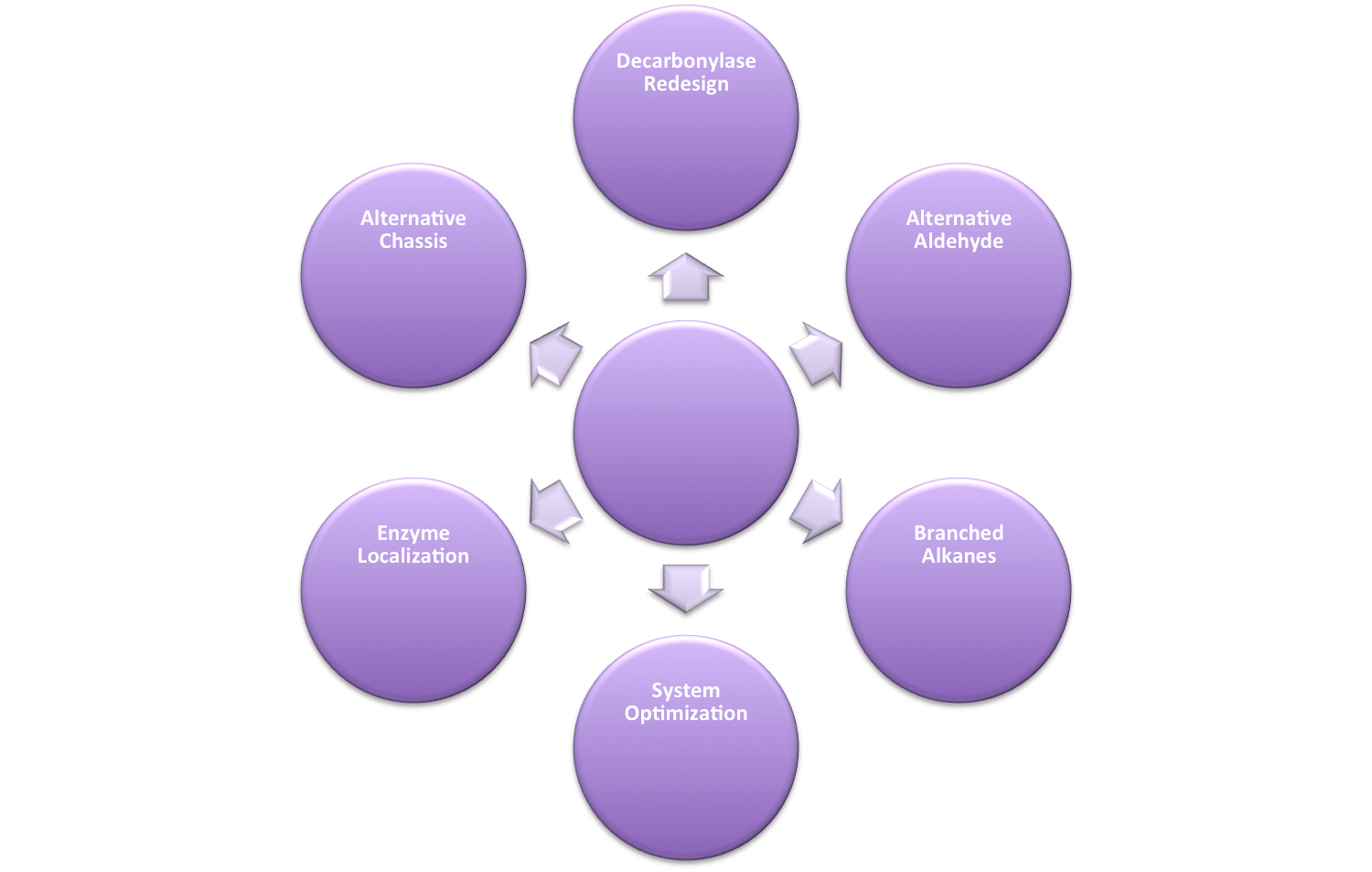

- Our current in vivo system only efficiently makes C15 alkanes. To be efficient enough for factory production, there are two broad goals to be done: 1. increase production efficiency 2. Diversity the range of alkanes for the system. 3. Increase scale of system for industrial processes. We have already begun efforts to expand the efficiency and scope of alkane production.

- One way to diversify the kind of alkanes produced is to alter the substrate specificity of the proteins involved. We decided to alter the aldehyde decarbonylase to produce shorter-chain fatty aldehydes.

- Another way to diversify our system is to use alternative proteins. Our current system uses acyl-ACP reductase, and we've identified an hypothetical alternative system that produces aldehydes: LuxCDE, made from parts from the 2010

- Our system is only capable of producing unbranched alkanes, as the cell mainly utilizes straight chained fatty acids. However, fuel we use are also composed largely of branched alkanes that affect very important properties of the fuel such as flash point and freezing point. If our fuels are truly intended to be synthesized in bacteria, we need to work on methods of making those crucial branched chained alkanes. We explored FabH2, a protein that when involved in fatty acid synthesis makes branched fatty acids.

INSERT IN THESE PAGES... LOOK AT OTHER PAGES FOR EXAMPLES OF FORMATING AND INSERTING PICTURES. CLICK THE EDIT BUTTON ON THE UPPER LEFT SIDE OF THE PAGE AFTER YOU HAVE SIGNED IN.

"

"