Team:Lethbridge/Results

From 2011.igem.org

Liszabruder (Talk | contribs) |

Liszabruder (Talk | contribs) |

||

| Line 33: | Line 33: | ||

<br> | <br> | ||

<BLOCKQUOTE> | <BLOCKQUOTE> | ||

| + | |||

| + | =Part: BBa_K542010 - Enhanced Lumazine Synthase (ELS)= | ||

| + | |||

| + | Datasheet for <html><a href="http://partsregistry.org/Part:BBa_K542010"><font color="blue">Part BBa_I716462</font></a></html> in <i>E. coli</i> strain BL21 (DE3). | ||

| + | <br> | ||

| + | [[image:uoflELSdatasheet.png|center|150px]] | ||

| + | |||

| + | ==Introduction== | ||

| + | Lumazine synthase (LS) from <i>Aquifex aeolicus</i> forms icosahedral microcompartment (MC) assemblies of 60 or 180 monomeric units that self assemble and are capable of isolating proteins from their local environment. As shown in previously published work (1), the LS protein has been mutated so that the interior of the MC is negatively charged; the UL 2009 iGEM team has submitted the mutated LS gene to the parts registry (BBa_K249002). A negatively charged interior allows for preferential compartmentalization of positively charged molecules, which can easily be engineered through the addition of a poly-arginine tag to a target protein (1). The size of the cavity of the Lumazine Synthase microcompartment was enlarged and the negative charge was increased via directed evolution (2). The compartment formed by this polypeptide has a larger cavity and a larger net negative charge, thus allowing a larger loading capacity into the cavity of the compartment. | ||

| + | <br><br> | ||

| + | The part was synthesized by Bio Basic Inc. into the pET28a plasmid vector (which allows for expression of ELS with an N-terminal His-tag). The Enhanced Lumazine Synthase (ELS) was moved into the pSB1C3 vector by the Lethbridge 2011 team. | ||

| + | ==Characterization== | ||

| + | ===Overexpression=== | ||

| + | The His-tagged ELS in pET28a was transformed into <i>E. coli</i> BL21 (DE3) and overexpressed. | ||

| + | ====Materials and Methods==== | ||

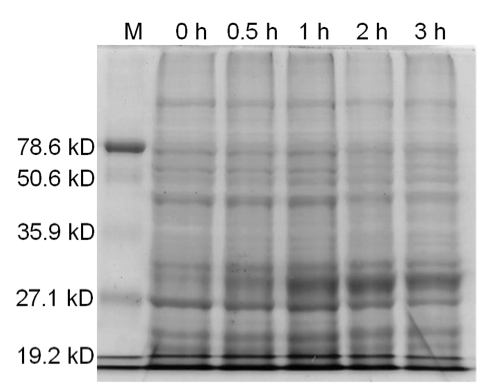

| + | 4 X 500 mL of LB media in 2 L flasks were inoculated with <i>E. coli</i> BL21 (DE3) cells expressing ELS. Cells were grown at 37°C with shaking until the culture reached an OD<sub>600</sub> of 0.683. The cultures were then induced with 10 mM IPTG. Culture samples containing equal amounts of cells were taken before induction and 30 min, 1 hour, 2 hours, and 3 hours post induction for analysis by SDS-PAGE. At 5 hours post induction the cells were harvested by centrifugation at 5000 x g for 5 min. The cell lysate was resuspended in 42 mL of buffer containing 50 mM Tris pH 8.0, 60 mM NH<sub>4</sub>CL, 7 mM β-mercaptoethanol, 1 mM PMSF, 7 mM MgCl<sub>2</sub>, 300 mM KCl, 10 mM imidazole, and 15% glycerol. Afterwards, 0.05 g of crystallized lysozyme was added to the cell suspension and incubated on ice for 1 hour. The lysate was then centrifuged for 70 minutes at 30000 x g to obtain the S30 fraction. | ||

| + | ====Results==== | ||

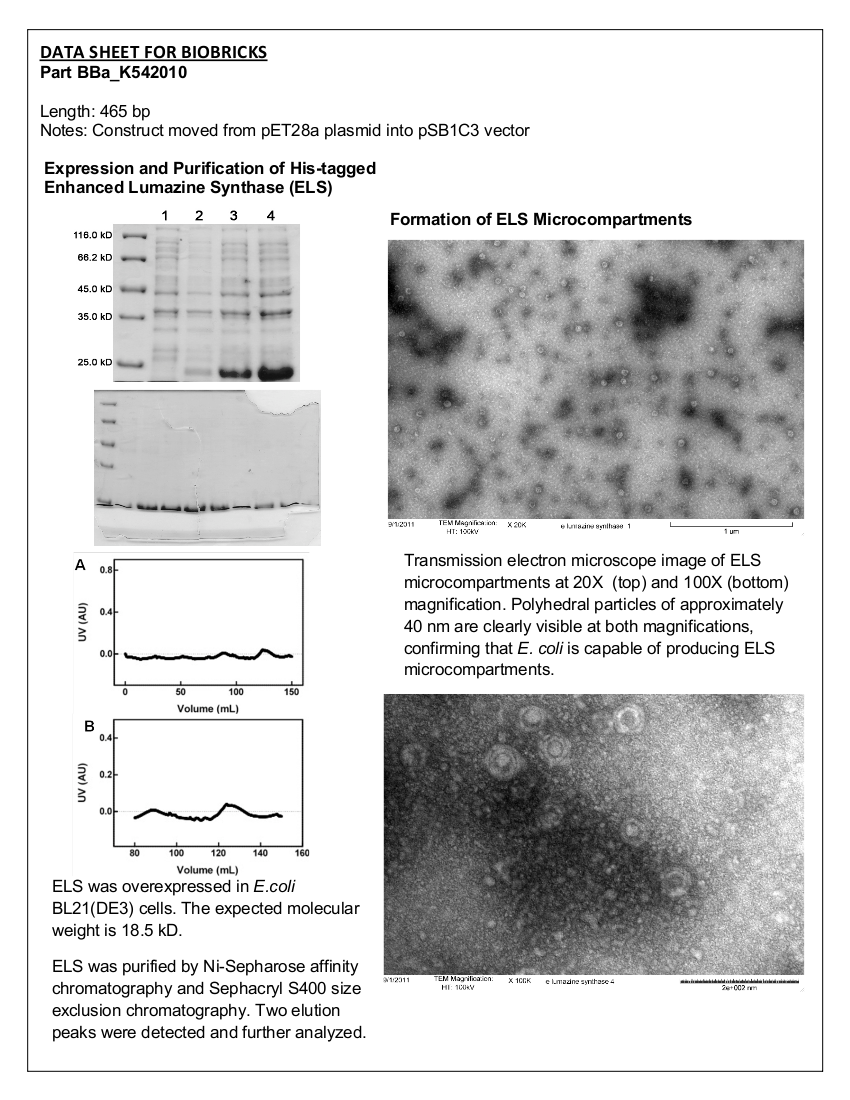

| + | [[image:uoflELSexpressiongel.png|center]] | ||

| + | <br><br> | ||

| + | <b>Figure 1.</b> 12.5% SDS-PAGE of His-tagged ELS Overexpressed in <i>E. coli</i> BL21 (DE3). Samples were taken at 1 hour increments after IPTG induction. Lane 1: zero hours; Lane 2: 1 hour; Lane 3: 2 hours; Lane 4: 3 hours. The expected molecular weight of enhanced lumazine synthase is 18.5 kD. | ||

| + | ====Conclusion==== | ||

| + | Figure 1 clearly displays an increase in expression of a protein smaller than 25.0 kD, which is approximately the expected size of enhanced lumazine synthase monomers (18.5 kD). | ||

| + | ===Protein Purification=== | ||

| + | Enhanced lumazine synthase microcompartments were purified using size exclusion chromatography (SEC) to determine if the purified ELS formed a homogenous mixture of compartments, heterogenous mixture of microcompartments, or remained in monomer form. | ||

| + | ====Materials and Methods==== | ||

| + | In order to obtain a sample of ELS that was near homogeneity for characterization with SEC, the ELS sample was first purified by immobilized metal-ion affinity chromatography (IMAC). Ni<sup>2+</sup>-Sepharose beads supplied by Sigma Aldrich were pre-swelled in buffer containing 20% ethanol and 1mM NaCl. 3.75 mL of the Ni<sup>2+</sup>-Sepharose slurry was added to a 50 mL falcon tube. The beads were centrifuged at 500 x g for 2 min and the ethanol-containing buffer decanted. The beads were washed with 3 bed volumes of sterile water. The column was then washed in 6 bed volumes of Buffer A containing 50 mM Tris pH 8.0, 60 mM NH<sub>4</sub>CL, 7 mM β-mercaptoethanol, 1 mM PMSF, 7 mM MgCl<sub>2</sub>, 300 mM KCl, 10 mM imidazole, and 15% glycerol. S30 cell extract was applied to the column and mixed gently. The resin-S30 extract suspension was incubated on ice for 1 hour. The mixture was centrifuged at 500 x g for 2 min and the supernatant decanted. The supernatant was kept for further analysis by SDS-PAGE. The resin was washed 3 times with a full falcon tube volume (50 mL) of Buffer A. The mixture was centrifuged at 500 x g for 2 min and the supernatant decanted. The supernatant was kept for further analysis by SDS-PAGE. The column was washed 4 times with a full falcon tube volume (50 mL) of Buffer B (Buffer A plus 20 mM imidazole). The mixture was centrifuged at 500 x g for 2 minutes and the supernatant decanted. The supernatant was kept for further analysis by SDS-PAGE. The protein was eluted 9 times using 90% bed volume of Buffer E (Buffer A plus 250 mM imidazole). After each wash the sample was kept for analysis by SDS-PAGE. | ||

| + | <br><br> | ||

| + | Fractions 1 – 9 were pooled and concentrated using a Vivaspin Column with a 10 kDa molecular weight cut-off. | ||

| + | <br><br> | ||

| + | Concentrated protein samples from the Ni<sup>2+</sup>-Sepharose column were applied to a Sephacryl S400 size exclusion chromatography column at a flow rate of 0.4 mL/minute. 150 mL of SEC Buffer (50 mM sodium phosphate, 5 mM EDTA, 200 mM NaCl, pH 8.0, with 20% glycerol) was pumped through the column. The fractions eluted were collected and the absorbance was measured at 280 nm (see Fig 3 and 4). | ||

| + | ====Results==== | ||

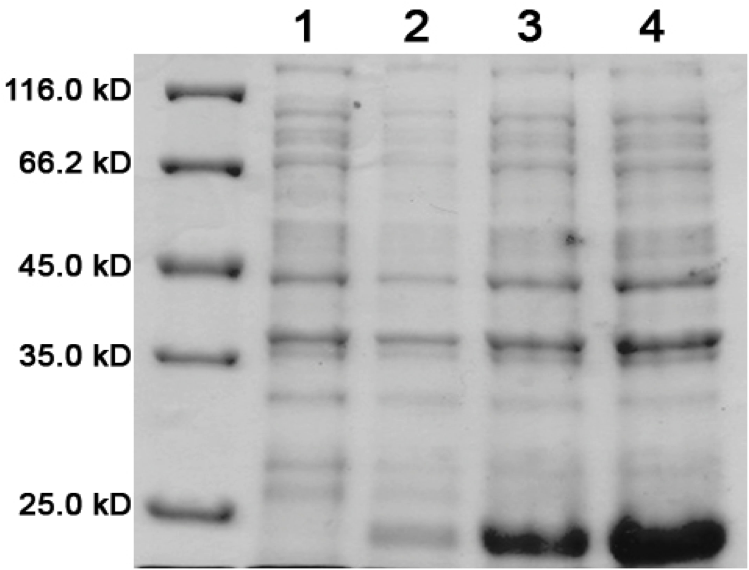

| + | [[image:uoflELSsdspageimac.png|center]] | ||

| + | <br> | ||

| + | <b>Figure 2.</b> SDS-PAGE (15%) of ELS purification by IMAC. Lane 1: protein marker. Lanes 2-10: Elution Fractions 1 – 9. | ||

| + | <br><br> | ||

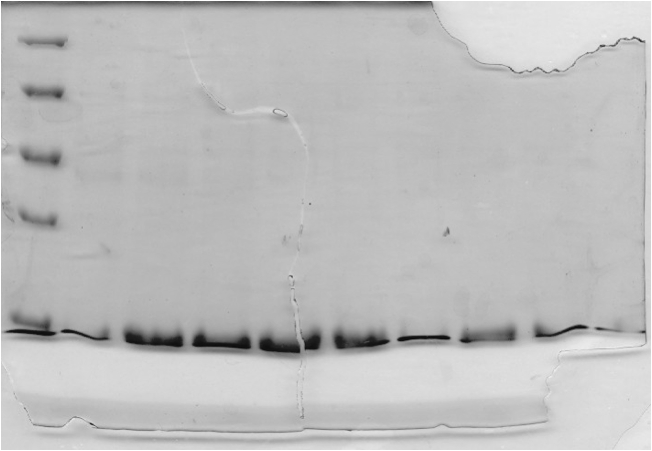

| + | [[image:uoflELSchromatograms.png|center]] | ||

| + | <br> | ||

| + | <b>Figure 3.</b> (A) Concentrated protein sample from the Ni<sup>2+</sup>-Sepharose column applied to a Sephacryl S400 size exclusion chromatography column at a flow rate of 0.4 mL/minute. The absorbance of the eluting solution was measured at 280nm. (B) Magnified view of chromatogram of the two peaks seen in (A). | ||

| + | ====Conclusion==== | ||

| + | Figure 2 shows that with each wash proteins of a similar size were eluted off the resin. These proteins run at the expected molecular weight of enhanced lumazine synthase monomers (18.5 kD). | ||

| + | <br><br> | ||

| + | The chromatogram (Figure 3) from the chromatography experiment displays two regions of increased absorbance at 280 nm, between 82 and 135 mL of buffer eluted. These fractions were pooled, concentrated, and analyzed using transmission electron microscopy. | ||

| + | ===Transmission Electron Microscopy=== | ||

| + | Purified samples of enhanced lumazine synthase from size exclusion chromatography (SEC) were characterized using transmission electron microscopy. We viewed samples of each of the two peaks from the SEC; however only one sample contained microcompartments. | ||

| + | ====Materials and Methods==== | ||

| + | Purified Samples in solution were placed on a carbon grid and negatively stained using uranyl acetate. Carbon grids containing the samples were then viewed with a Hitachi H-7500 Transmission Electron Microscope. | ||

| + | ====Results==== | ||

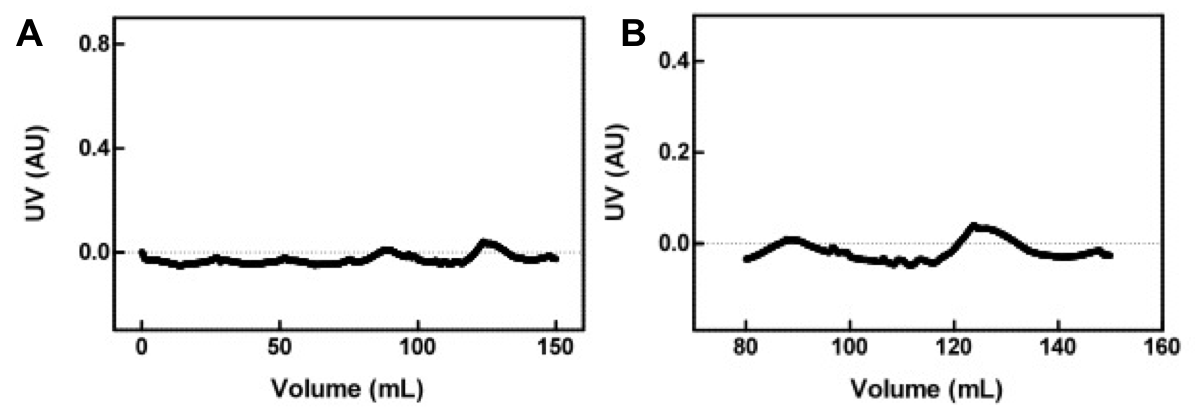

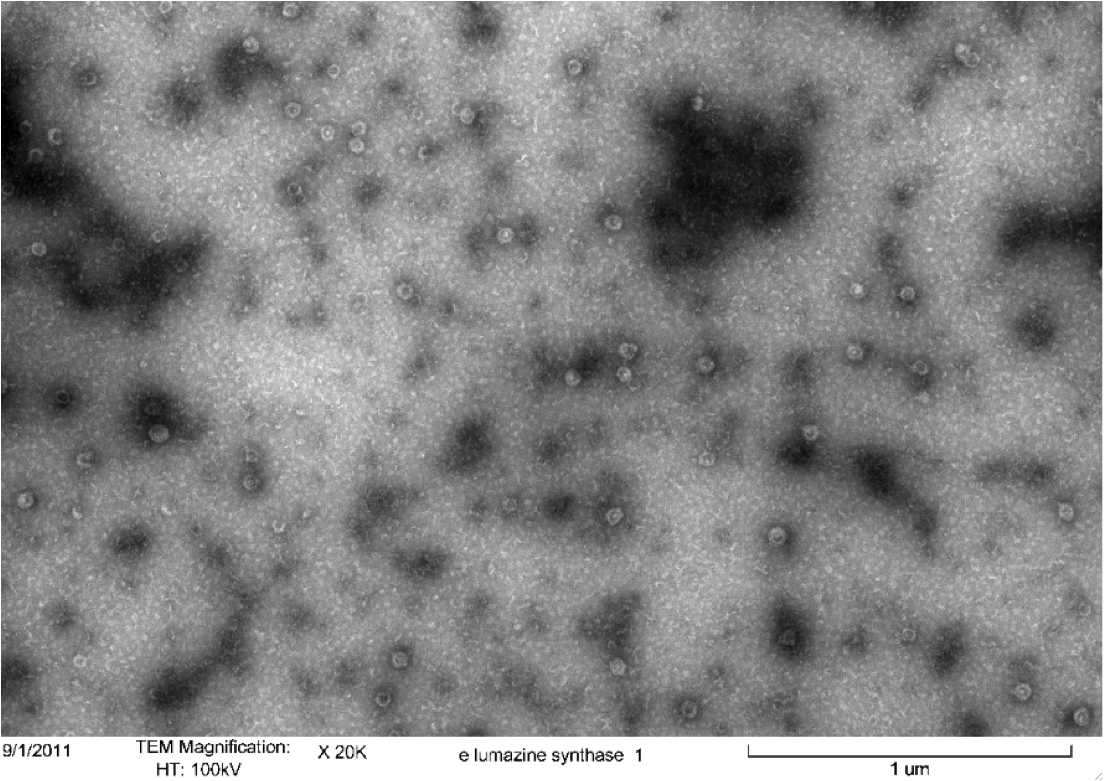

| + | [[image:uoflELSTEM1.png|center]] | ||

| + | <br> | ||

| + | <b>Figure 4.</b> Transmission electron microscopy of Enhanced Lumazine Synthase microcompartments. Microcompartments of approximately 40 nm can be seen at x 20K magnification. | ||

| + | <br><br> | ||

| + | [[image:uoflELSchromatograms.png|center]] | ||

| + | <br> | ||

| + | <b>Figure 5.</b> Transmission electron microscopy of Enhanced Lumazine Synthase microcompartments. Microcompartments of approximately 40 nm can be seen at x 100K magnification. | ||

| + | ====Conclusion==== | ||

| + | As expected, TEM micrographs show polyhedral particles of approximately 40 nm, corresponding to the size described by Wörsdörfer et al. (2011). This confirms that E. coli is capable of producing enhanced lumazine synthase. | ||

| + | ==References== | ||

| + | |||

| + | (1) Viadiu H, Aggarwal AK (2000). Structure of BamHI bound to nonspecific DNA: a model for DNA sliding. Mol. Cell 5 (5): 889-895. | ||

| + | <br> | ||

| + | (2) iGEM 2007. (2011, May 10). BerkiGEM2007Present5. Retrieved from http://parts.mit.edu/igem07/index.php/BerkiGEM2007Present5. | ||

| + | |||

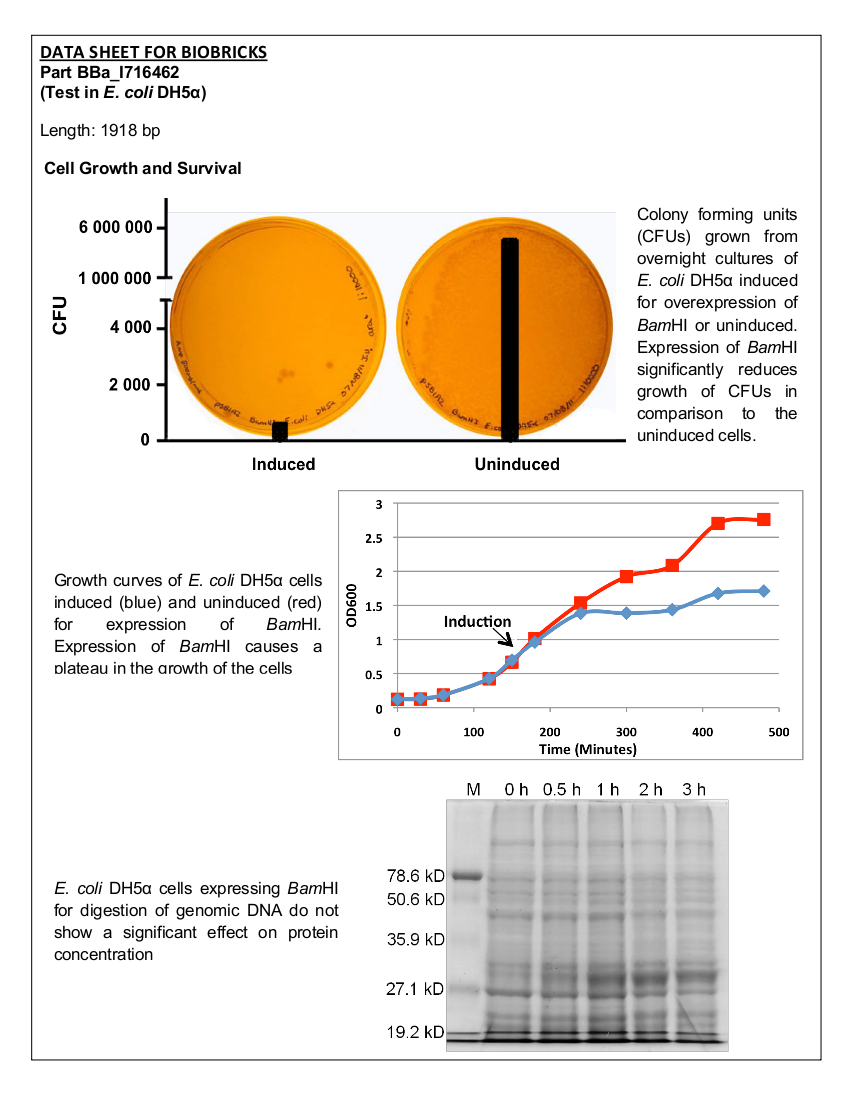

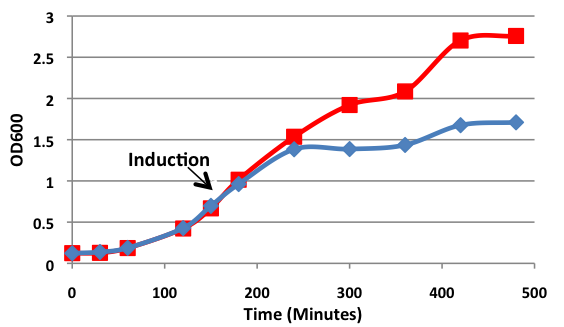

=<font color="black">Part: BBa_I716462 – <i>Bam</i>= | =<font color="black">Part: BBa_I716462 – <i>Bam</i>= | ||

Revision as of 15:57, 28 September 2011

|

|

|

|---|

"

"